Fluorine-strengthened bioactivity mineral powder and preparation method and application thereof

A technology of bioactive minerals and mineral powders, applied in the field of oral medicine, can solve the problems of high equipment requirements, high production costs, and large loss of volatile phosphorus pentoxide, etc., and achieve the effect of rapid expression of activity and shortened hydration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

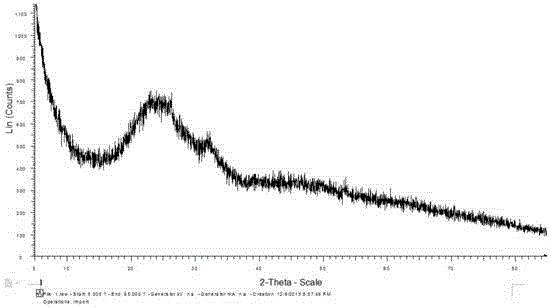

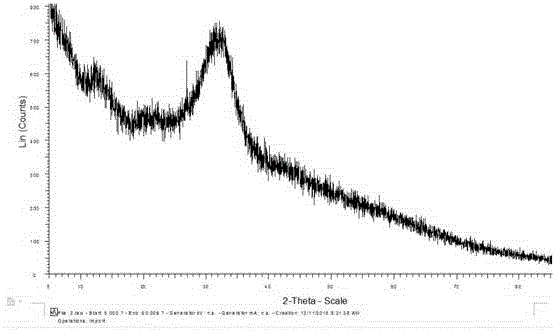

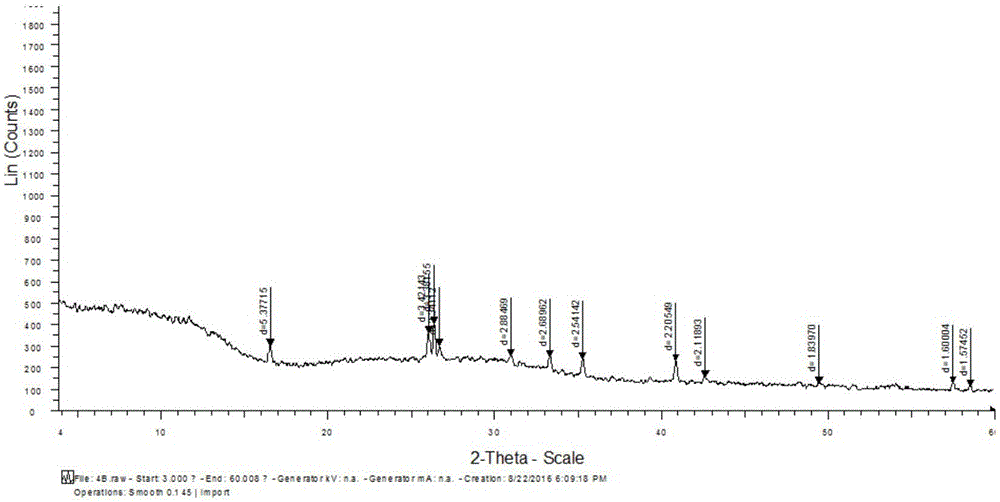

Image

Examples

Embodiment 1

[0036] Example 1 A fluorine-enhanced bioactive mineral powder material and its preparation method

[0037] 1. The composition of the mineral powder material is:

[0038] Element mass percentage SiO 2

40% CaO 25% Na 2 o

23% P 2 o 5

7% F 5%

[0039] 2. Calculation of raw materials: Weigh various raw materials according to the following proportions:

[0040] Element mass percentage SiO 2

30% CaCO 3

25% Na 2 CO 3

30% P 2 o 5

7% sodium monofluorophosphate 8%

[0041] 3. Preparation method: Fully mix the above materials with mixing equipment. After mixing, put it into the crucible equipment. During the heating process of the crucible equipment, keep it at 650°C for 30 minutes, keep it at 700°C for 30 minutes, and finally keep it at 1050°C for 2 hours. After fully homogenizing, the mineral melt is put into pure water, rapidly quenched and cooled, and dried a...

Embodiment 2

[0043] Example 2 A fluorine-enhanced bioactive mineral powder material and its preparation method

[0044] The difference between this embodiment and embodiment 1 is: increase the consumption of sodium monofluorophosphate in the raw material to be 15%, reduce SiO in the raw material 2 The dosage is 23%.

[0045] After preparing according to the method described in Example 1, the composition of the obtained mineral powder material is:

[0046] Element mass percentage SiO 2

Embodiment 3

[0047] Example 3 A fluorine-enhanced bioactive mineral powder material and its preparation method

[0048] The difference between this embodiment and embodiment 1 is: increase the amount of sodium monofluorophosphate in the raw material to 10%, reduce the amount of CaCO in the raw material 3 The dosage is 20%.

[0049] After preparing according to the method described in Example 1, the composition of the obtained mineral powder material is:

[0050] Element mass percentage SiO 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com