Multifunctional colloidal sol stirring device

A stirring device and a multi-functional technology, applied in the field of multi-functional sol stirring devices, can solve the problems of rapid damage of the rotating shaft, inconvenient feeding, uneven stirring, etc., and achieve the effects of improving the sol effect, convenient feeding and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

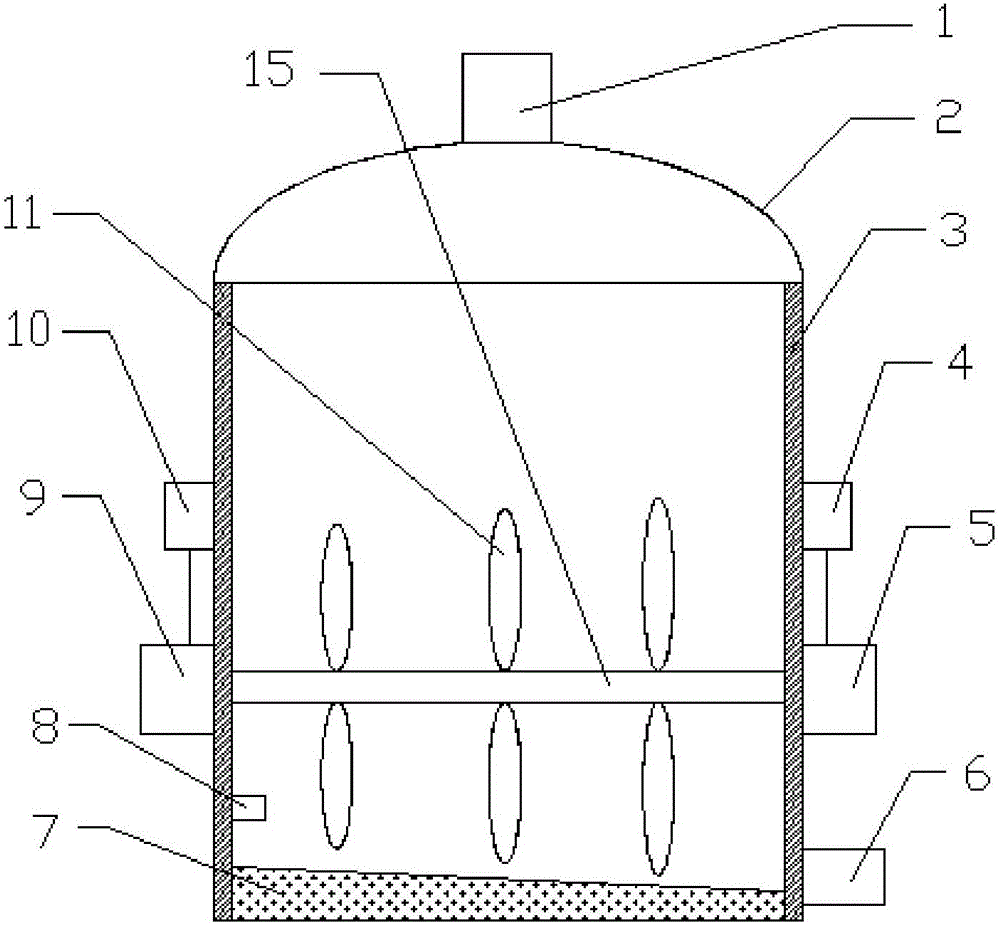

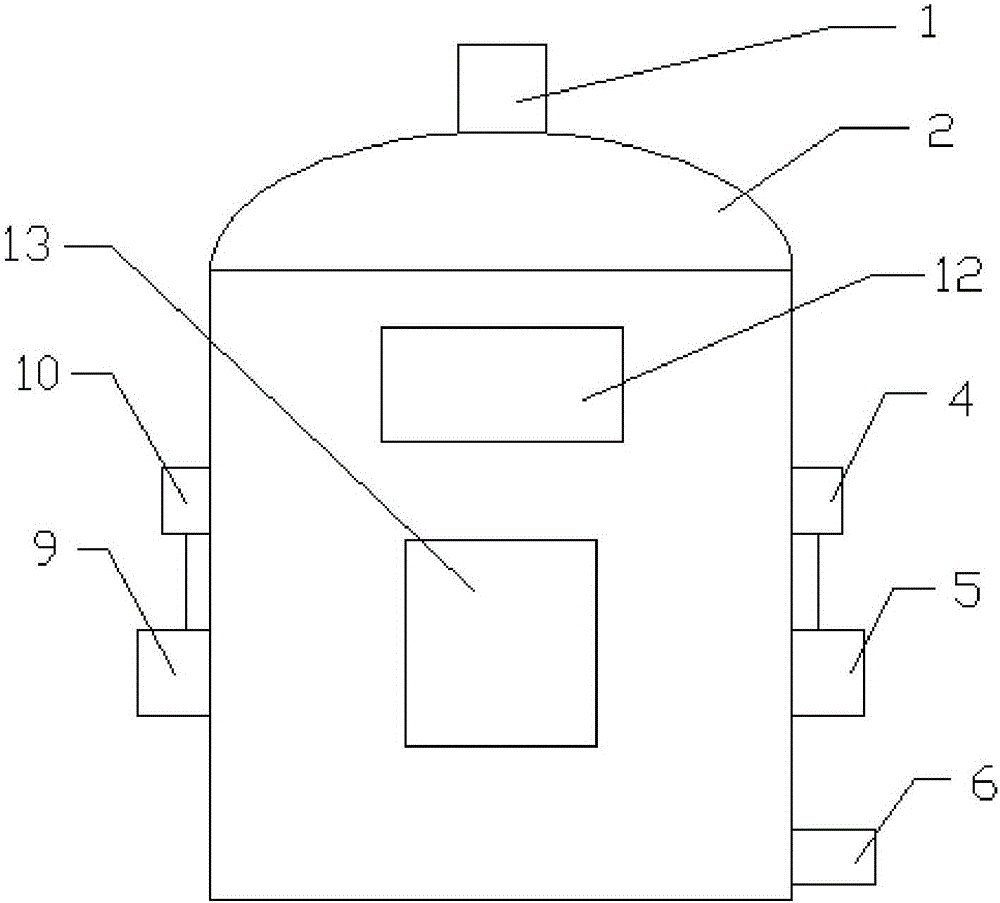

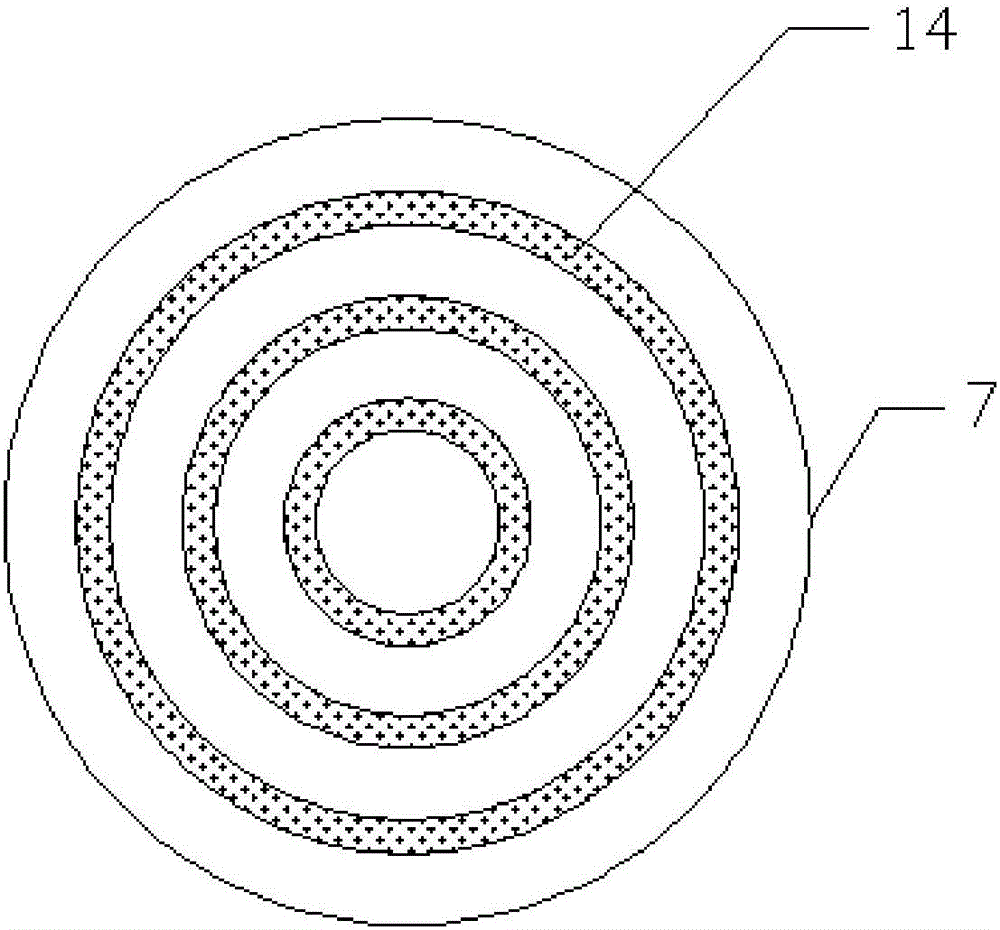

Embodiment 1

[0020] A multifunctional sol stirring device, comprising a feed inlet 1, a tank body 2, an insulation layer 3, a first motor 4, a first governor 5, a discharge outlet 6, a heating layer 7, a temperature sensor 8, a second regulator Speed 9, second motor 10, stirring paddle 11, viewing window 12, controller 13 and annular heater 14, the top center of tank body 2 is fixedly installed feed inlet 1, is also provided with viewing window 12 on tank body 2 And controller 13, two groups of motors and speed governors are respectively the first motor 4 and the first speed governor 5, the second motor 10 and the second speed governor 9, and the motors and speed governors of the two groups are respectively installed in On both sides of the tank body 2, the first speed governor 5 and the second speed governor 9 are respectively connected to the two ends of the stirring shaft 15, the first motor 4 is electrically connected to the first speed governor 5, and the second motor 10 is connected...

Embodiment 2

[0026] A multifunctional sol stirring device, comprising a feed inlet 1, a tank body 2, an insulation layer 3, a first motor 4, a first governor 5, a discharge outlet 6, a heating layer 7, a temperature sensor 8, a second regulator Speed 9, second motor 10, stirring paddle 11, viewing window 12, controller 13 and annular heater 14, the top center of tank body 2 is fixedly installed feed inlet 1, is also provided with viewing window 12 on tank body 2 And controller 13, two groups of motors and speed governors are respectively the first motor 4 and the first speed governor 5, the second motor 10 and the second speed governor 9, and the motors and speed governors of the two groups are respectively installed in On both sides of the tank body 2, the first speed governor 5 and the second speed governor 9 are respectively connected to the two ends of the stirring shaft 15, the first motor 4 is electrically connected to the first speed governor 5, and the second motor 10 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com