A chemical-mechanical grinding device with no rotating end point

A chemical machinery and grinding device technology, applied in the direction of grinding devices, grinding machine tools, metal processing equipment, etc., can solve the problems of excessive movement of the grinding head, production capacity impact, cable damage logic, etc., to reduce design difficulty and high utilization efficiency , to avoid the effect of no-load phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

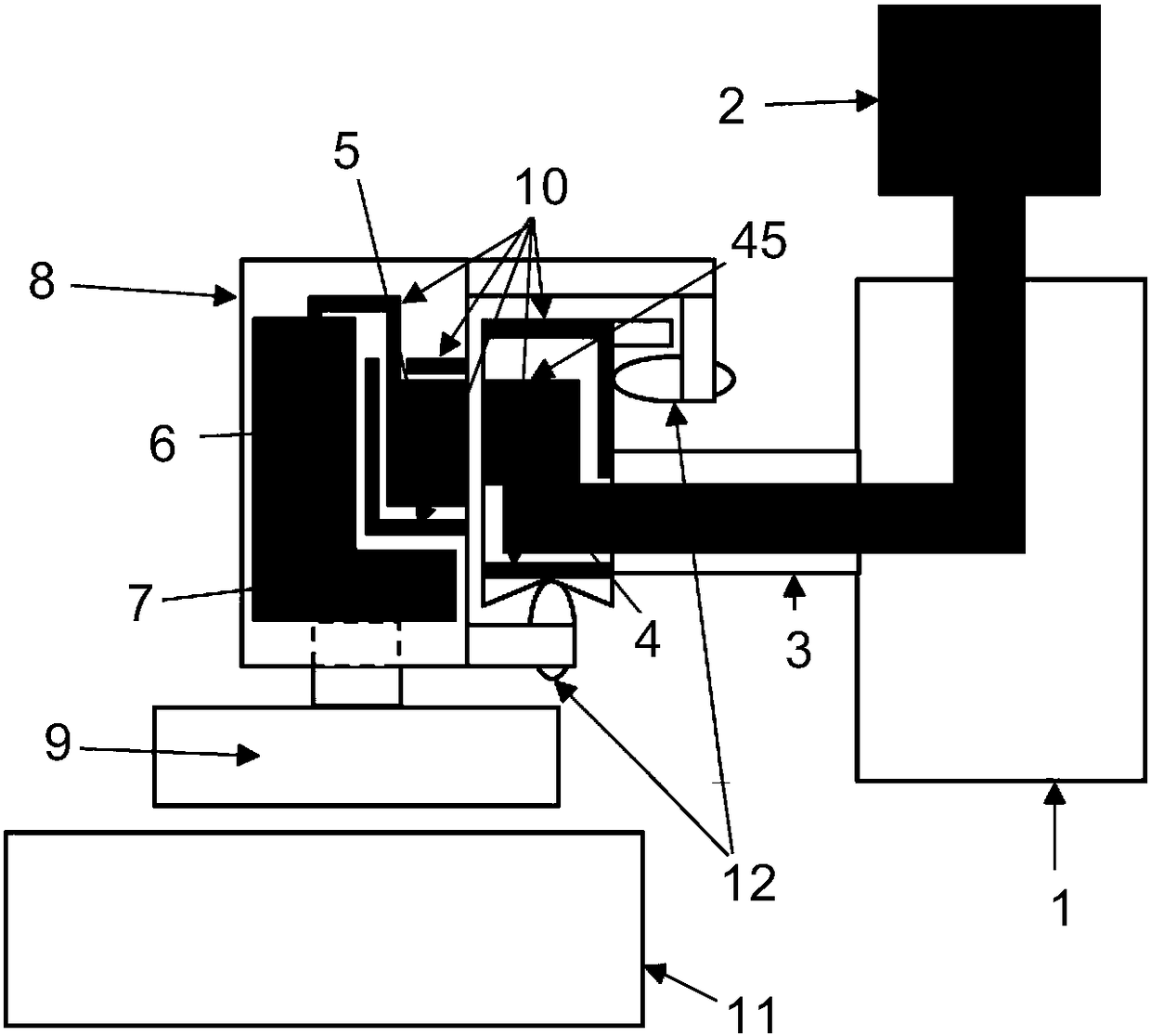

[0029] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

[0030] It should be noted that in the following specific embodiments, when the embodiments of the present invention are described in detail, in order to clearly show the structure of the present invention for ease of description, the structure in the drawings is not drawn according to the general scale. Partial enlargement, deformation, and simplification of processing have been implemented. Therefore, this should be avoided as a limitation of the present invention.

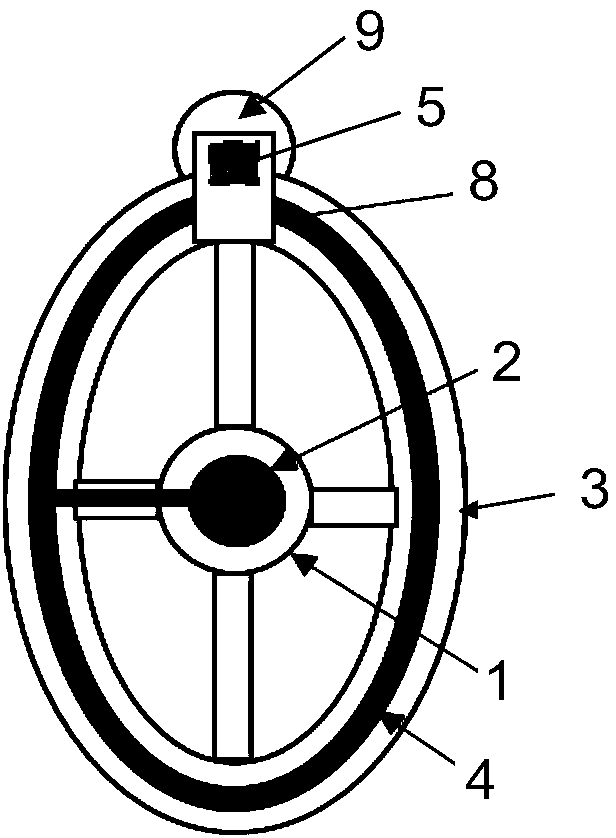

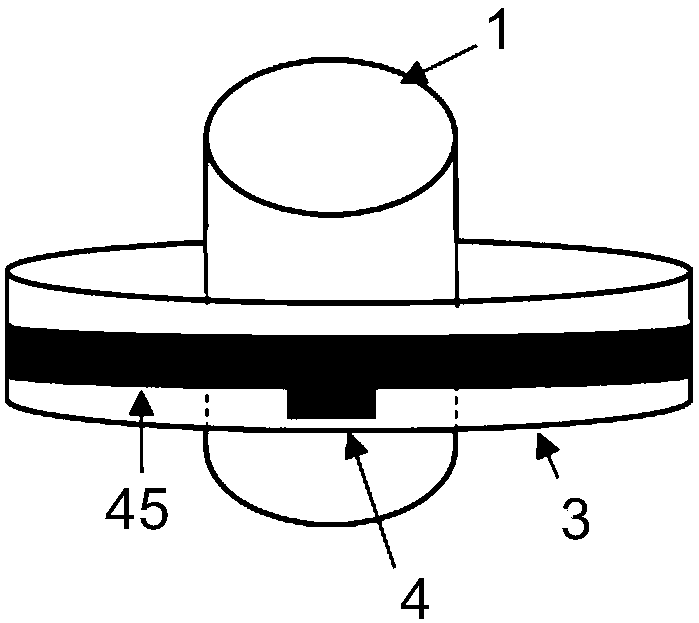

[0031] In the following specific embodiments of the present invention, please refer to figure 1 , figure 1 It is a top view of the structure of a chemical mechanical polishing device without a rotating end point according to a preferred embodiment of the present invention. Such as figure 1 As shown, a chemical mechanical polishing device without a rotation end point of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com