Fagopyrum tataricum noodles and making method thereof

A tartary buckwheat and noodle technology, applied in the direction of food science, etc., can solve the problems of poor quality and low nutrient element content of tartary buckwheat noodles, and achieve the effect of rich nutrition, delicate taste and rich functional substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

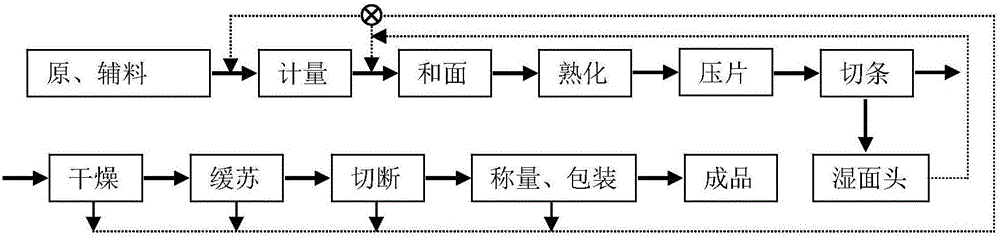

Method used

Image

Examples

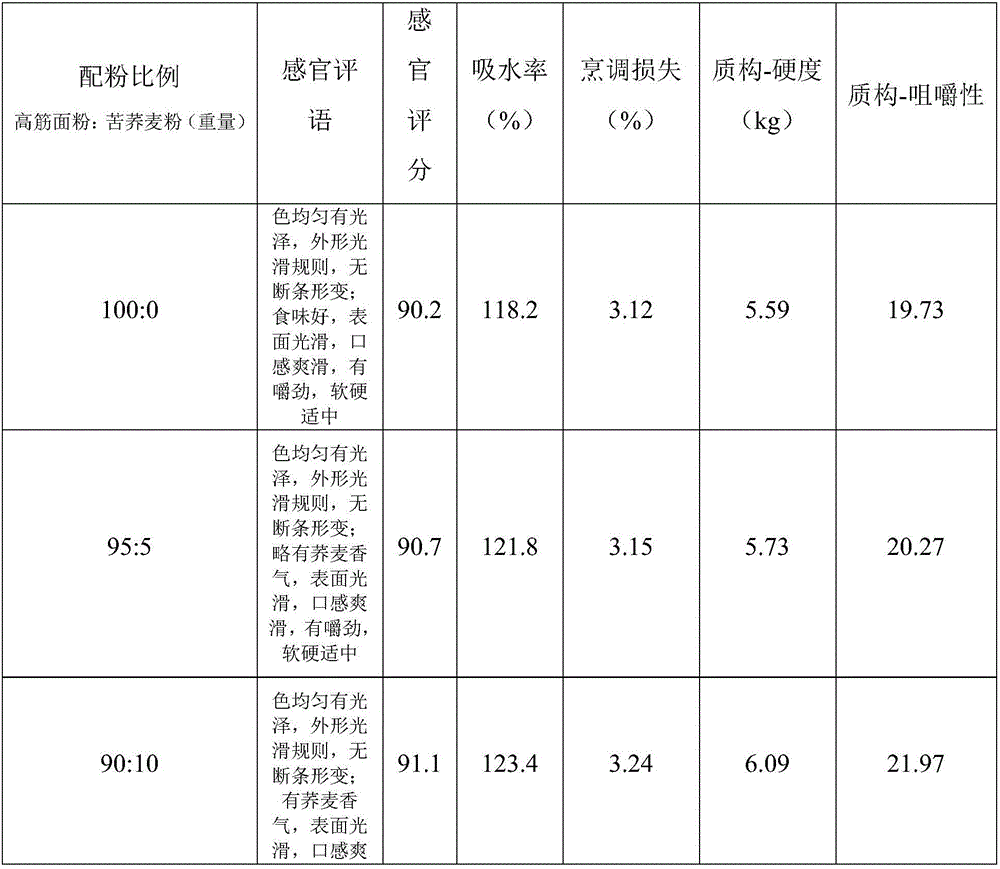

Embodiment 1

[0047] A tartary buckwheat noodle comprises the following raw materials: tartary buckwheat flour, high-gluten flour, salt and edible alkali. The weight ratio of tartary buckwheat flour and high-gluten flour is 5:95, the weight of salt is 1% of the total weight of tartary buckwheat flour and high-gluten flour, and the weight of edible alkali is 0.1% of the total weight of tartary buckwheat flour and high-gluten flour.

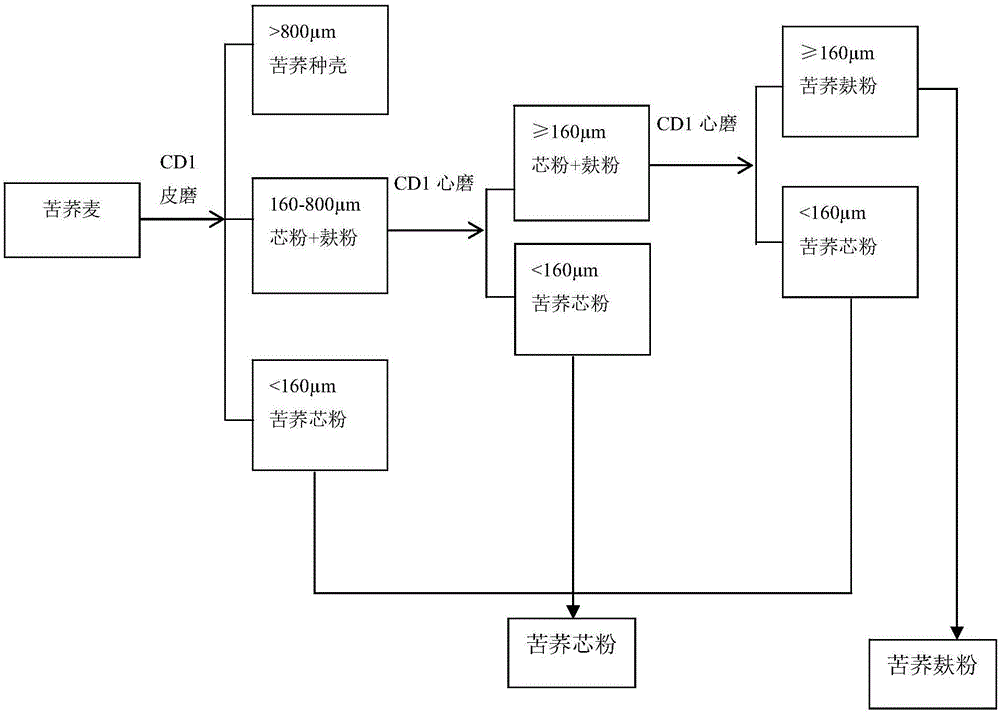

[0048] Such as figure 1 Shown, the tartary buckwheat flour preparation method of the present embodiment comprises the steps:

[0049] 1) Select tartary buckwheat varieties with plump grains and high flavonoid content as the raw material of tartary buckwheat, remove impurities and grains of diseases and insects in the raw material, grind once with CD1 skin and twice with heart, and grind tartary buckwheat seed coat, bitter buckwheat Buckwheat core powder and buckwheat bran powder are separated. Specifically, the bitter buckwheat raw material is processed once by...

Embodiment 2

[0054] A tartary buckwheat noodle comprises the following raw materials: tartary buckwheat flour, high-gluten flour, salt and edible alkali. The weight ratio of tartary buckwheat flour and high-gluten flour is 10:90, the weight of salt is 1% of the total weight of tartary buckwheat flour and high-gluten flour, and the weight of edible alkali is 0.1% of the total weight of tartary buckwheat flour and high-gluten flour.

[0055] Such as figure 1 Shown, the tartary buckwheat flour preparation method of the present embodiment comprises the steps:

[0056] 1) Select tartary buckwheat varieties with plump grains and high flavonoid content as the raw material of tartary buckwheat, remove impurities and grains of diseases and insects in the raw material, grind once with CD1 skin and twice with heart, and grind tartary buckwheat seed coat, bitter buckwheat Buckwheat core powder and buckwheat bran powder are separated. Specifically, the raw material of tartary buckwheat is processed once...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com