Automatic detection device and method for underwater concrete casting interface

A technology of underwater concrete and detection devices, which is applied in the direction of measuring devices, lubrication indicator devices, engine components, etc., can solve the problems of manual detection that is difficult to achieve continuous detection, supervisors cannot monitor remotely, and key data cannot be transmitted in time. Compact structure, small footprint and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

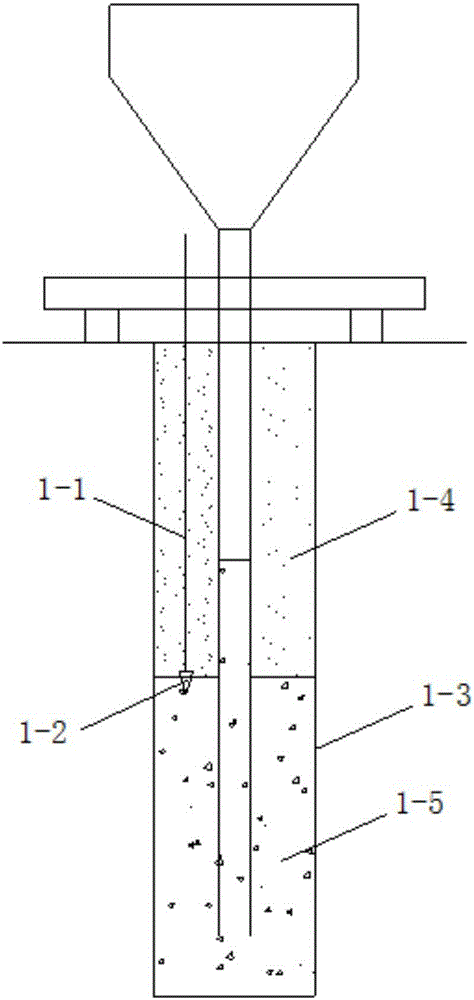

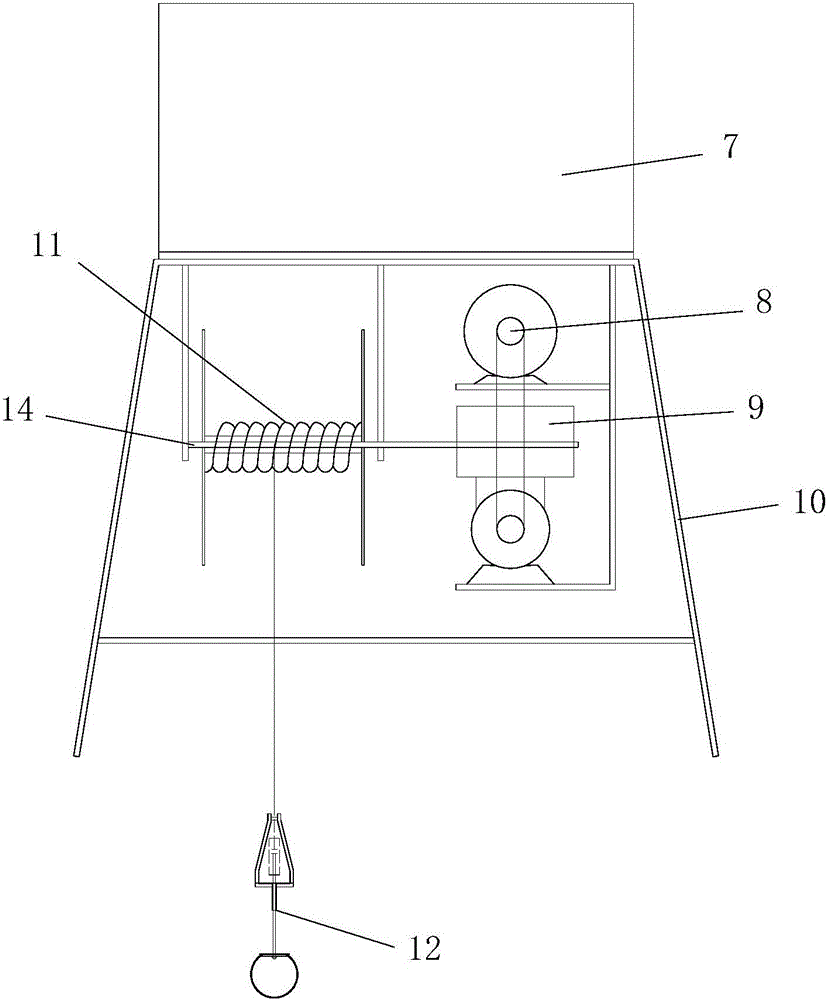

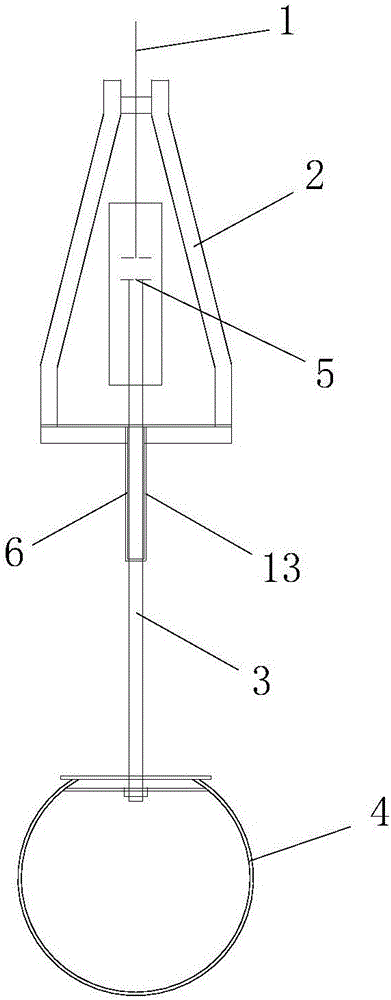

[0049] Such as figure 2 , image 3 An underwater concrete pouring interface automatic detection device shown includes a probe 12 for detecting the interface between the mud and concrete in the concrete pouring cavity, a lifting mechanism for lifting the probe 12 up and down, a control device connected to the probe 12 and A lifting height detection device for detecting the lifting height of the probe 12, the lifting height detection device is connected to the control device, the concrete pouring cavity is a constructed hole 1-3 or a groove; the probe 12 includes a hanger 2 and the counterweight 4 installed directly below the hanger 2, the bulk density of the counterweight 4 is the same as that of the concrete poured in the concrete pouring cavity; the upper part of the counterweight 4 is equipped with a vertical The connecting rod 3 arranged, the guide sleeve 13 coaxially sleeved on the connecting rod 3 is installed below the hanger 2, and the bottom of the hanger 2 has a thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com