A kind of thermal transfer label surface paper and production method

A thermal transfer and labeling technology, which is applied in the direction of paper, papermaking, papermaking machines, etc., can solve the problems affecting paper durability, scratch resistance, smear resistance, corrosion resistance and high temperature resistance, detachment, displacement, warping, label paper surface Reflection and other issues, to achieve the effect of improving light scattering performance, eliminating specular reflection, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Get 80 parts of ground calcium carbonate, 20 parts of fumed nano-silica, 10 parts of PVA, 10 parts of EVA, and mix them evenly to obtain the coating coated by the receiving layer; the solid content of the coating is 55%, and the viscosity is controlled at 1000cps; the above-mentioned coating is used for coating On base paper, the coating weight is 10g / m 2 the receiving layer.

Embodiment 2

[0054] a. Coating of heat-resistant layer: Take 70 parts of calcium carbonate, 30 parts of china clay, and 17 parts of styrene-butadiene latex, and mix them evenly to obtain the coating for the bottom coating. The solid content of the coating is 61%, and the viscosity is controlled at 800cps; the above-mentioned coating is used Coating on base paper to form a coating weight of 8g / m 2 bottom layer.

[0055] b. Receiving layer coating: the total of white pigment particles is 100 unit weights, and the proportions of other coating components are relative to the 100 unit weights, and the chemicals used are all calculated on an absolute dry basis; take 90 parts of calcium carbonate, Gas-phase nano-silica, 10 parts of styrene-butadiene latex, 5 parts of PVA, 5 parts of EVA are mixed uniformly to obtain the coating coated by the receiving layer. The solid content of the coating is 60%, and the viscosity is controlled at 1000cps. Using the above-mentioned coating in step a Coating on ...

Embodiment 3

[0057] a. Coating of heat-resistant layer: Take 80 parts of ground calcium carbonate, 20 parts of China clay, and 20 parts of styrene-butadiene latex, and mix them evenly to obtain a primer. The solid content of the coating is 63%, and the viscosity is controlled at 800cps; use the above-mentioned coating on the base paper Coating to form a heat-resistant layer with a coating amount of 12 g / m2.

[0058] B, receiving layer coating: get 85 parts of grinding calcium carbonate, 15 parts of gas-phase nano silicon dioxide, 15 parts of styrene-butadiene latex and 5 parts of EVA, mix uniformly to obtain surface coating, the solid content of coating is 60%, and viscosity is controlled at 1000cps, use the above-mentioned coating to coat on the heat-resistant layer in step a, forming a coating amount of 8g / m 2 the receiving layer.

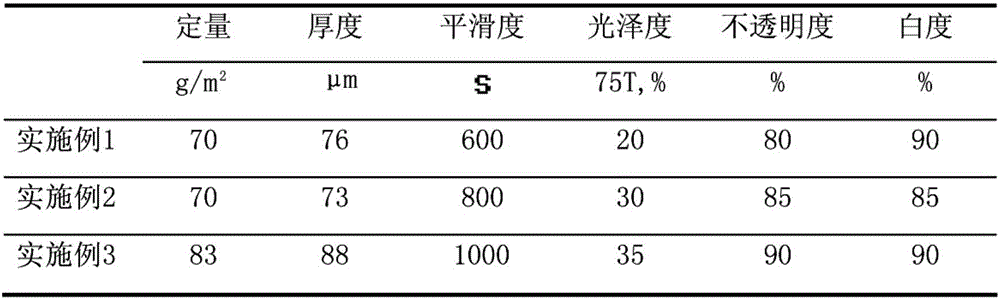

[0059] Table 1 Physical indicators of different implementation cases

[0060]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com