Method for quickly and efficiently regulating and controlling flowing temperature of coal ash

A technology of flow temperature and coal ash, applied in the field of coal gasification, can solve the problems of black box operation, large difference in component content, poor adaptability, etc., and achieve the effect of good applicability, wide range of raw materials, and efficient regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

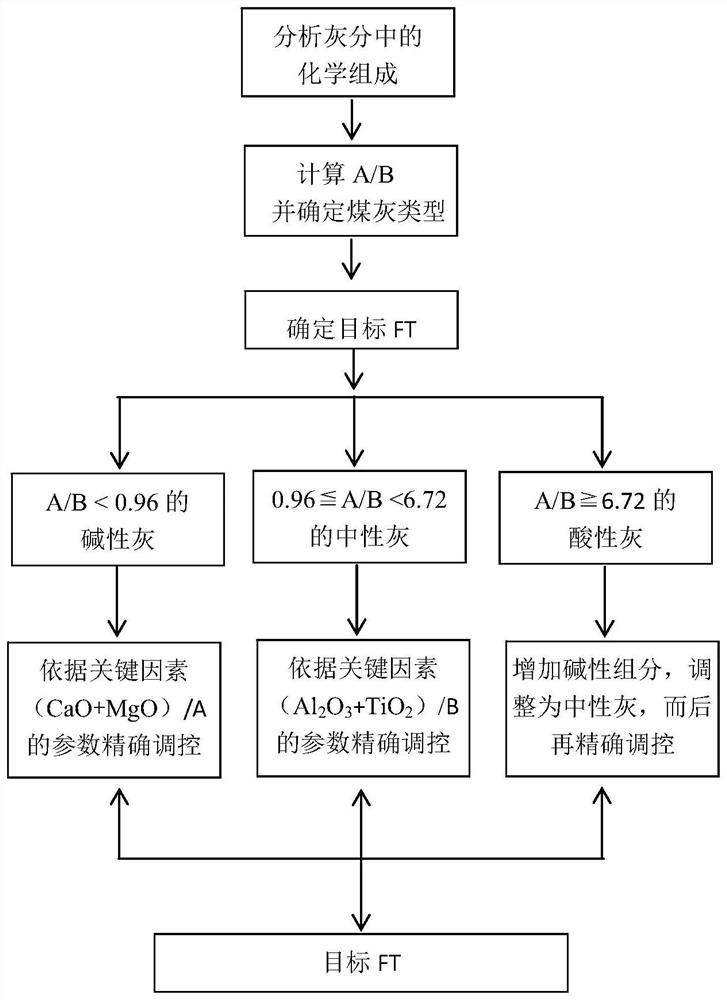

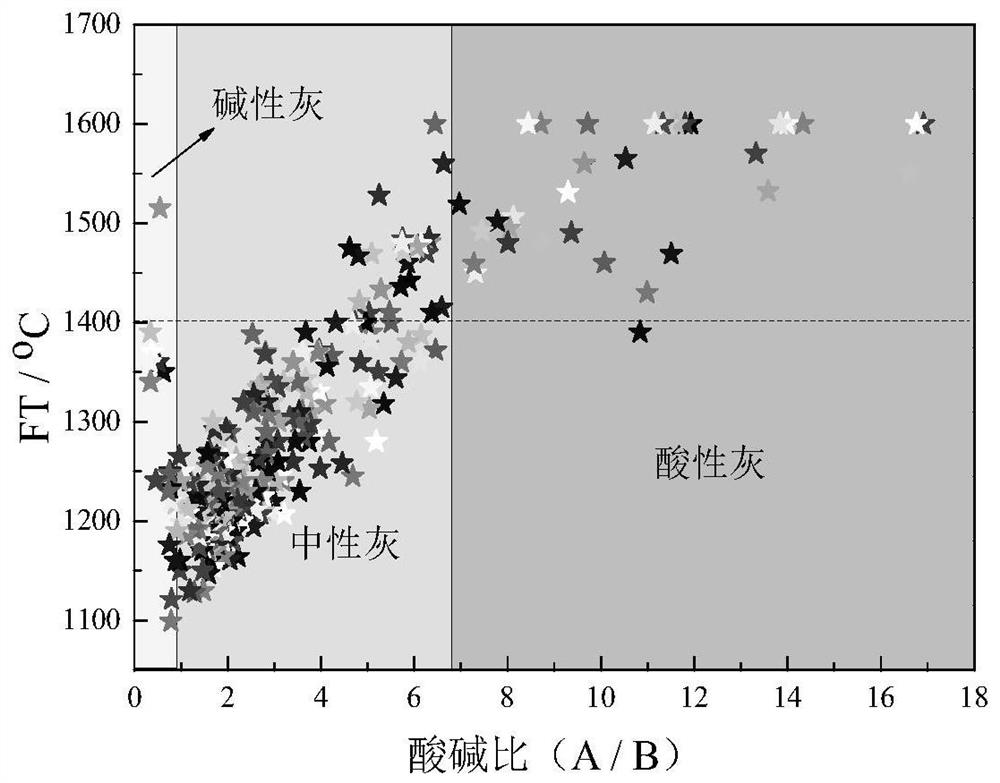

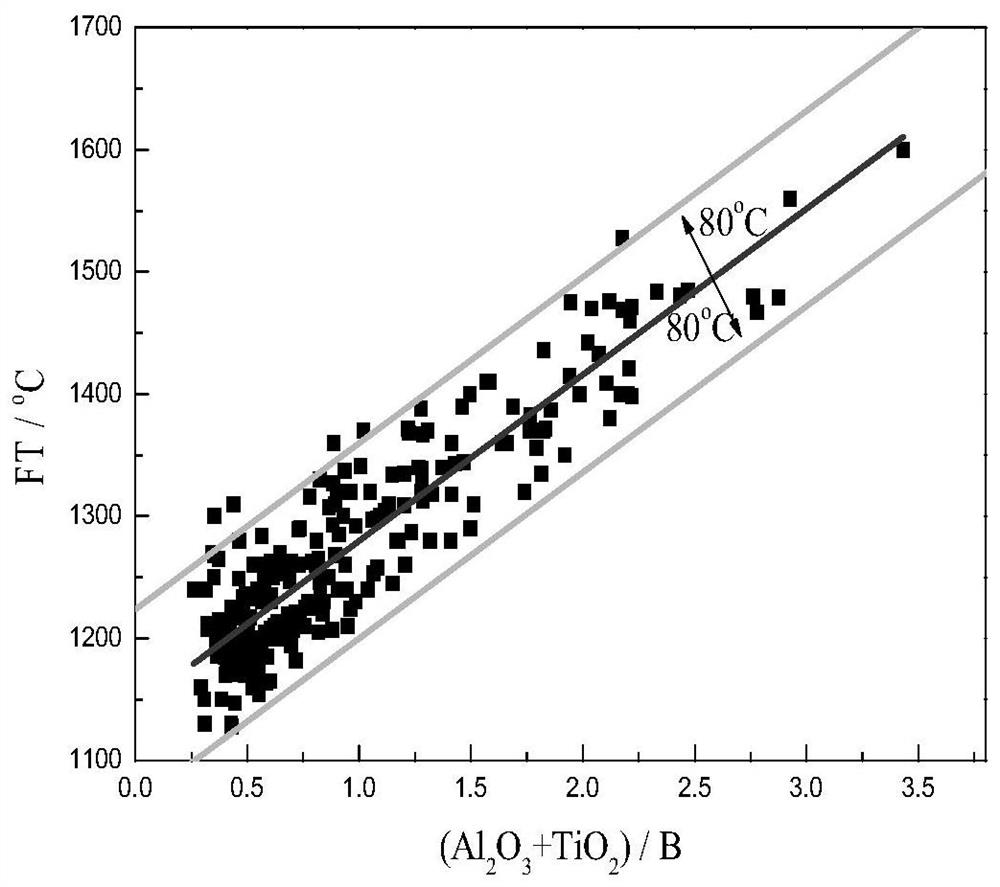

Method used

Image

Examples

Embodiment 1

[0039] (1) Select Jincheng anthracite (JC) and corn stover (YM) with obvious differences in ash composition for illustration. First, JC and YM were ashed, and the chemical composition of each ash sample was analyzed.

[0040] (2) Calculate the A / B of the ash sample according to the analysis results of the chemical composition in the ash, see Table 1 for the results.

[0041] Table 1 Chemical composition analysis of JC ash and YM ash

[0042] project SiO 2

A1 2 o 3

Fe 2 o 3

CaO MgO TiO 2

K 2 o

Na 2 o

A / B JC 47.00 33.55 7.99 5.16 1.60 0.85 0.38 0.46 5.22 X Y 53.37 2.94 1.46 7.17 4.06 0.16 19.61 0.86 1.70

[0043] (3) It can be seen from Table 1 that the two kinds of ash belong to neutral gray samples, and the key factor 1 can be used to regulate FT. Table 2 shows the FT of JC ash and YM ash calculated by relational formula 2 and the measured results. It can be seen from Table 2 that the ca...

Embodiment 2

[0050] (1) Select Jincheng anthracite (JC) and Shenhua liquefaction residue (DCLR) with obvious differences in ash composition for illustration. First, the JC and DCLR are ashed, and the chemical composition of each ash sample is analyzed.

[0051] (2) Calculate the A / B of the ash sample according to the analysis results of the chemical composition in the ash, see Table 4 for the results.

[0052] Table 4 Chemical composition analysis of JC ash and DCLR ash

[0053] project SiO 2

A1 2 o 3

Fe 2 o 3

CaO MgO TiO 2

K 2 o

Na 2 o

A / B JC 47.00 33.55 7.99 5.16 1.60 0.85 0.38 0.46 5.22 X Y 21.3 9.37 25.74 15.23 0.95 2.05 0.20 1.58 0.75

[0054] (5) It can be seen from Table 4 that JC ash belongs to neutral gray samples, while DCLR ash belongs to alkaline ash samples, so the FT is calculated by using relational formula 2 and relational formula 1 respectively. The calculated FT of JC gray and DCLR g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com