Automatic pipe-cleaning water-cutting oil-returning method and system for multiple storage tanks

An automatic cleaning and storage tank technology, applied in separation methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems of medium loss environment, pollution, disturbance of oil-water interface, etc., to prevent oily medium from cutting water and avoid environmental pollution. Pollution, the effect of efficient water cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

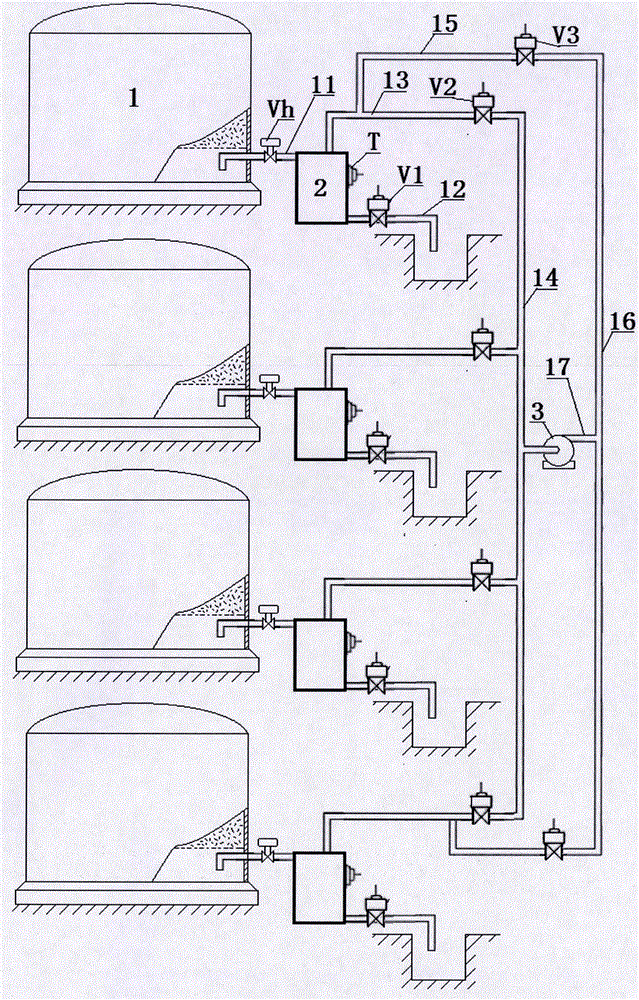

[0022] Embodiment one, such as figure 1 As shown, the multi-storage tank automatic pigging, water cutting and oil return method of the present invention is that the respective siphon drain pipes 11 (or straight discharge drain pipes) of multiple storage tanks 4 storing similar media are respectively equipped with manual valves Vh, and are connected to each other respectively. The upper part of the water cutter 2 equipped with the medium detection head T; the lower two parts of the water cutter are connected to the water cutting pipe 12 equipped with the water cutting control valve V1, and the top of the water cutter 2 is respectively connected through the front oil return branch pipe 13 equipped with the front oil return control valve V2 The front oil return collecting pipe 14, the front oil return branch pipes 13 of any two water cutters 2 are respectively connected to the rear oil return branch pipe 15 of the rear oil return control valve V3 upstream of the oil return control...

Embodiment 2

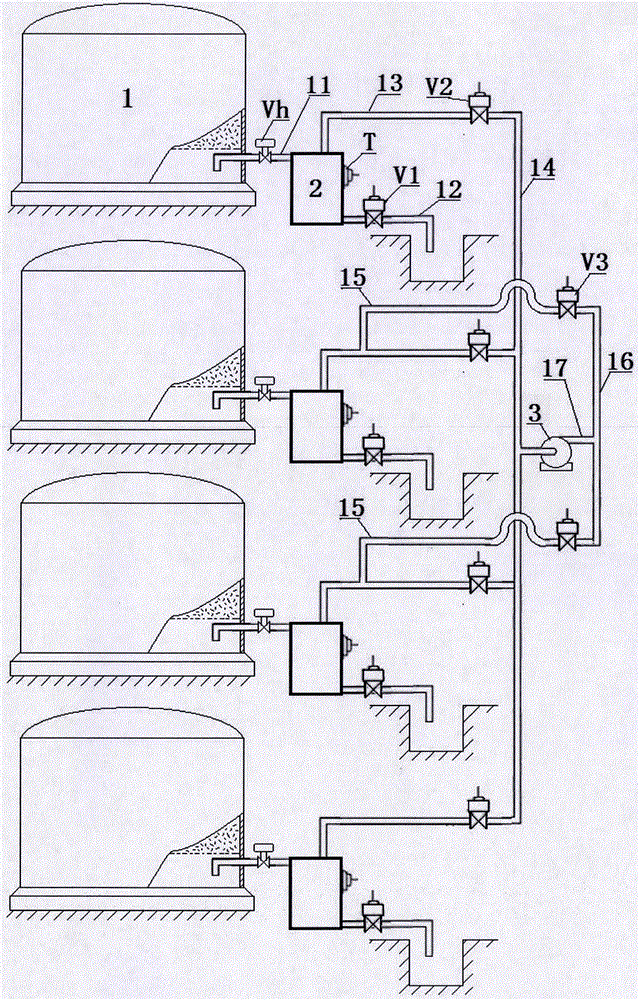

[0035] Embodiment two, such as figure 2 As shown, the difference between the multi-storage tank automatic pigging method and system for automatic pigging, cutting water and oil return of the present invention and Embodiment 1 is that the storage tanks 4 are the 1st-N storage tanks 4 arranged in sequence from front to back, and are respectively separated by siphon Type drain pipe 11, water cutter 2 and front oil return branch pipe 13 are connected to the front oil return collecting pipe 14 from front to back; the front oil return branch pipe 13 of the middle two storage tanks 4 is connected to the rear oil return branch pipe 15, and the middle two storage tanks 4 extend The front oil return collection pipe section between the two front oil return branch pipes 13 in the middle is connected to the rear oil return collection pipe 16 through the front and back oil return pipes 17 connected in series of the oil return pump 3 .

Embodiment 3

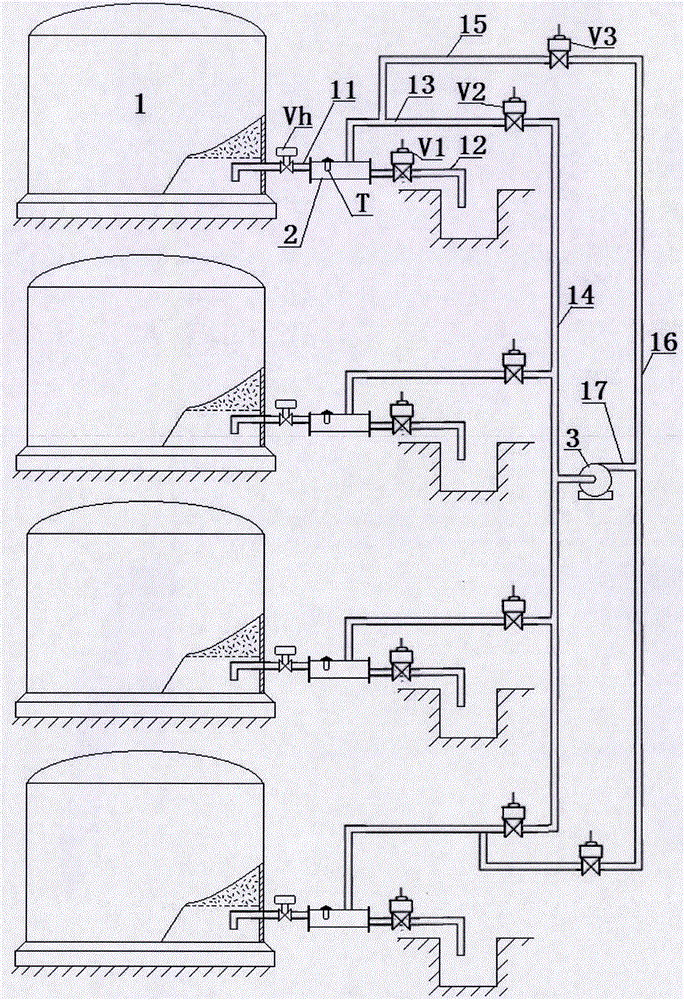

[0036] Embodiment three, such as image 3 As shown, the difference between the multi-storage tank automatic pigging, water cutting and oil return method and system of the present invention and the first embodiment is that the medium detection head T is configured to be inserted and installed downward from the upper middle of the thick horizontal pipe water cutter 2 body. The resistive or dielectric constant type medium detection probe T.

[0037] After adopting the above technical solution, the multi-storage tank automatic pigging method and system for water cutting and oil return of the present invention have the advantages of not only preventing oily medium from cutting water, but also timely concentrated and efficient water cutting and smooth flow of water cutting and oil return pipelines.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap