Vacuumized adsorption bottom surface type automobile emergency braking and turnover and drifting preventing device

An emergency braking and vacuuming technology, applied in the direction of brakes, braking components, tractors, etc., can solve the problems of long braking distance, uneven tire force, side drift, rollover, etc., to prevent rollover and drift. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

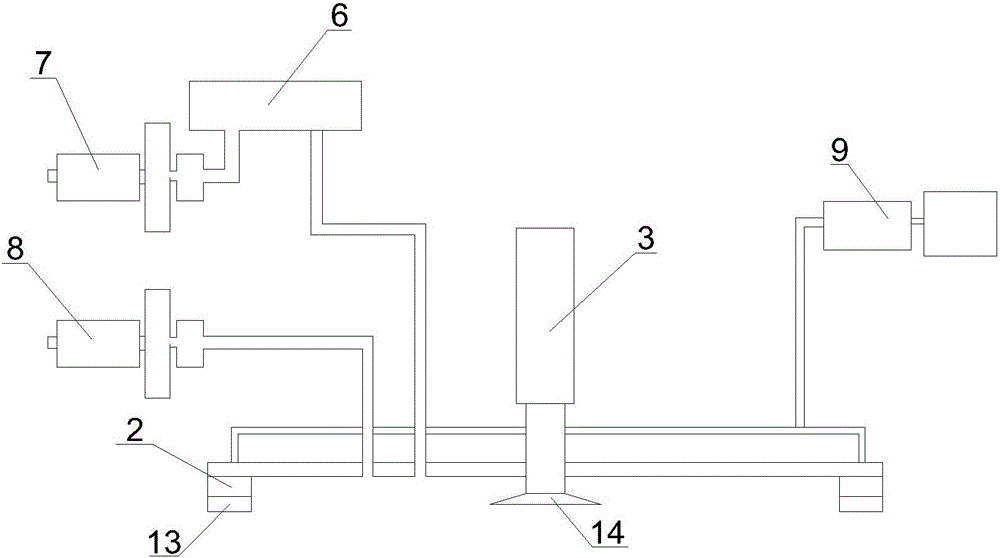

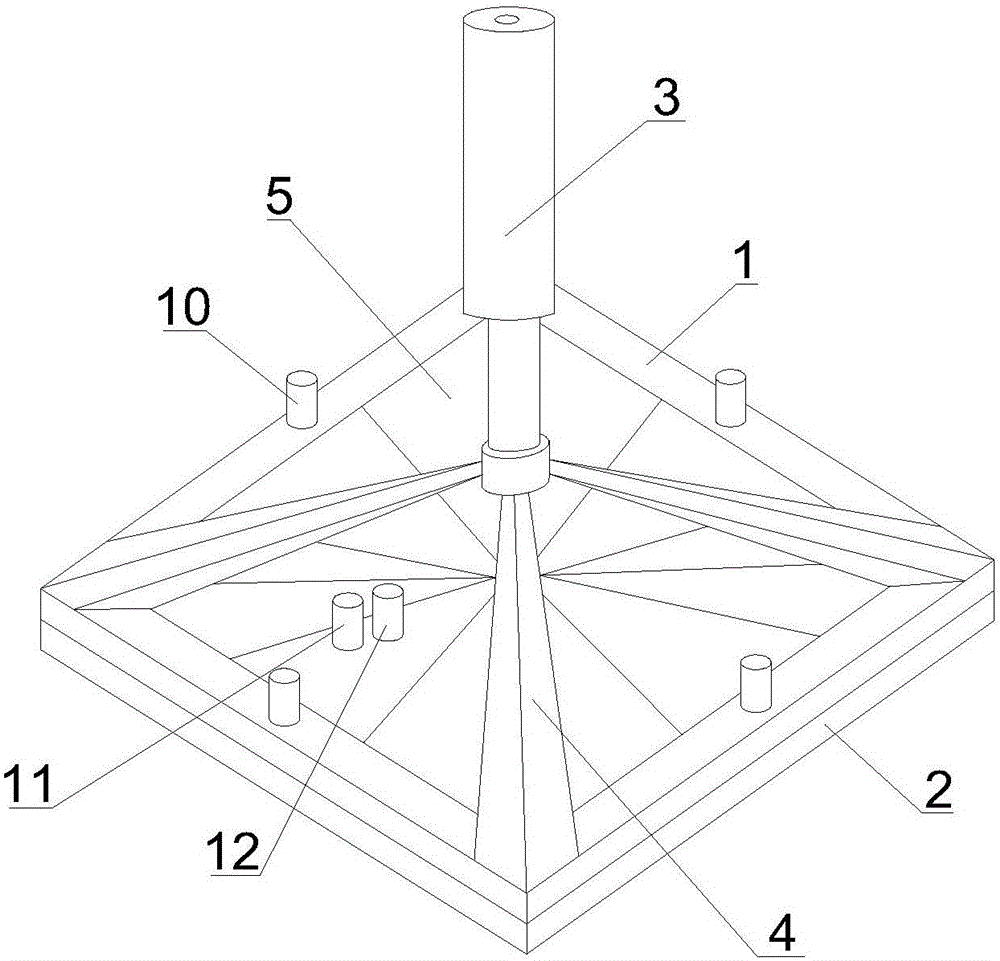

[0019] Such as figure 1 As shown, the present invention is a vacuum suction bottom surface type automobile emergency braking and anti-rollover, drifting device, which is characterized in that it includes a vacuum body, a main vacuum pump 8, a vacuum tank 6, an auxiliary vacuum pump 7 and a lifting connection device 3, the vacuum body It is fixed on the chassis of the automobile by the lifting connection device 3 arranged vertically, the main negative pressure port 11 of the vacuum body is communicated with the suction port of the main vacuum pump 8 through the pipeline, and the auxiliary negative pressure communicated with the vacuum tank 6 is provided on the vacuum body port 12, the vacuum tank 6 communicates with the suction port of the auxiliary vacuum pump 7.

[0020] The inner hollow body forms a closed space after contacting the ground. The main vacuum pump 8 is used to extract the air in the inner hollow body. The vacuum tank 6 is in a negative pressure state at ordina...

Embodiment 2

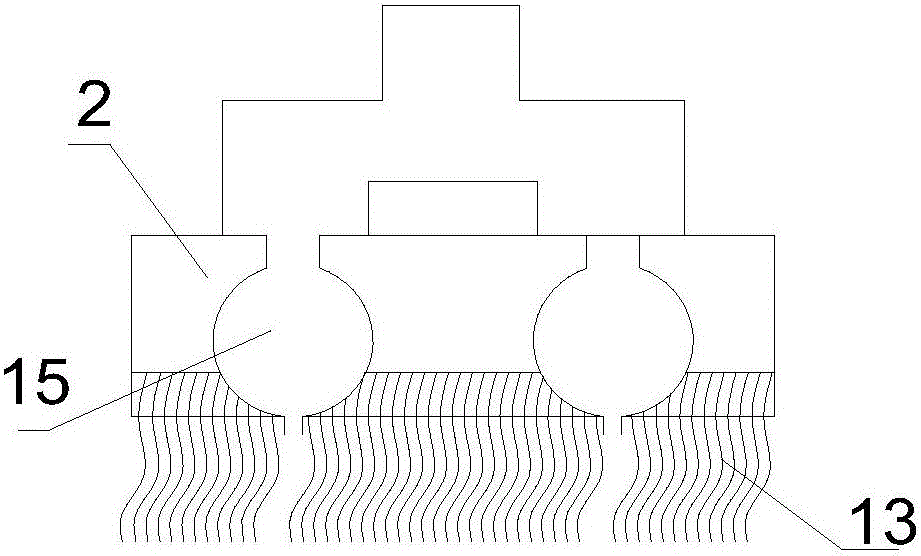

[0023] Compared with Embodiment 1, this embodiment differs in that the vacuum body also includes a soft material layer 13, a viscous liquid delivery pipe 15 and a viscous liquid delivery pump 9, and the soft material layer 13 is fixedly arranged under the isolation layer 2. On the end face, the viscous liquid delivery pipe 15 is horizontally arranged in the isolation layer 2, the liquid inlet 10 of the viscous liquid delivery pipe 15 passes through the barrier body 1 and communicates with the viscous liquid delivery pump 9, and the lower part of the viscous liquid delivery pipe 15 is arranged There are a plurality of liquid outlets 16 located in the soft matter layer 13 .

[0024] Such as Figure 4 As shown, the viscous liquid delivery pump 9 is used to transport the viscous liquid to the ground through the corresponding pipeline and the spout soft material layer 13 to fill the gap. When the car is braked, the isolation layer 2 is in contact with the ground, so that the inner...

Embodiment 3

[0026] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the vacuum body also includes a pressure-bearing column 14, and the pressure-bearing column 14 is vertically arranged in the barrier body 1, and the upper end of the pressure-bearing column 14 is in contact with the barrier body 1. The upper side is fixedly connected, and the lower end surface of the pressure bearing column 14 is provided with a plurality of cones for increasing the frictional force with the ground.

[0027] The pressure-bearing column 14 mainly bears the pressure on the ground formed by the negative pressure of the inner hollow body, and its ground contact friction body (the pressure-bearing column 14 and the ground contact end) is composed of multiple cone-shaped bodies made of hard materials (metal, rubber) The contact surface can maximize the friction with the ground. If it is used on ice and snow roads, a steel nail-shaped contact surface can also be used.

[0028] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com