Planetary vacuum stirrer dynamic temperature measuring device

A technology of vacuum mixer and dynamic temperature measurement, which is applied to mixer accessories, mixers with rotating mixing devices, mixers, etc. The effect of maintaining vacuum, increasing service life and ensuring strength of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

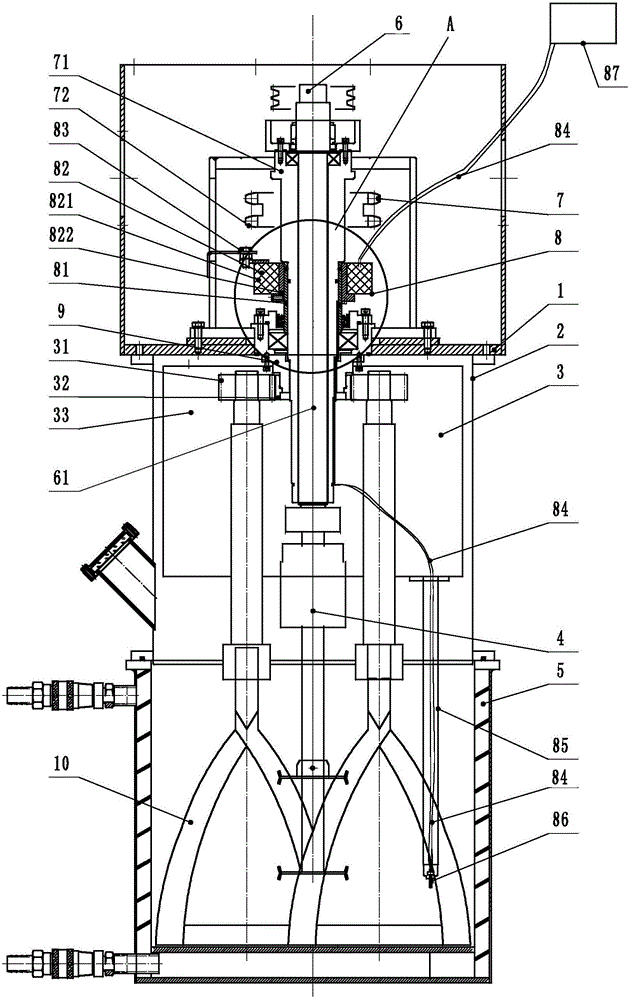

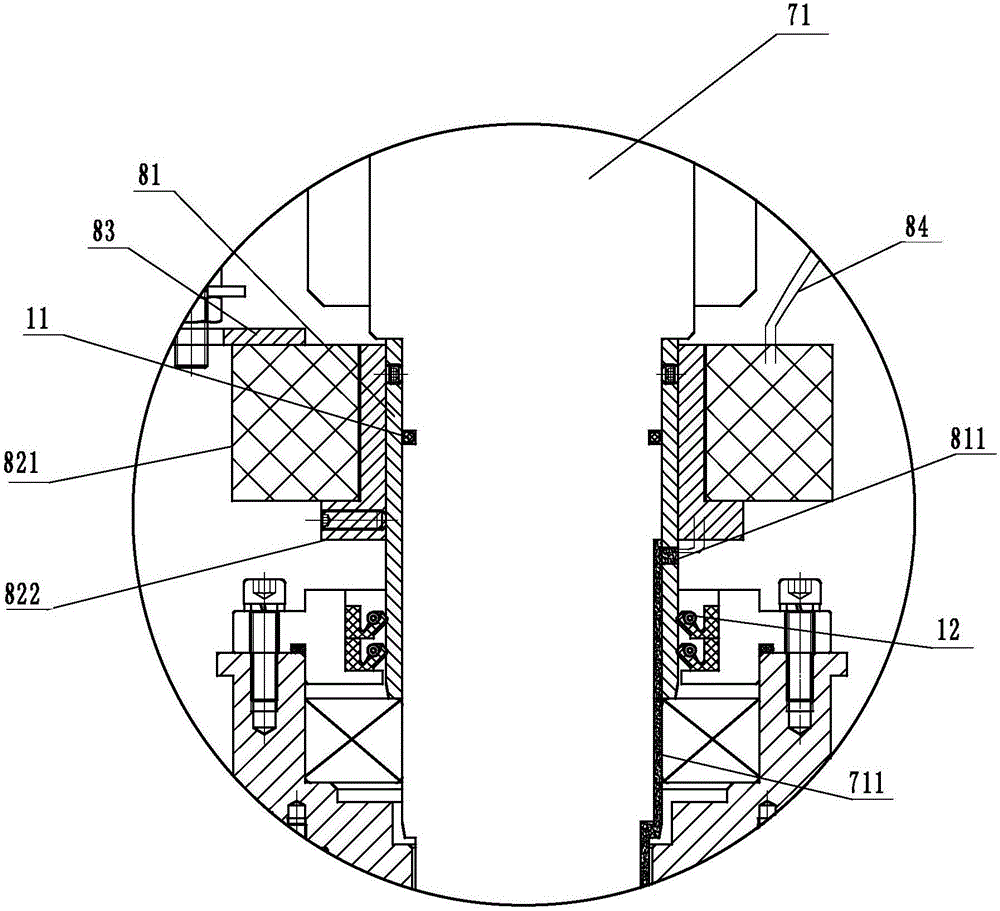

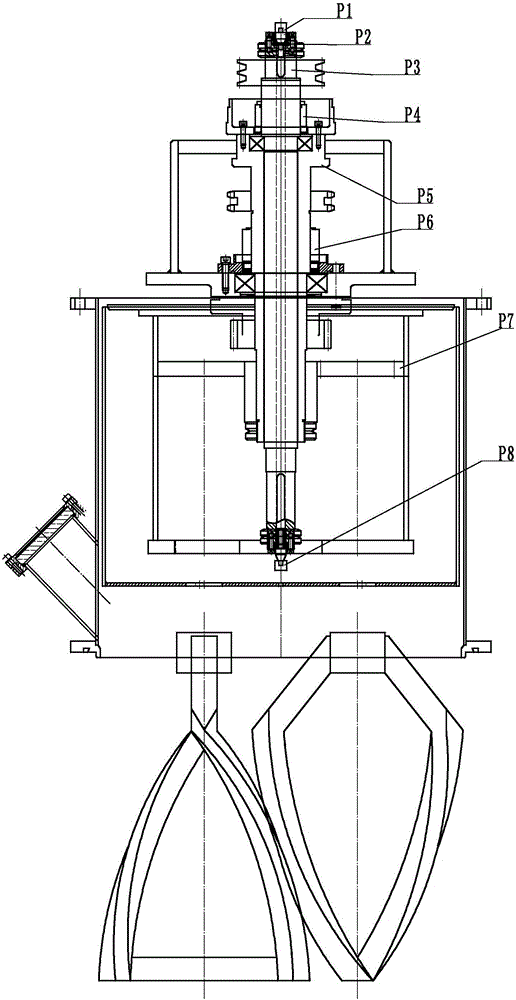

[0019] Embodiment 1: A kind of planetary vacuum mixer dynamic temperature measuring device, such as Figure 1-Figure 2 As shown, it includes beam 1, upper bucket 2, planetary component 3, mixing bucket 5, high-speed transmission component 6, low-speed transmission component 7 and dynamic temperature measurement component 8. The planetary component 3 includes planetary gear 31, sun gear 32 and The planetary box 33, the high-speed transmission part 6 includes a high-speed shaft 61, the low-speed transmission part 7 includes a hollow low-speed shaft 71, the hollow low-speed shaft is sleeved on the high-speed shaft, and the dynamic temperature measurement part 8 includes a hollow sleeve 81, a through hole type conductive slip ring 82, slip ring fixing frame 83, temperature measuring wire 84, temperature measuring rod 85, temperature measuring probe 86 and temperature information receiving / display device 87, and the through hole type conductive slip ring is composed of slip ring sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com