Mechanical and electronic integrated rapid paint spraying device

A fast, electromechanical technology, applied in spraying devices, devices for coating liquid on the surface, spray booths, etc., can solve the problems of step separation, affect work efficiency, and consume a lot of time to achieve fast drying of paint and simple structure , easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

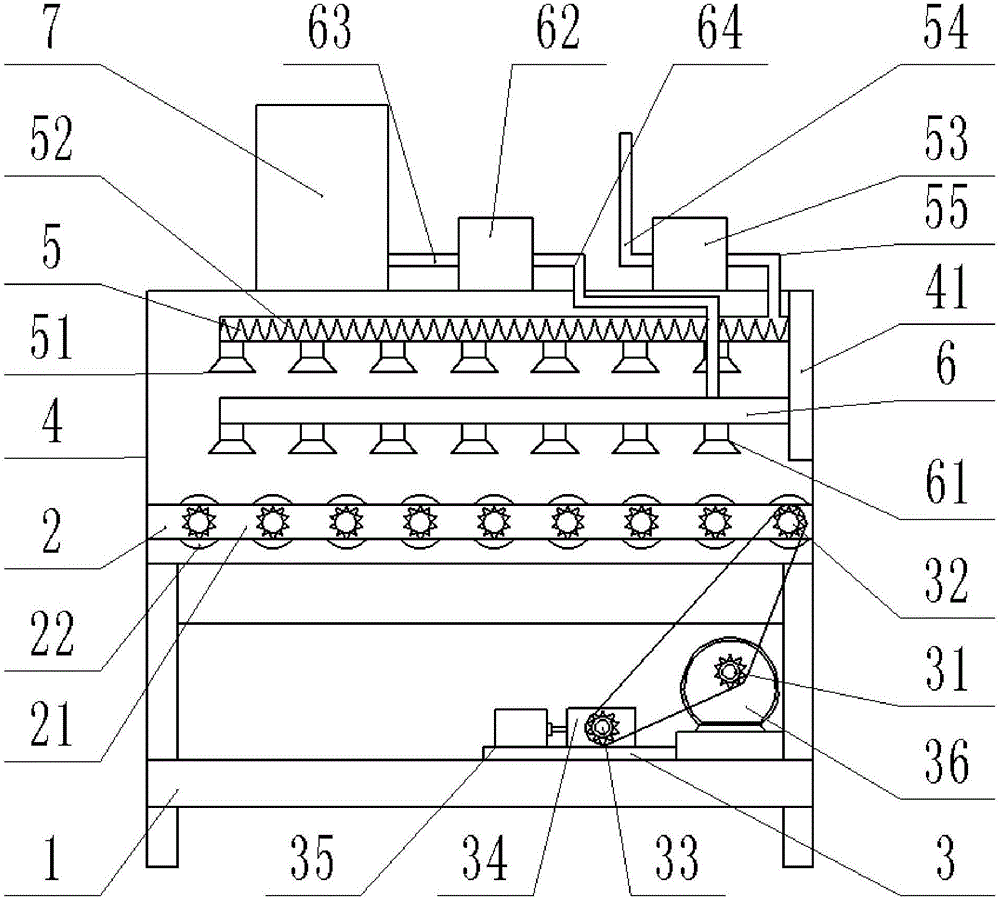

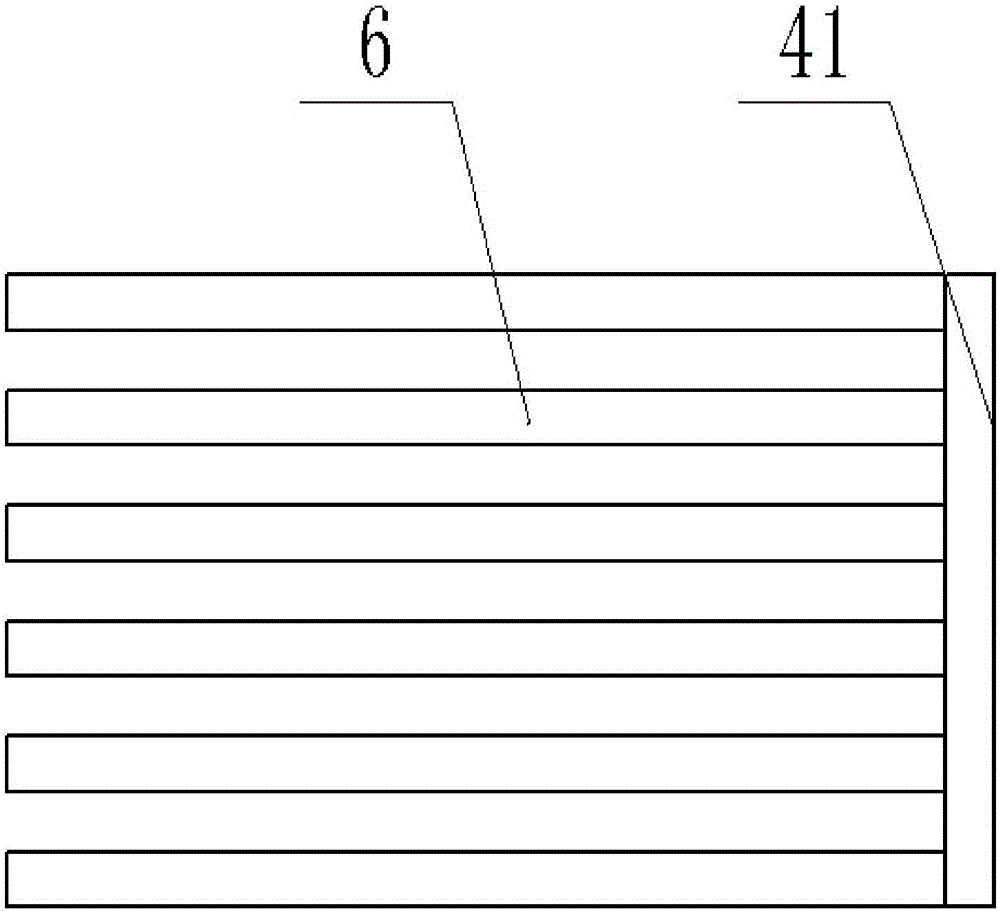

[0016] see Figure 1-2 , a mechatronics rapid painting device, comprising a frame 1, a roller line 2 and a paint spray booth 4, a roller line 2 is erected above the frame 1, and the roller line 2 includes a bracket 21 and is installed on the bracket 21 A number of rollers 22, the support 21 is fixedly connected above the frame 1; a drive motor 36 is installed on the frame 1, and the drive motor 36 drives and connects the roller line 2 through the sprocket mechanism 3, and the sprocket mechanism 3 includes a driving wheel 31, Driven pulley 32 and tension pulley 33, tension pulley 33 is connected on the frame 1 by slippage of tension slide block 34, and frame 1 is provided with the linear motor 35 that is used to drive tension slide block 34; Sprocket drive structure Simple, mature technology, easy maintenance, through the setting of the tensioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com