High-strength alloy-containing polishing head of cmp apparatus

A high-strength alloy, polishing head technology, used in electrical components, working carriers, semiconductor/solid-state device manufacturing, etc., can solve the problems of poor polishing process and powder flying, and achieve the goal of improving bad processes, preventing powder flying, preventing crack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] First, reference numerals are attached to constituent elements in each drawing, and the same numerals are used as much as possible for the same constituent elements even in different drawings. In addition, when describing the present invention, if it is judged that a detailed description of a known function or structure is not necessary for the gist of the present invention or obscures the present invention, the detailed description will be omitted.

[0039] Hereinafter, preferred embodiments of the present invention will be described in more detail with reference to the accompanying drawings.

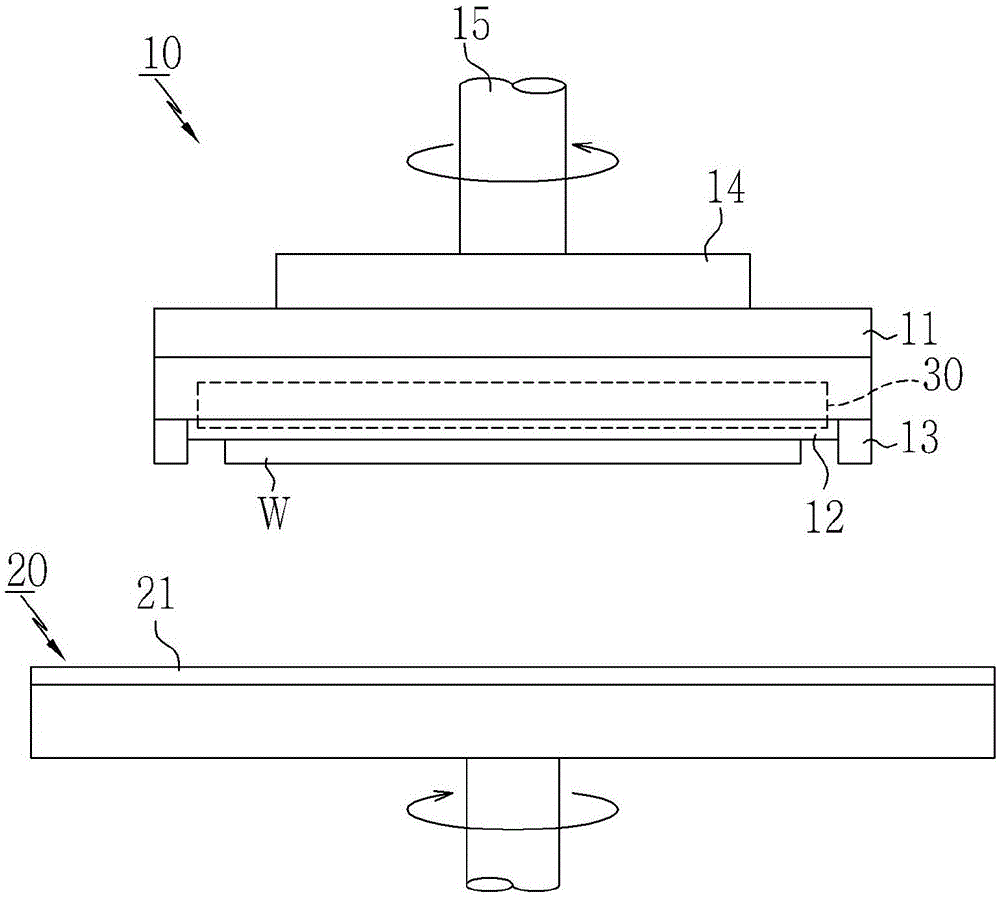

[0040] Figure 4 It is a side structural view of the circular perforated plate of the present invention, Figure 5 (a) (b) is the upper and lower sectional views of the circular perforated plate of the present invention, Figure 6 It is an exploded cross-sectional view of the circular perforated plate of the present invention.

[0041]As shown in the figure, the polishing hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com