Optical fiber preform rod polishing solution circulating system

A technology of optical fiber preform and circulation system, which is applied in the direction of grinding/polishing equipment, manufacturing tools, metal processing equipment, etc. It can solve the problems of optical fiber preform mechanical properties (high brittleness, easy to scratch the surface, etc.) and achieve high integration , Easy operation and installation, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

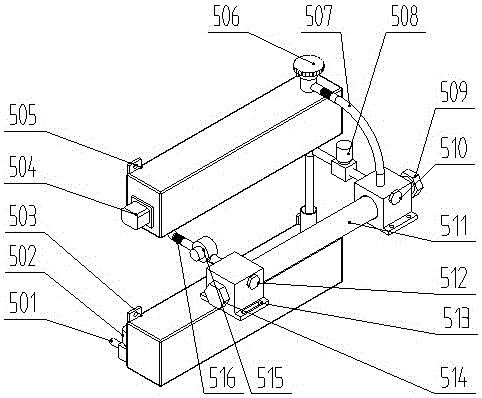

[0020] An optical fiber preform polishing liquid circulation system, the system includes an upper water tank 505, a lower water tank 503, a first conduit 501, a second conduit 516, a third conduit, an elbow 507, a first solenoid valve 502, and a second solenoid valve. Valve 508, left support seat 513, right support seat, water pump 515, agitator 504;

[0021] The upper water tank 505 is fixed on the chassis frame, and the lower water tank 503 is fixed on the chassis frame and located below the upper water tank 505;

[0022] The lower water outlet hole of the upper water tank 505 is connected to the water pump 515 through the second conduit 516, and then connected to the water inlet on the left support base 513;

[0023] The first water outlet on the right support seat is connected to the water inlet of the lower water tank 503 through the second solenoid valve 508 through the third conduit, and the second water outlet on the right support seat is connected to the water inlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com