A sizing machine with dyeing and hairiness detection functions and a method for manufacturing sizing

A sizing and detection device technology, applied in textiles and papermaking, yarn, singeing and other directions, can solve the problems of lack of dyeing and hairiness detection functions, low work efficiency, complex equipment, etc., to improve the effect and cost of nano-spinning Low, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

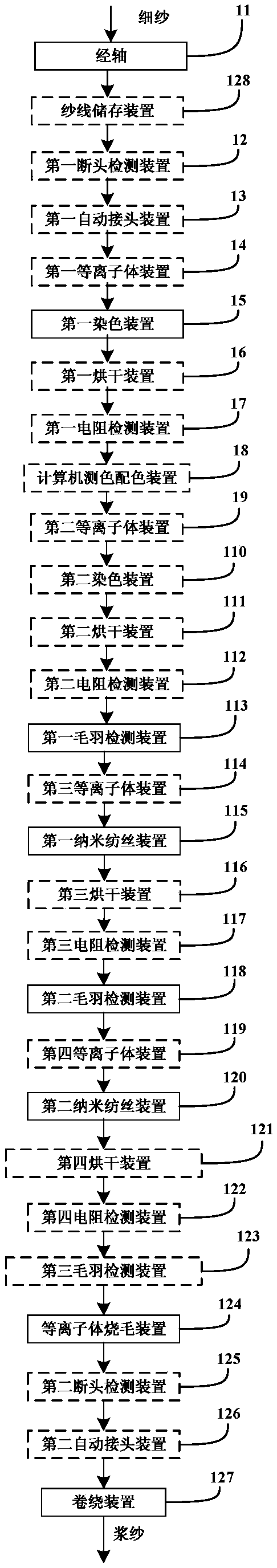

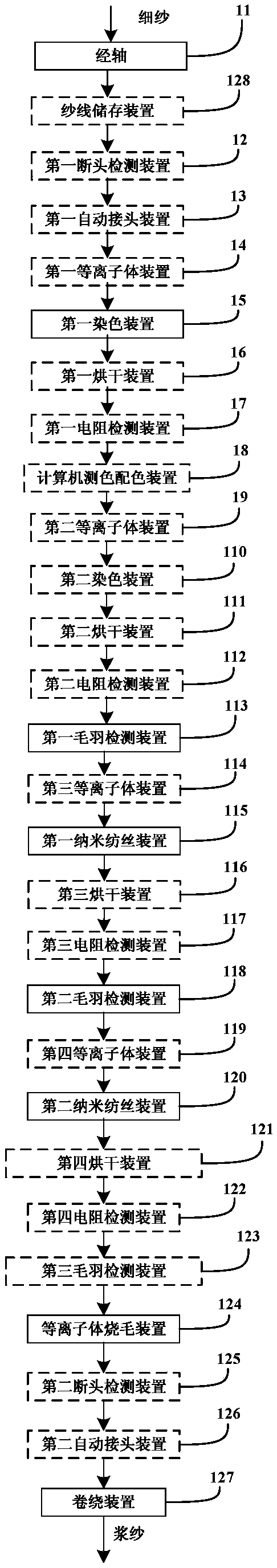

[0043] Such as figure 1 As shown, this specific embodiment discloses a sizing machine with dyeing and hairiness detection functions, including a warp beam 11, a first dyeing device 15, a first hairiness detection device 113, a first nano-spinning device 115, a second Hairiness detection device 118, second nano-spinning device 120, plasma singeing device 124 and winding device 127; spun yarn enters first dyeing device 15 through warp beam 11 to carry out spray dyeing, then carries out hairiness by first hairiness detection device 113 Detect, and set the parameter of the first nano-spinning device 115 according to the hairiness detection result, then spray nanofibers by the first nano-spinning device 115, then carry out hairiness detection by the second hairiness detection device 123, the second hairiness detection device 123 according to The hairiness detection result adjusts the parameter of the first nano-spinning device 115 and judges whether to activate the second nano-spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com