Pouring device for high-pressure casting mold

A high-pressure casting and casting technology, which is applied in the field of high-pressure aluminum alloy casting, can solve problems such as difficulty and reduce filling rate, and achieve the effects of stable mold filling, reduced pore defects, and avoiding erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present invention is described below in conjunction with accompanying drawing.

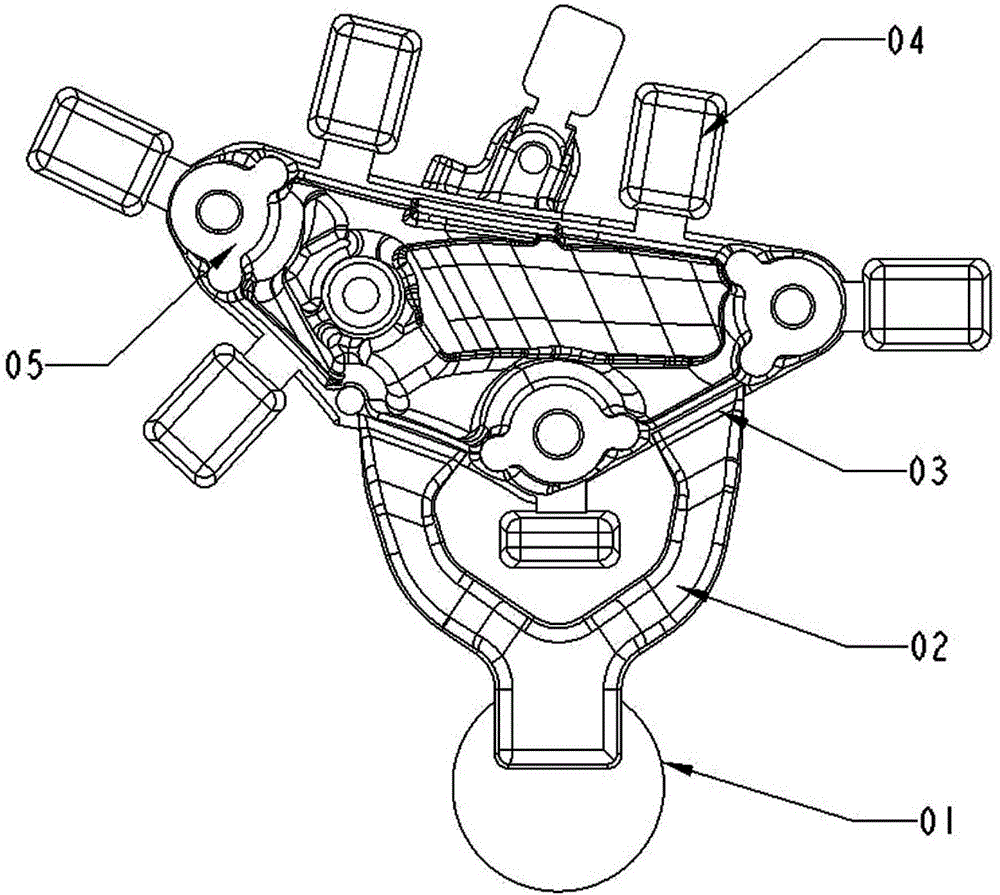

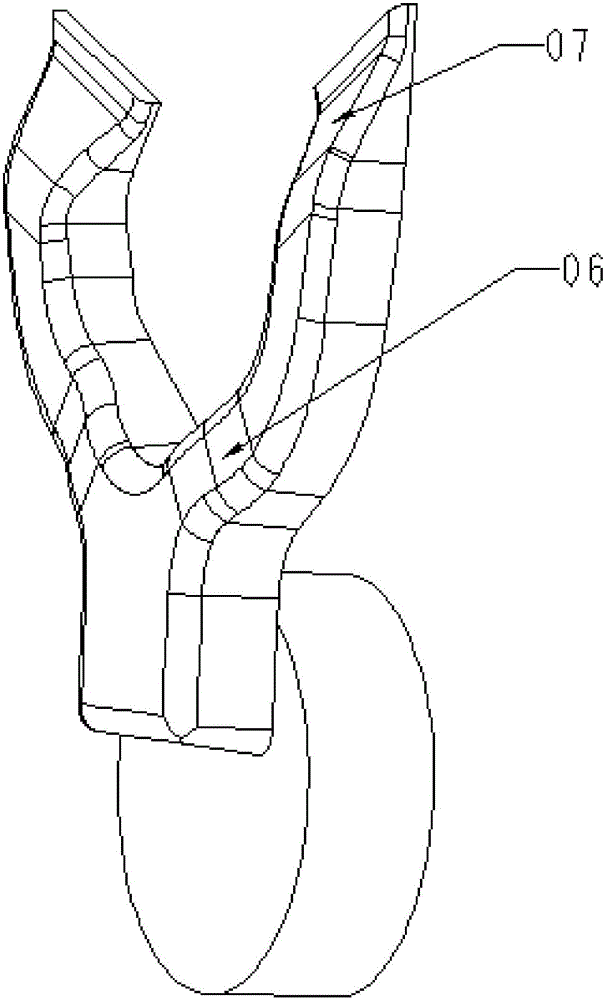

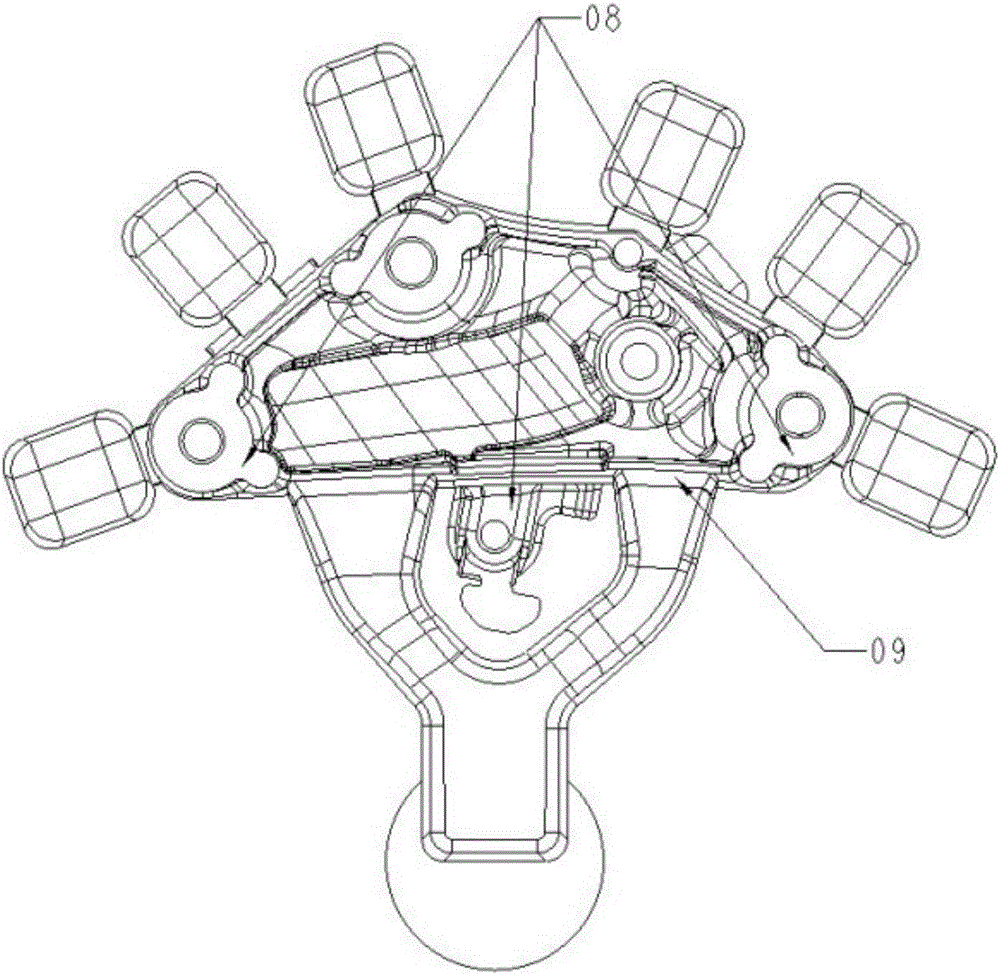

[0026] attached figure 1 It is a gating system for aluminum alloy high-pressure casting molds according to the present invention, which includes material cake (01), runner (02), ingate (03), slag accumulation bag (04), and is characterized in that : the ingate (03) is connected to the surface of the casting (05) in an overlapping form, and is arranged along the surface of the casting (05); the runner (02) is in a V-shaped structure, including being connected to The input end of the material cake (01) and the two output ends connected to the ingate (03) respectively, the bifurcation angle is in the range of 100-120°; the runner (02) faces the direction of the ingate (03) The cross-sectional area of the runner decreases step by step, and the overall thickness of the runner is reduced by 3-4mm from the bifurcation position (06) of the runner, and the rounded corners are rounded to ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com