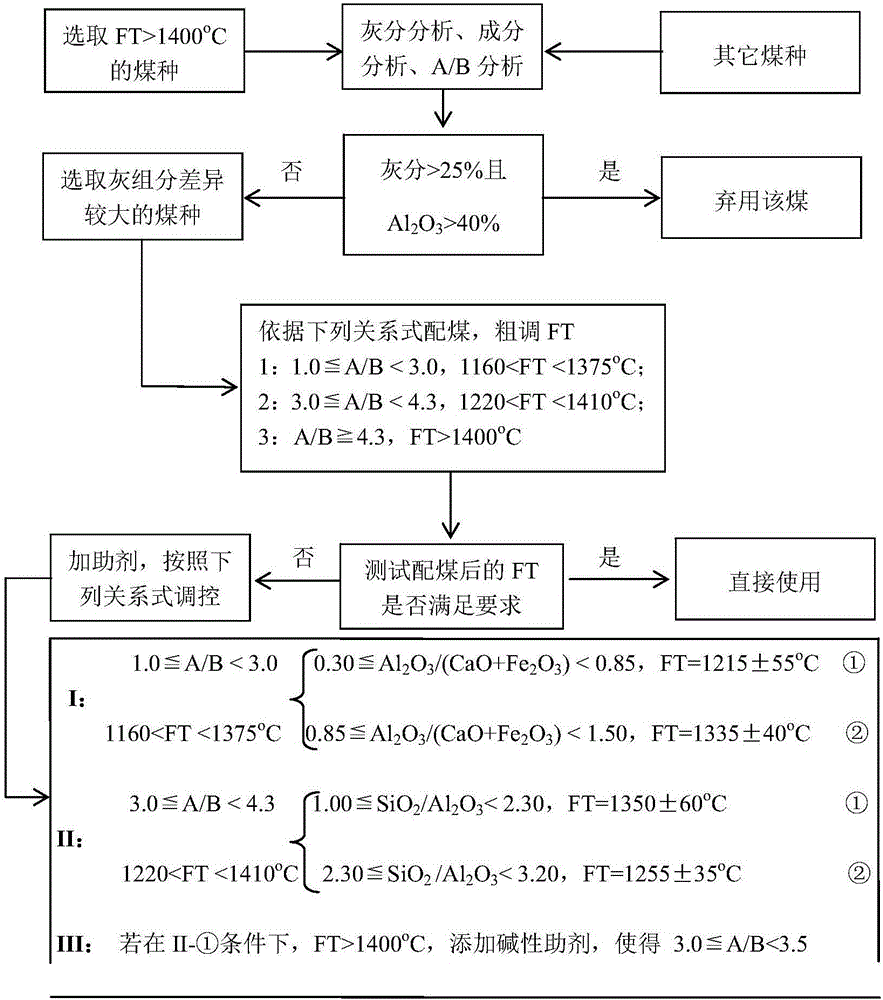

Method for regulating and controlling flowing temperature of high-melting-point coal ash

A technology with flow temperature and high melting point, applied in gasification process, petroleum industry, manufacture of combustible gas, etc., can solve the problems of reducing FT of coal ash, reducing calorific value, insufficient representation, etc., to reduce the amount of addition and ensure the calorific value. , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

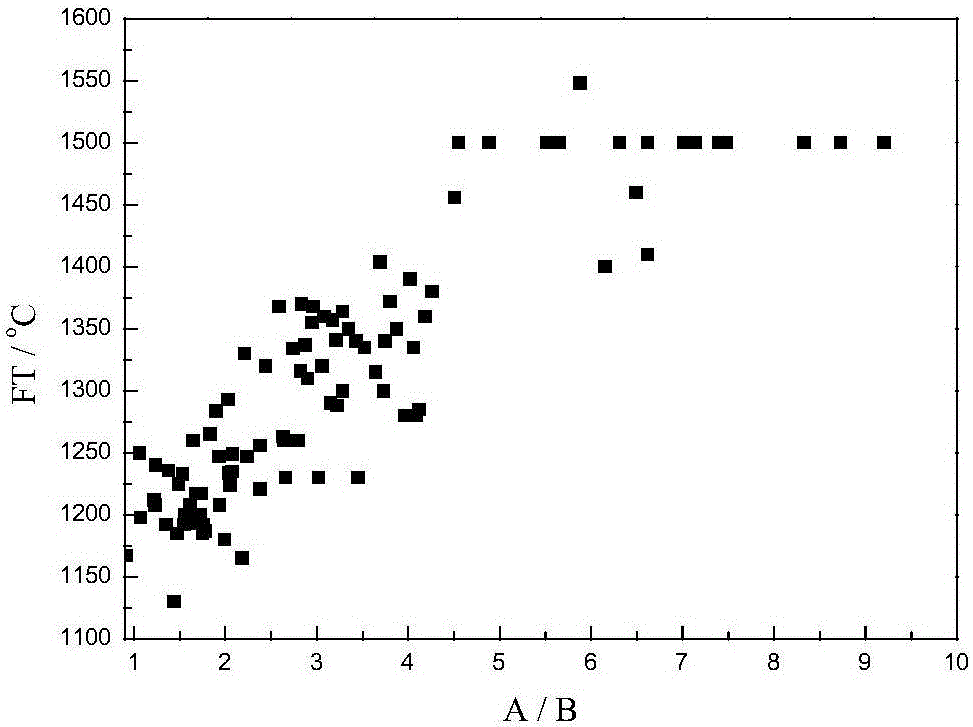

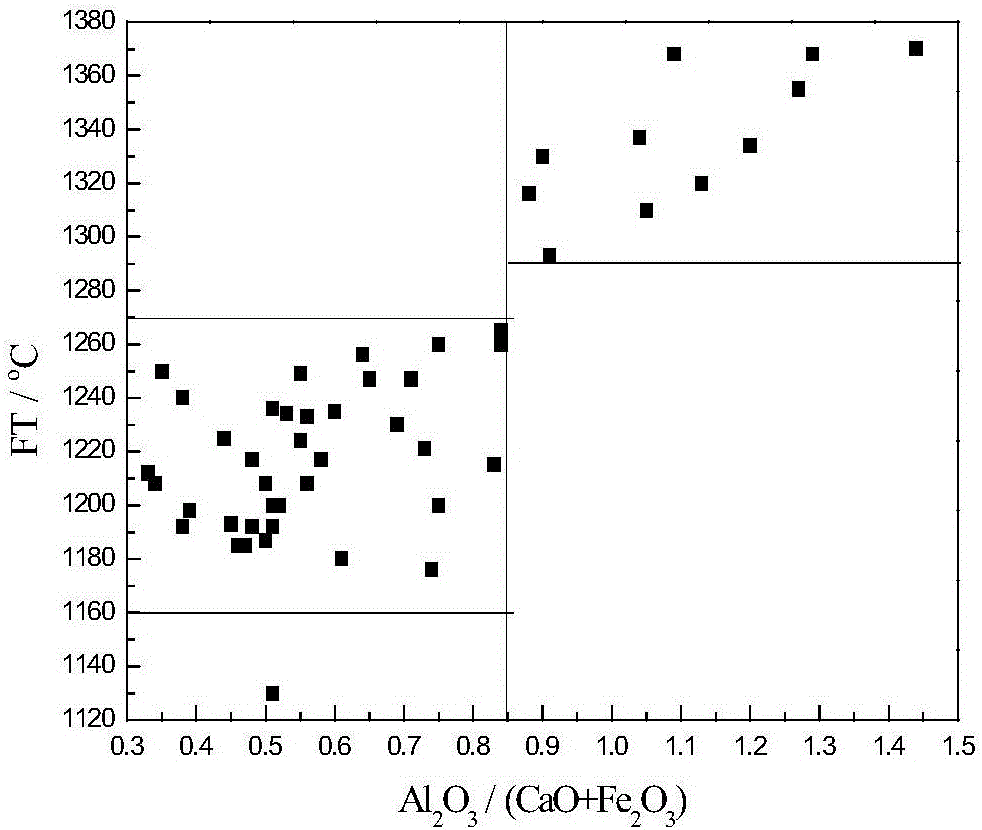

Method used

Image

Examples

Embodiment 1

[0044] (1) Select typical Jincheng anthracite (JC) with high melting point and Xiangyang coal (XY) with low melting point to conduct industrial analysis and analysis of various components in coal ash to analyze whether the ash content is higher than 25%, Al 2 o 3 Whether the content is higher than 40%. According to industrial analysis, the ash content of the two coals is less than 25%, Al 2 o 3 The content is less than 40%.

[0045] (2) Calculate the A / B of different proportions according to the ash analysis results, and the results are shown in Table 1.

[0046] Table 1 Analysis of the mixed coal ash of Xiangyang coal and Jincheng anthracite

[0047] project SiO 2

A1 2 o 3

Fe 2 o 3

CaO MgO TiO 2

A / B JC 47.00 33.55 7.99 5.16 1.60 0.85 5.52 10%XY 45.75 31.04 8.85 7.00 1.71 0.84 4.42 20%XY 44.43 30.45 9.76 8.94 1.82 0.83 3.69 30%XY 43.05 28.79 10.7 10.97 1.94 0.82 3.08 40%XY 41....

Embodiment 2

[0061] (1) Select typical high melting point Jincheng anthracite (JC) and Shenhua coal direct liquefaction residue (DCLR) for industrial analysis and analysis of various components in coal ash to analyze whether the ash content is higher than 25%, Al 2 o 3 Whether the content is higher than 40%. The ash content of both samples was less than 25% by industrial analysis.

[0062] (2) Calculate the A / B of different proportions according to the ash analysis results, and the results are shown in Table 3.

[0063] Table 3 Analysis of mixed coal ash of Shenhua coal direct liquefaction residue and Jincheng anthracite

[0064] project SiO 2

A1 2 o 3

Fe 2 o 3

CaO MgO TiO 2

A / B JC 47.00 33.55 7.99 5.16 1.60 0.85 5.52 10%DCLR 44.86 31.54 9.47 6.00 1.55 0.95 4.55 20%DCLR 42.64 29.45 11.00 6.87 1.49 1.05 3.78 30%DCLR 40.33 27.27 12.60 7.77 1.43 1.16 3.15 40%DCLR 37.93 25.02 14.25 8.71 1.37...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com