Ground rotation type carbon dioxide colloid gas aphrons extinguishing bomb

A carbon dioxide and colloidal foam technology, applied in fire prevention equipment, fire rescue, etc., can solve problems such as difficulty in ensuring uniform mixing and spraying, difficulty in generating colloidal substance gas, and reduced fire extinguishing ability, so as to achieve stable colloidal foam and improved fire extinguishing effect , the effect of rapid fire extinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

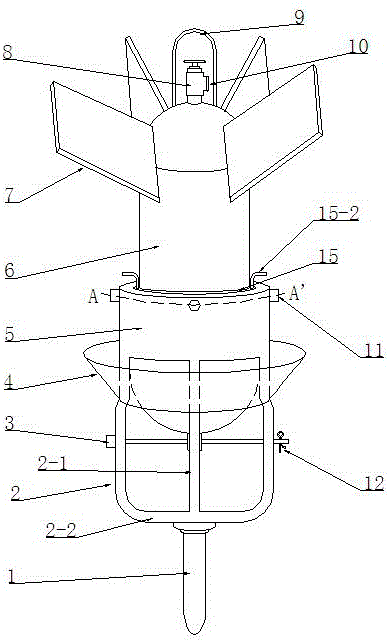

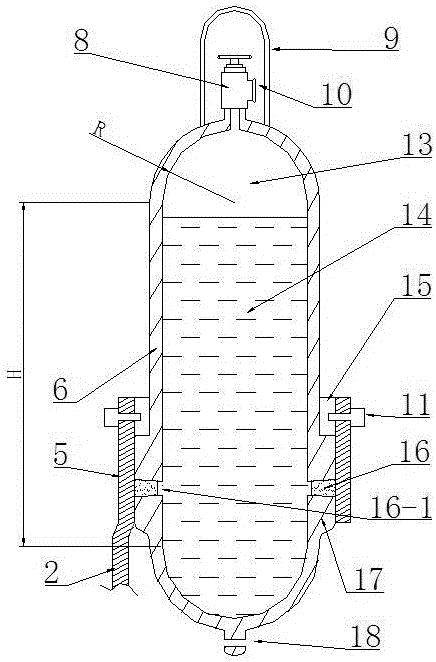

[0049] Embodiment 1 (small artificial throwing fire extinguishing bomb, volume 1.2L)

[0050] 1. Put the bracket ( Figure 5 ) on the scale, such as figure 1 , Chassis 2 is placed on the support ring 20 of bracket 19.

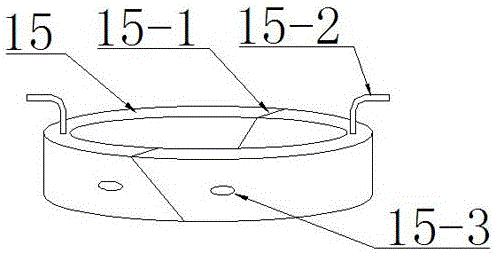

[0051] 2. If Figure 4 , loosen the limit bolt 11, remove the positioning ring 15, plug the nozzle 16-1 of the projectile body 6 with the sealing plug 16 first, let the end (big head) of the sealing plug 16 leak a little, and apply a little lubricant Agent, then bullet is inserted in the gland 5, penetrates lock bar 3, until the opposite side of chassis 2 is passed through the lock bar hole 18 at the top of the bullet, and is fixed with fixing pin 12.

[0052] 3. Reset the positioning ring 15, align the limit bolt 11 with the thread hole 15-3 of the positioning ring (15), and tighten the limit bolt 11.

[0053] 4. Close the feeding valve 8, connect the carbon dioxide gas source to the feeding port 10, open the feeding valve 8 and the carbon dioxide gas sour...

Embodiment 2

[0060] Embodiment 2 (Large helicopter throws fire extinguishing bombs, volume 24, 120L)

[0061] 1. For 120L fire extinguishing bombs, put the bracket ( Figure 5 ) on the scale, such as figure 1 , Chassis 2 is placed on the support ring 20 of bracket 19.

[0062] 2. If Figure 4 , loosen the limit bolt 11, remove the positioning ring 15, lift the projectile 6 through the lifting ring 9, first use the sealing plug 16 to plug the nozzle 16-1 of the thickened part 17 of the side wall of the projectile, and let the sealing plug 16 The end (big head) leaks a little bit, and apply a little lubricant, then insert the warhead into the pressure sleeve 5, penetrate the lock bar 3, pass through the lock bar hole 18 at the top of the warhead until it passes through the opposite side of the chassis 2, and use the fixing pin 12 fixed.

[0063] 3. Reset the positioning ring 15, align the limit bolt 11 with the thread hole 15-3 of the positioning ring (15), tighten the limit bolt 11, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com