Measuring method for novel cut stem backfilling rate

A measurement method and cut-stem technology, which is applied in the field of detection of new-type cut-stem backfill rate, can solve the problems of time-consuming and labor-intensive, inability to provide data support for product production control, and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be further described below in conjunction with specific embodiments, but it should not be construed as a limitation on the technical solution.

[0015] 1. Linear regression model building

[0016] (1) Sample preparation: Weigh 10g blank cut stems, measure its moisture x, backfill with the prepared backfill solution, then weigh the weight M and moisture X of the new cut stems after backfilling, and calculate the backfill rate value Y= (M×(1-X)-10×(1-x))×100% / M×(1-X); After backfilling, the sample is required to have multiple gradient backfill rates, in order to improve the fitting accuracy of the linear regression model , set multiple samples, that is, the backfill rate of at least five gradients;

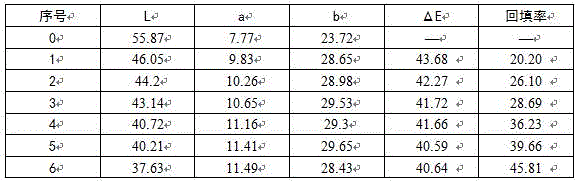

[0017] (2) Linear regression: place the backfilled new cut stems in a constant temperature and humidity chamber with a temperature of (22±1)°C and a relative humidity of (60±2)% for 24 hours; weigh 3-5g of the sample in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com