Hot air gun

A technology of a hot air gun and a fan, applied in the field of hot air guns, can solve the problems of limited use of the hot air gun, adjusting the shape of the hot air gun, etc., and achieve the effects of improving the convenience of use, maintaining the effectiveness, and ensuring the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

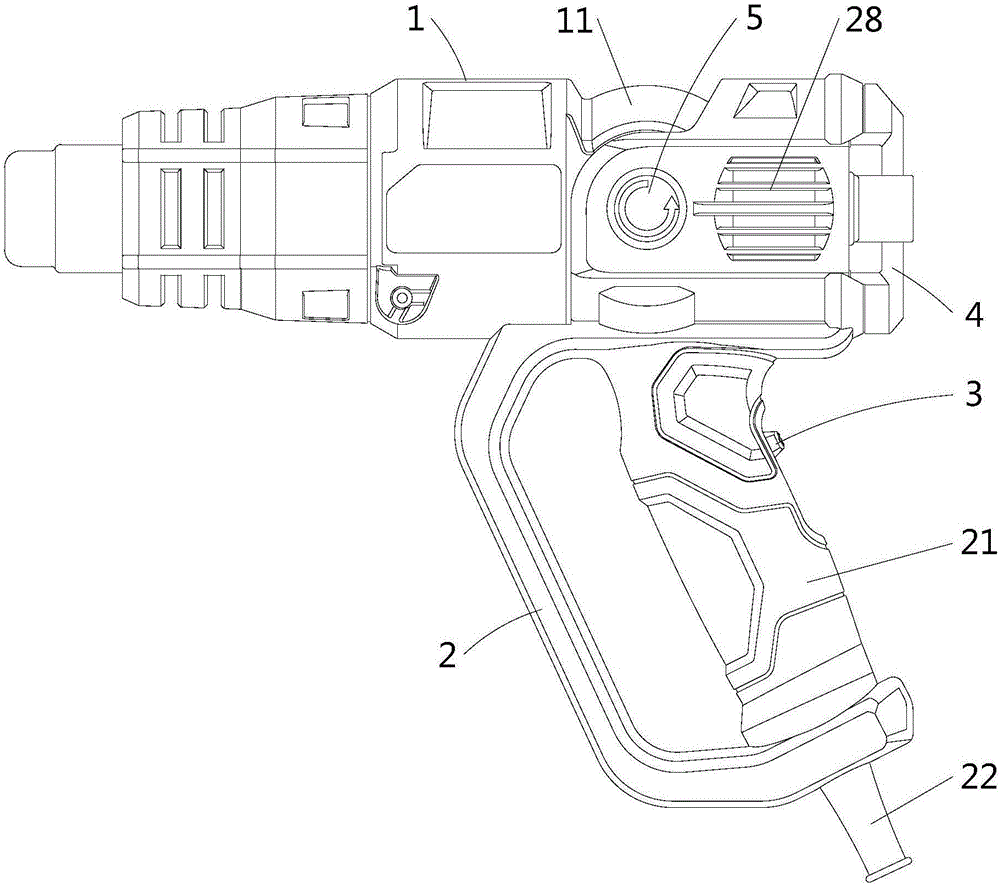

[0037] Such as figure 1 , 2 As shown, the heat gun provided by Embodiment 1 of the present invention includes a machine head and a fuselage. body 2, a switch mechanism 3 and a control mechanism 4 are arranged on the fuselage shell. The nose shell 1 and the fuselage shell 2 are rotatably connected together, and a locking mechanism 5 for keeping the nose and the fuselage relatively fixed is arranged between the nose shell 1 and the fuselage shell 2 .

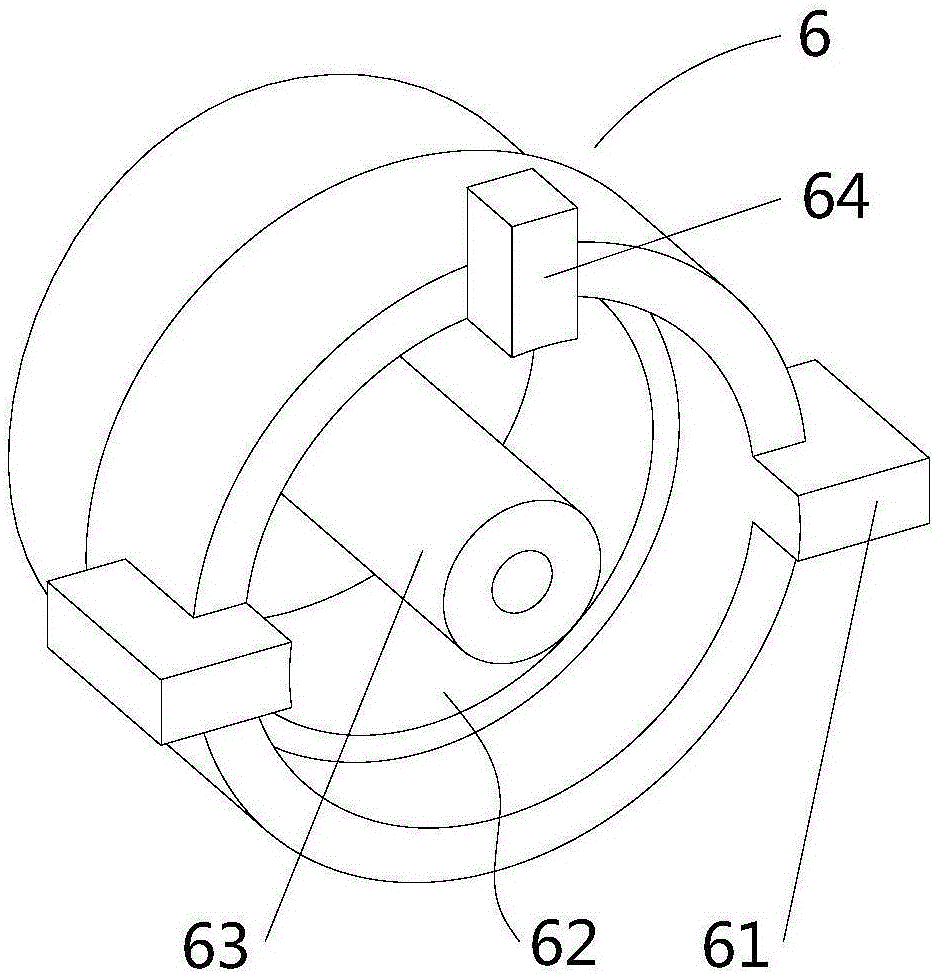

[0038] The locking mechanism 5 includes such as image 3 As shown in the lock button 6, the lock button 6 is cylindrical, and two lock blocks 61 are arranged on the circumferential side wall of the lock button. The two lock blocks 61 are located on the same radial direction and arranged symmetrically. The concave hole 62 is opened, and the bottom wall of the concave hole 62 is provided with a protruding positioning column 63 . In order to prevent wrong assembly, a leg 64 is also provided on the circumferential side wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com