Novel glass double-side grinding machine with functions of air washing and water washing

A technology of edge grinding machine and glass, which is applied in the direction of machine tool, grinding machine, grinding feed movement, etc., which are suitable for grinding the edge of workpieces. It can solve the problems of unfavorable cleaning of glass, waste of water resources, poor cleaning effect, etc. quality, improve cleaning effect, and reduce the frequency of cleaning water replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

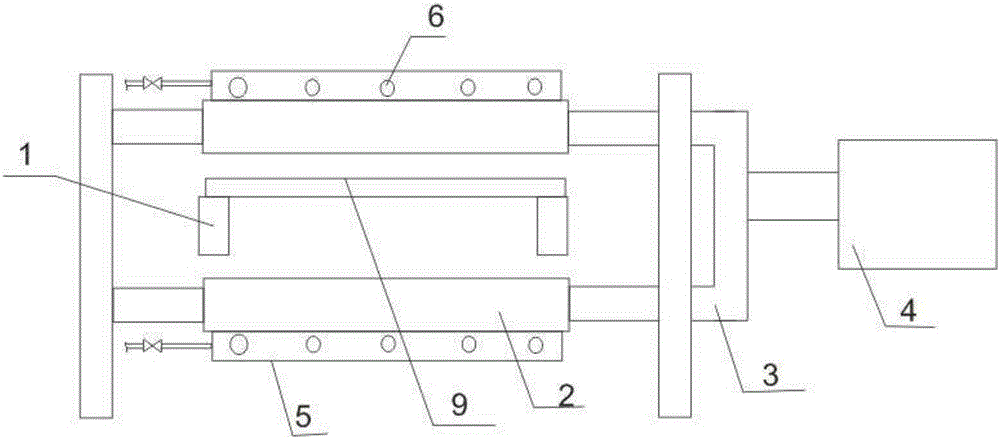

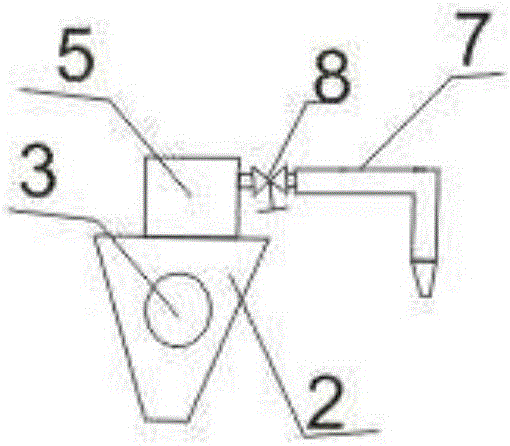

[0011] Example 1, as Figure 1-2 Shown: The novel double-sided glass edger with wind washing and water washing functions of the present invention includes a glass conveyor belt 1, an air distribution box 2, an air duct 3, a blower 4, a water distribution pipe 5, a water outlet 6, a bellows 7, and a valve 8 .

[0012] The body of the double-sided glass edging machine includes a glass conveyor belt 1, an edging system, etc. The glass conveyor belt 1 includes a conveyor chain on the left and right sides, and a rubber layer is pasted on the conveyor chain. The above structures are all in the prior art, and will not be repeated here. . Above and below the tail end of the glass conveyor belt 1 are respectively provided with air distribution boxes 2 , and the air distribution boxes 2 are mounted on the edger frames on the left and right sides of the glass conveyor belt 1 . The air distribution box 2 extends along the width direction of the glass conveyor belt 1. The air distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com