Inertia removal device and weight grading scale

A technology for rejecting devices and sorting scales, which is applied in packaging, packaging protection, transportation and packaging, etc. It can solve the problems of large space occupation, long reset time, and large aerodynamic noise, and achieves small footprint and quiet sorting action , the effect of small aerodynamic noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

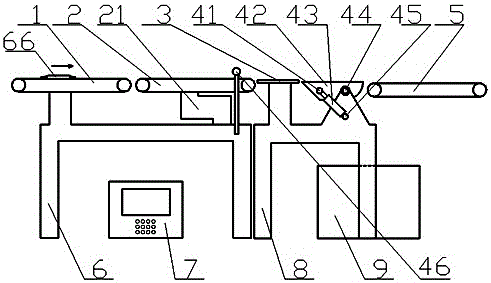

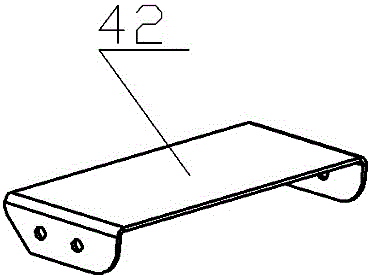

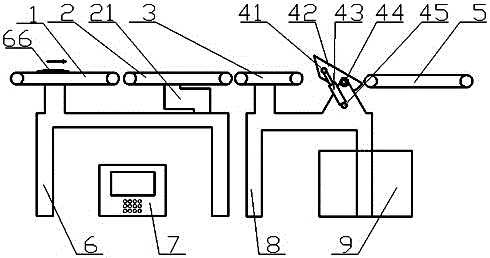

[0064] Embodiment 1: as figure 1 , 2 As shown, a weight sorting scale includes a frame 6 and a control cabinet 7, a feeding unit 1, and a weighing unit 2 arranged on the frame 6, and also includes at least one sorting mechanism, and each sorting mechanism corresponds to At least one receiving unit is set, and the sorting mechanism includes a support 8, a slide rail 42, the upper surface and the lower surface of the slide rail 42 are smooth slideways, the slide rail 42 is connected with the support 8 by a rotating shaft 44, and on the support 8 An overturn driving mechanism is provided to drive the slide rail 42 to rotate around the rotating shaft 44, and the feeding unit 1, the weighing unit 2, and the overturn driving mechanism are electrically connected to the control cabinet 7 respectively. The arrow points to the running direction of the object or the incoming material direction of the object.

[0065] A time-delay protection unit 3 is also arranged between the weighing ...

Embodiment 2

[0072] Embodiment 2: The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is: as Figure 4 As shown, a weight sorting scale, the delay protection unit 3 is a belt conveyor, and the belt conveyor is electrically connected to the control cabinet 7 .

Embodiment 3

[0073] Embodiment 3: The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is: as Figure 5As shown, a weight sorting scale has no delay protection unit 3 between the weighing unit 2 and the sorting mechanism; the feeding unit 1, the weighing unit 2, and the sorting mechanism are arranged in sequence, and stop at the slide rail 42 When the first static position, that is, the upper surface of the sliding rail 42 driven by the turning drive mechanism is in line with the incoming material direction of the object, and the object can slide smoothly from the upper surface of the sliding rail 42, the position of the object entrance on the upper surface of the sliding rail 42 is slightly lower. The position at the exit of the weighing unit 2 object.

[0074] This solution is suitable for rechecking that the weighing platform of the weighing unit 2 is very long or the output speed of the weighing result is very fast, so that the control cabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com