Garbage bag fixing device for automatic packaging bag replacing garbage can

A technology for fixing garbage bags and garbage bins, which is applied to garbage bins, garbage collection, household appliances, etc. It can solve problems such as unreliability, garbage overflow, and impact on the living environment, and achieve reliable and stable adsorption, high automation, and precise control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

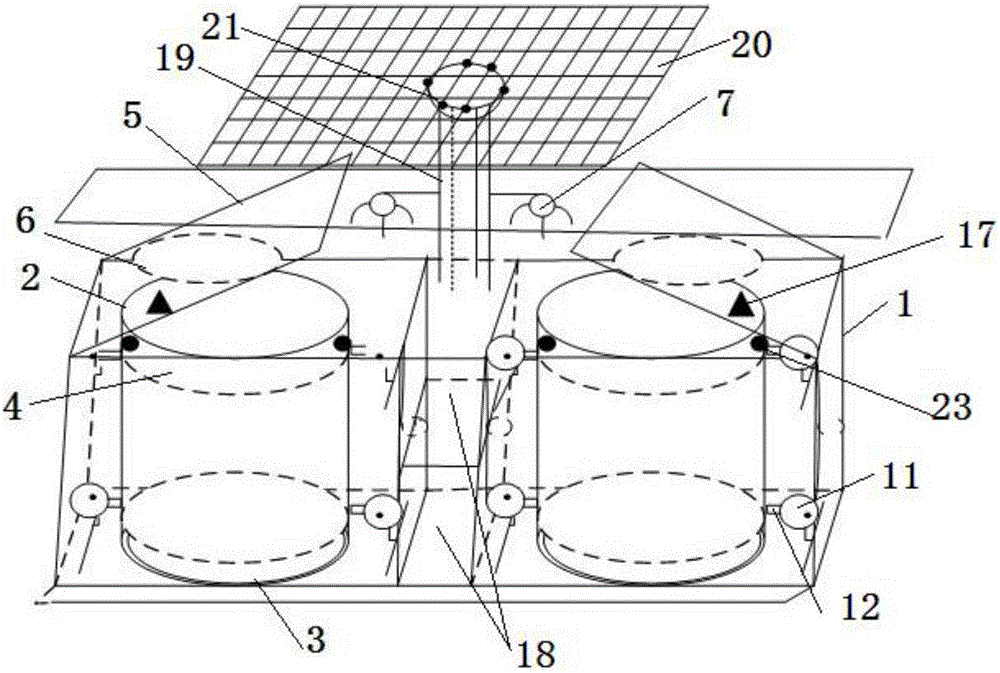

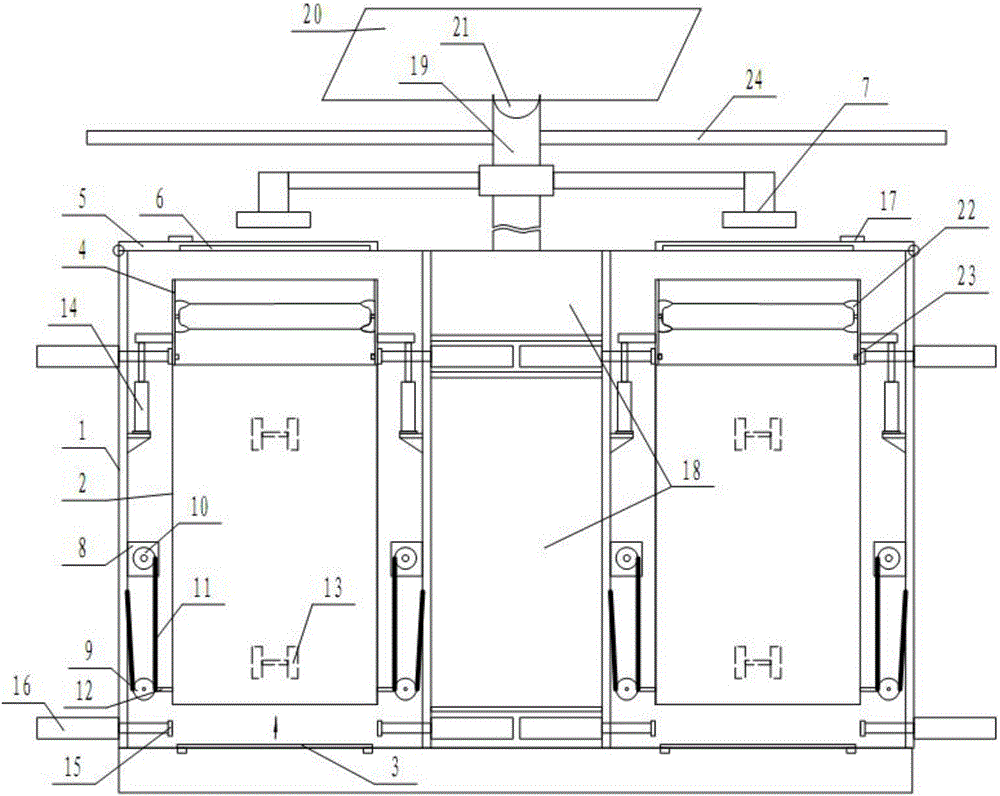

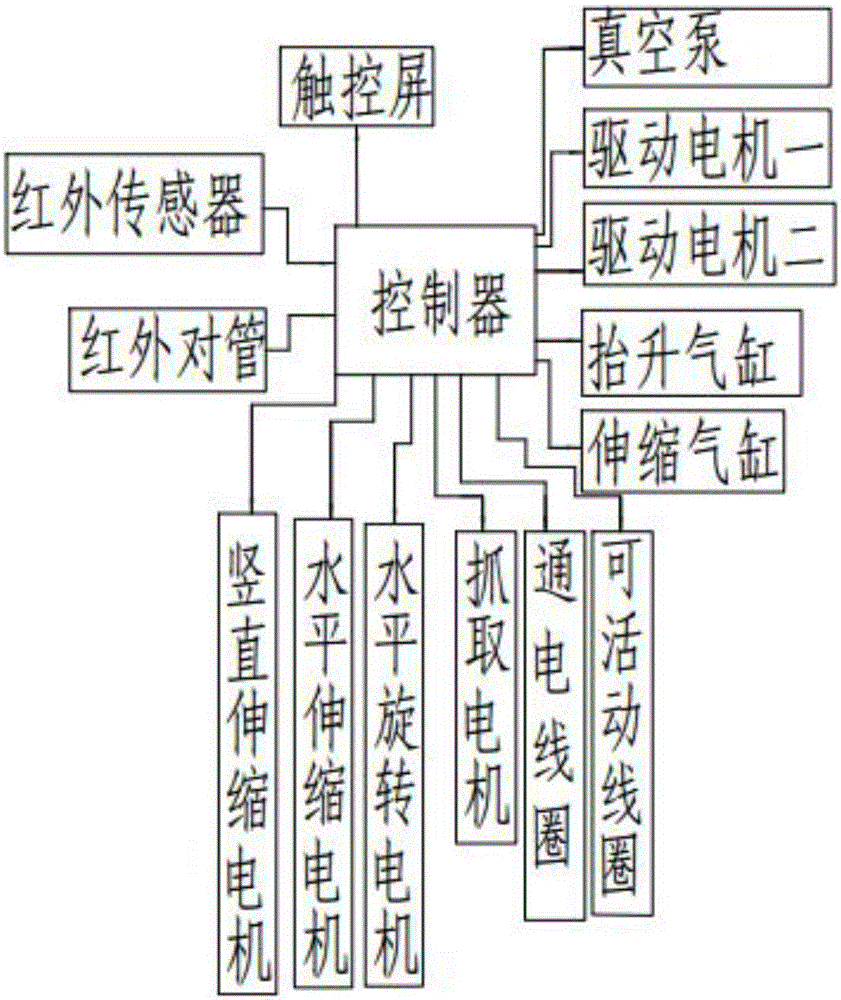

[0016] Embodiment 1: as Figure 1-Figure 4 As shown, a garbage bag fixing device for automatically packing and bag-changing garbage bins includes a guide ring 4, and an elastic vacuum adsorption ring 22 is arranged on the inside of the guide ring 4. The vacuum adsorption ring 22 can absorb and fix the garbage bag, and the vacuum adsorption ring 22 is An annular groove structure, the groove is connected with a vacuum tube, the vacuum tube is connected to a vacuum pump, and the vacuum tube is connected to the groove through a vacuum hole.

[0017] Preferably, the above-mentioned vacuum pump is connected to the control terminal of the controller through a relay, and the signal terminal of the controller is connected to the touch switch inside the top of the guide ring.

[0018] Preferably, there are three vacuum holes, which are uniformly distributed around the vacuum adsorption ring 22 .

Embodiment 2

[0019] Embodiment 2: The above-mentioned fixing device is used in a kind of automatic bag-changing garbage box, which includes a box body 1, and a garbage can 2 is arranged in the box body 1. The garbage can 2 is a barrel-shaped structure with two ends open, and its lower end A lifting mechanism for lifting the trash can 2 and a movable coil 3 are provided, a guide ring 4 and a lifting mechanism connected with the guide ring 4 are placed on the upper end, the movable coil 3 can move upward along the inner wall of the trash can 2, and a garbage cover 5 is also included , the lower side of the garbage cover 5 is provided with a energized coil 6, the energized coil 6 is facing the upper end of the garbage can 2, and the lower and upper ends of the garbage can 2 are provided with a plastic sealing mechanism, and also includes a manipulator 7, which can realize horizontal and vertical expansion and vertical expansion. Rotate and grab the garbage bag, the box body 1 of the garbage ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com