Installation process of sinking pipe for offshore water intake and discharge in power plant

An installation process, water intake and drainage technology, applied in water supply installations, drinking water installations, caisson tanks, etc., can solve the problems of many immersed tube sections, high precision control requirements for immersed tubes, and low buoyancy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with accompanying drawing.

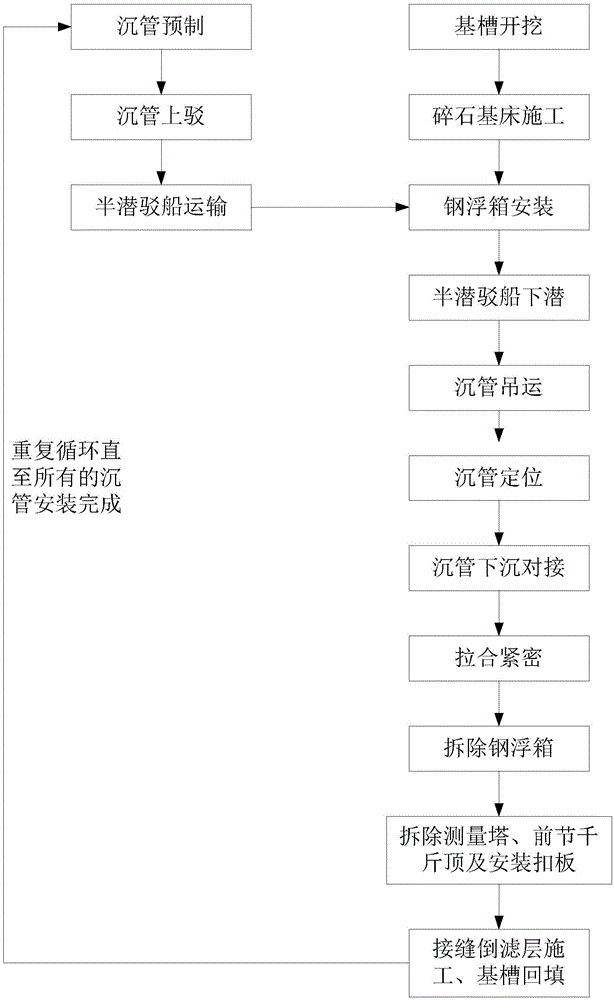

[0057] see Figure 1 to Figure 13 , the present invention is an installation process of immersed tubes for water intake and drainage in power plants, comprising the following steps: immersed tube prefabrication, immersed tube barge, semi-submerged barge transportation, steel buoyant tank installation, semi-submersible barge submerged, immersed tube hoisting, sinking Tube positioning, sinking and docking of immersed tubes, tight pulling and closing, removal of steel buoyancy tanks, removal of measuring towers, front section jacks and installation of gussets.

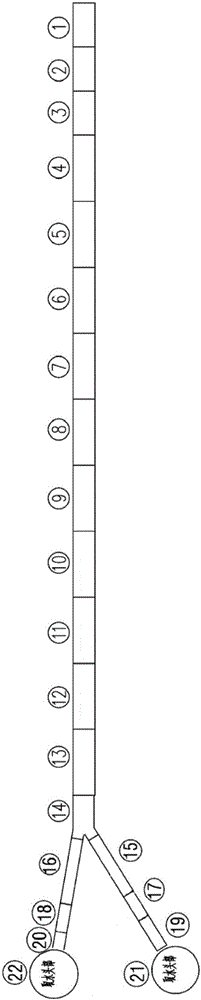

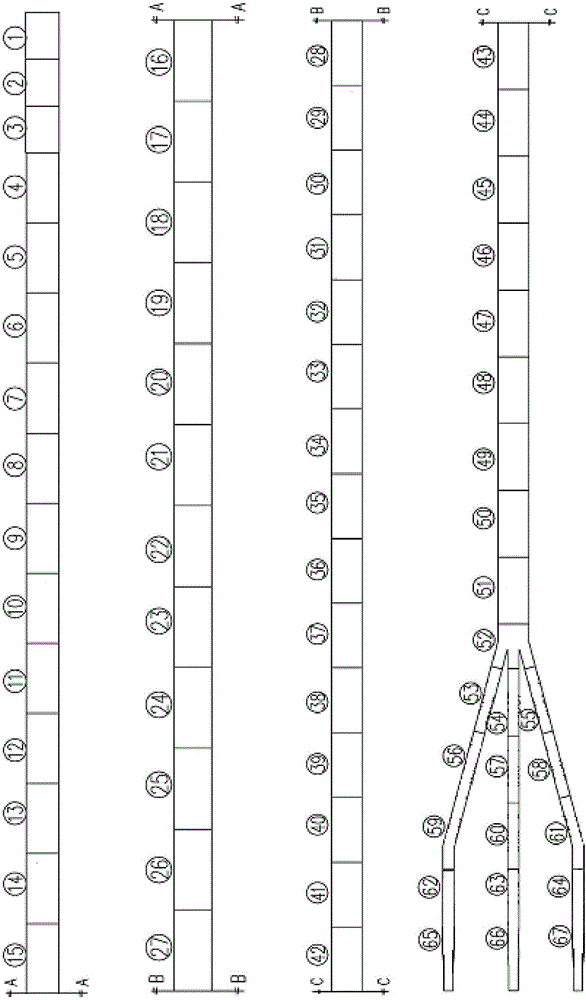

[0058] During the prefabrication steps of immersed tubes, 20 sections of water intake immersed tubes, two water intake head caissons, 64 sections of drainage immersed tubes and three outfall head immersed tubes are prefabricated at the prefabrication yard wharf; The number of prefabricated parts is compiled from small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com