Non-weld-connection cooling tower heat-radiating tube

A technology for cooling towers without welds, applied to tubular components, heat exchange equipment, heat exchanger shells, etc., can solve the problems of labor and consumables, large space occupation, and a large number of solder joints, etc., to achieve small footprint and reduce size, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

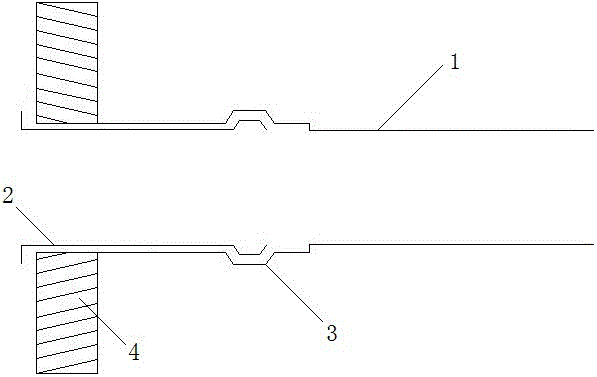

[0022] Such as figure 2 As shown, there is no welding seam to connect the heat dissipation pipe of the cooling tower, and its structure includes a straight pipe 1, a stainless steel sleeve 2, a cashew nut-shaped protrusion 3, and a tube plate 4; A cashew nut-shaped protrusion 3 is provided at 30 mm, and the stainless steel casing 2 is connected with the straight pipe 1 through the interface on the tube plate 4 .

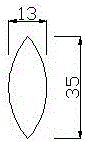

[0023] Such as figure 1 As shown, the straight pipe 1 has a wall thickness of 0.6 mm, a width of 13 mm, and a height of 35 mm, and its section is olive-shaped.

[0024] The flared mouth is 30 mm long, 14 mm wide, and 36.5 mm high, and its section is olive-shaped.

[0025] The specification of the stainless steel sleeve 2 is 13 mm×35 mm×30 mm, and the top of the stainless steel sleeve 2 is provided with a protrusion.

[0026] The cashew-shaped protrusion 3 is 14 mm long, with an inner diameter of 35.2 mm and an outer diameter of 36.2 mm.

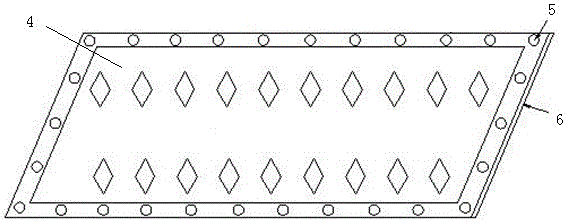

[0027] Such as image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com