Nanometer material for non-contact printing-consumable-free laser direct printing and printing method thereof

A nanomaterial, non-contact technology, applied in the field of nanomaterials, can solve problems such as printing failure, and achieve the effects of fine graphics, good light scattering characteristics, and good coloring performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The non-contact non-printing consumables laser direct printing nanomaterials of the embodiment of the present invention are made of plastic or its composite substrate mixed with a coloring agent with a weight content of 0.052% and an average particle size of 0.85 μm and a photocatalyst titanium dioxide. Among them, the composition of titanium dioxide is TiO with micron particle size 2 Accounted for 85%, nano-sized TiO 2 Accounting for 15%; the plastic is PC, ABS, PE, PS, PET, BOPP or PVC polymer polyester material; the plastic compound is two of PC, ABS, PE, PS, PET, BOPP or PVC polymer polyester material A mixture of one or more materials.

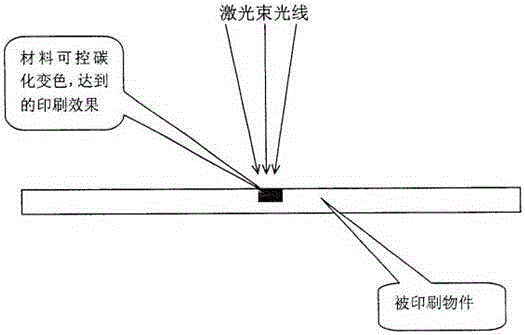

[0017] The non-contact non-printing consumables laser direct printing method of the embodiment of the present invention firstly prepares the non-contact non-printing consumables laser direct printing nanomaterials made by the above process, and then prints the graphics and texts that need to be printed on the surface of the materi...

Embodiment 2

[0019] The non-contact non-printing consumable laser direct printing nanomaterial of the embodiment of the present invention is made of plastic or its composite substrate mixed with a colorant with a weight content of 3% and an average particle size within the range of 1.05 μm and a photocatalyst titanium dioxide. In the composition of titanium dioxide, micron-sized particle size TiO 2 Accounted for 85%, nano-sized TiO 2 Accounting for 15%; the plastic is PC, ABS, PE, PS, PET, BOPP or PVC polymer polyester material; the plastic compound is two of PC, ABS, PE, PS, PET, BOPP or PVC polymer polyester material A mixture of one or more materials.

[0020] The non-contact non-printing consumables laser direct printing method of the embodiment of the present invention firstly prepares the non-contact non-printing consumables laser direct printing nanomaterials made by the above process, and then prints the graphics and texts that need to be printed on the surface of the material In...

Embodiment 3

[0022] The non-contact non-printing consumable laser direct printing nanomaterial of the embodiment of the present invention is made of plastic or its composite substrate mixed with a colorant with a weight content of 6% and an average particle size within the range of 2.05 μm and a photocatalyst titanium dioxide. Among them, the composition of titanium dioxide, micron-sized particle size TiO 2 Accounted for 95%, nano-sized TiO 2 5%; the plastic is PC, ABS, PE, PS, PET, BOPP or PVC polymer polyester material; the plastic compound is two of PC, ABS, PE, PS, PET, BOPP or PVC polymer polyester material A mixture of one or more materials.

[0023] The non-contact non-printing consumables laser direct printing method of the embodiment of the present invention firstly prepares the non-contact non-printing consumables laser direct printing nanomaterials made by the above process, and then prints the graphics and texts that need to be printed on the surface of the material Input the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com