System for emulsification of environment-friendly glue

A glue and environmental protection technology, applied in cleaning methods and utensils, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as pipe blockage, and achieve the effect of preventing pipe blockage, cleaning thoroughly, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

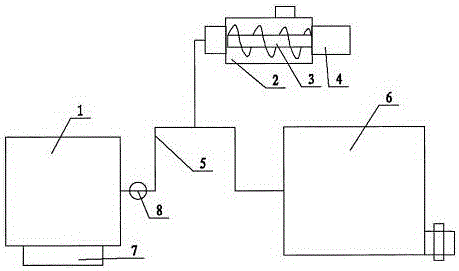

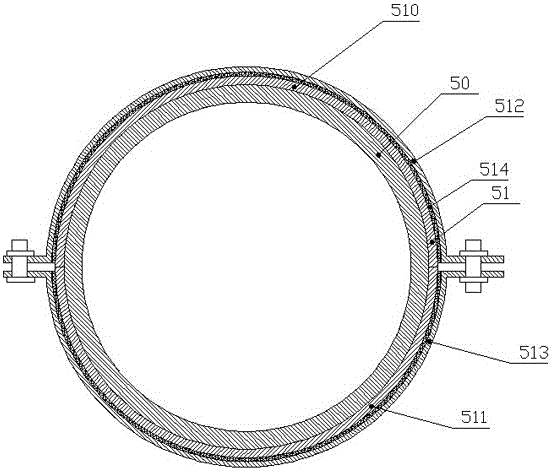

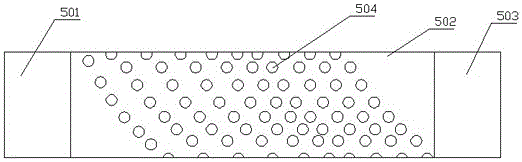

[0019] A system for the emulsification of environmentally friendly glue, including a mixing tank 1, a material injection device 2, a delivery pipeline 5 and an emulsification tank 6, an electric heater 7 is installed at the bottom of the mixing tank 1, and the mixing tank 1 is connected to the emulsification through the delivery pipeline 5 Tank 6, a pump 8 is installed at the outlet of the mixing tank 1, a screw blade shaft 3 is arranged inside the injection device 2, and the rear end of the screw blade shaft 3 is connected to the motor 4, and the discharge port of the injection device 2 is connected to the delivery pipeline 5, and its It is characterized in that: the delivery pipeline 5 includes an inner tube 50 and an outer tube 51, the inner tube 50 is sleeved in the outer tube 51, the inner tube 50 includes a head 501, a middle part 502 and a tail 503, and the middle part 502 is uniformly arranged There are a plurality of through holes 504, and the outer tube 51 includes an...

Embodiment 2

[0022] This embodiment is basically the same as Embodiment 1, except that the through holes 504 are helically distributed on the middle portion 502 of the inner tube 50 .

[0023] The diameter of the through hole 504 is 50 mm.

Embodiment 3

[0025] In this embodiment, on the basis of Embodiment 1 or Embodiment 2, the diameter of the through hole 504 is 30 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com