Method for catalytically depolymerizing lignin by using MTO (Methyltrioxorhenium) under microwave promoted condition

A technology of methyl rhenium trioxide and catalytic depolymerization, applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of organic compounds, etc., can solve the problems of consuming large external hydrogen sources, destroying benzene rings, increasing costs, etc. , to achieve high atom economy, fast reaction speed and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

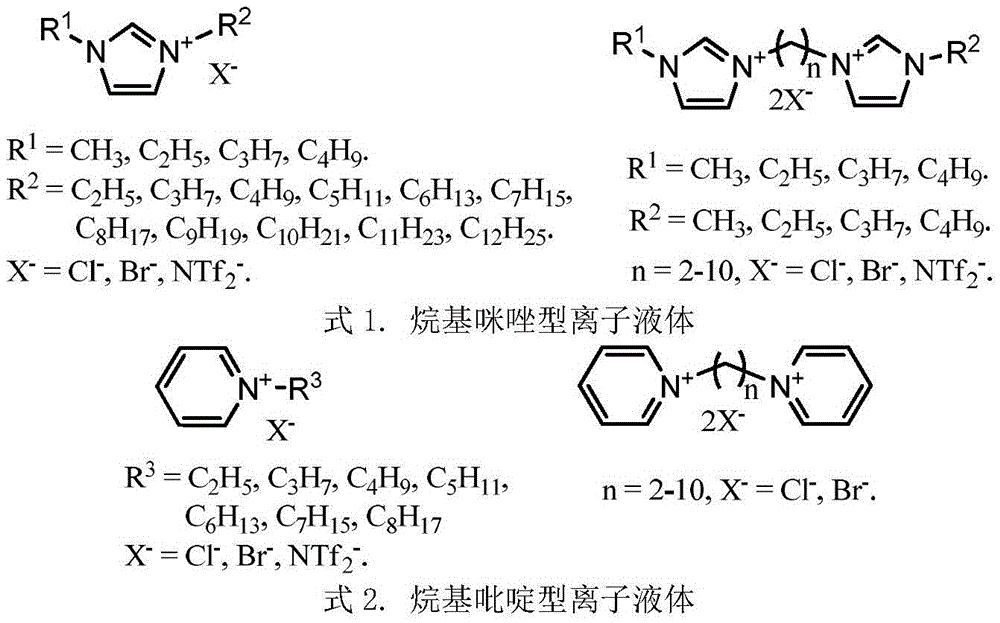

[0020] Preparation of ionic liquid solvent: refer to literature (C.P.Fredlake, J.M.Crosthwaite, D.G.Hert, S.N.U.K.Aki, J.F.Brennecke, J.Chem.Eng.Data, 2004, 49, 954.; Webb P B, Sellin M F, Kunen T E, et al.J .Am.Chem.Soc.2003,125,15577.) Prepared and purified dozens of ionic liquids with strong dissolving ability of lignin, which are used for the implementation of the patent of the present invention.

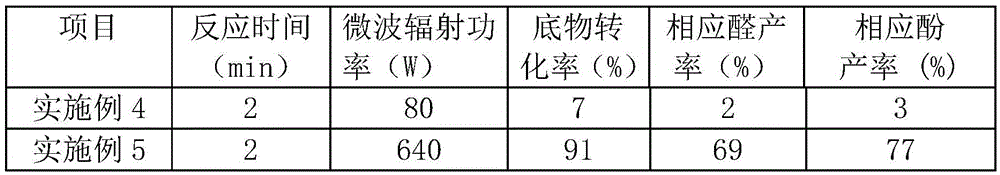

[0021] Methyl rhenium trioxide catalyzes the depolymerization of lignin model compounds and organic lignin under microwave conditions, including

[0022] Include the following steps:

[0023] ① Lignin model compound or organic lignin and catalyst are preheated and dissolved in ionic liquid at 80°C to 120°C;

[0024] ②Transfer the aforementioned mixture to a microwave reaction system and react under microwave radiation conditions. The rated power used for microwave radiation is 240W, and the reaction time is 2 minutes;

[0025] ③ after the reaction finishes, extract the reactio...

Embodiment 1

[0028] 1 gram of ionic liquid 1-butyl-3-methylimidazole bistrifluoromethylsulfonimide [C 4 MIm]NTf 2, 50 mg lignin model compound β-O-4: 2-(2-methoxyphenoxy)-1-phenylethanol, and 2.5 mg catalyst methyl rhenium trioxide were heated to 80 ℃, fully dissolved; transfer the liquid material to a microwave reaction system, and react under microwave radiation (power 240W) for 2 minutes; cool the reaction mixture to room temperature, dilute to 25 ml with a solution of acetonitrile: water 6:4 , into the liquid chromatography analysis, the conversion rate is 98%, the yield of guaiacol is 69%, and the yield of phenylacetaldehyde is 64%.

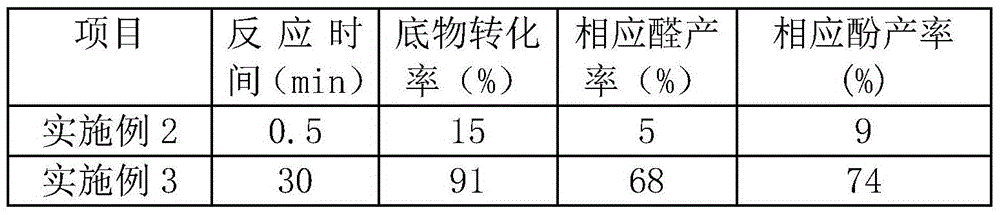

Embodiment 2-3

[0030] Other process conditions and experimental steps are the same as in Example 1, but using different reaction times, the results are shown in Table 1.

[0031] Table 1. Depolymerization of lignin model compounds under different reaction time conditions

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com