A rigid leveling mechanism for the printing platform in a 3D printer

A printing platform, rigid technology, applied in the direction of 3D object support structure, process efficiency improvement, manufacturing tools, etc., can solve problems such as increased product size error, rough surface, and printed product influence, and achieves convenient leveling operation, Improved dimensional accuracy and surface smoothness for quick work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

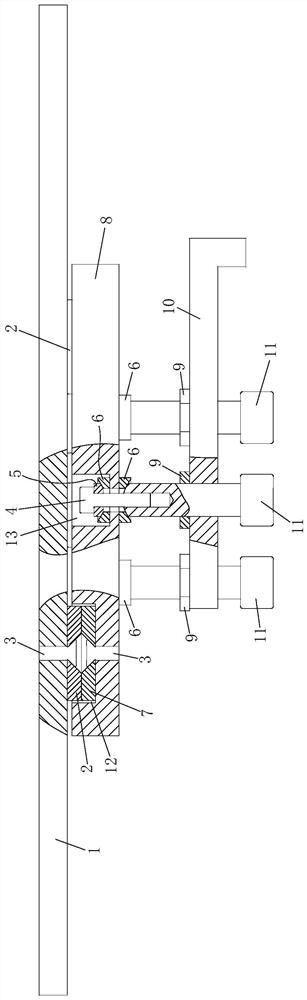

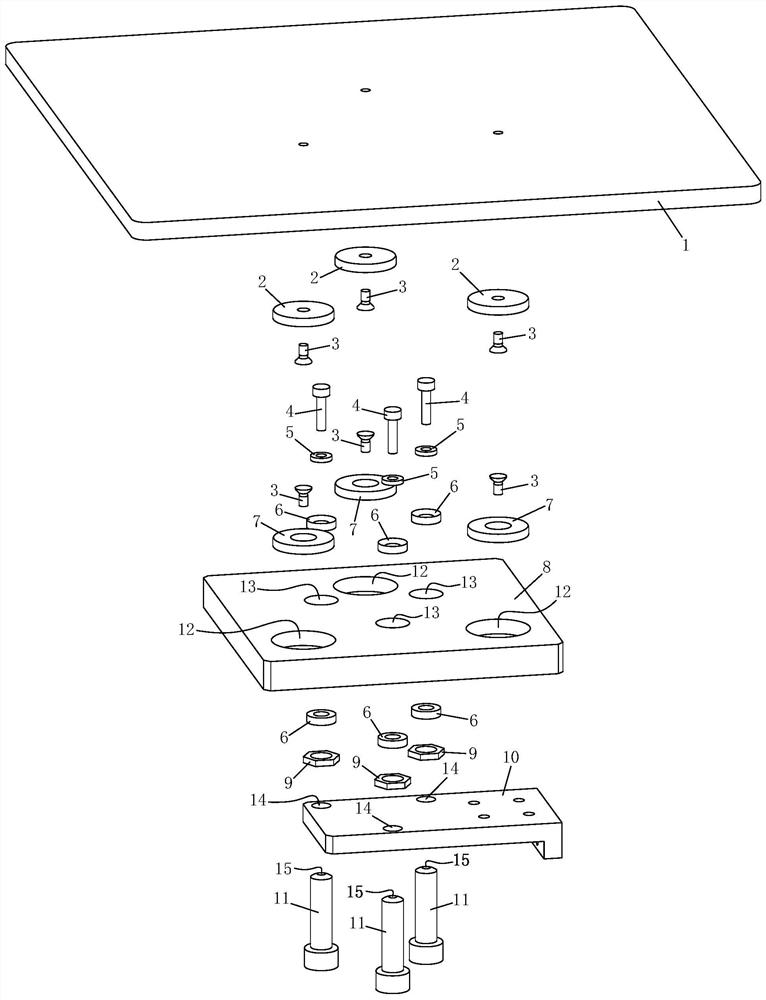

[0012] Example: see figure 1 and figure 2 , a rigid leveling mechanism for a printing platform in a 3D printer, including a fixing plate, the fixing plate is provided with three screw holes, the centerlines of the three screw holes are not on the same plane, and the screw holes are screwed with leveling screws And the leveling screw is locked on the fixing plate by a nut, the thread head end of the leveling screw is arc convex, and a small screw hole is arranged in the center, and the small screw hole is screwed with a small screw; There is a backing plate above, and the backing plate is provided with small screw countersunk holes corresponding to three leveling screws. The upper and lower ports of the small screw countersunk holes are provided with grooved gaskets, and the grooved gaskets at the upper port are concave. The groove is upward, the groove of the grooved gasket at the lower port is downward, the end of the arc convex thread head of the leveling screw is placed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com