Method and device for closed-loop regulation and control of brake pressure of train

A braking pressure and vehicle braking technology, which is applied in the direction of braking transmissions, brakes, vehicle components, etc., can solve the problems of not being able to automatically prevent the wheels from slipping, not being able to automatically detect the braking pressure, and not being able to achieve phase relief, etc., to achieve enhanced Safe and reliable performance, easy implementation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

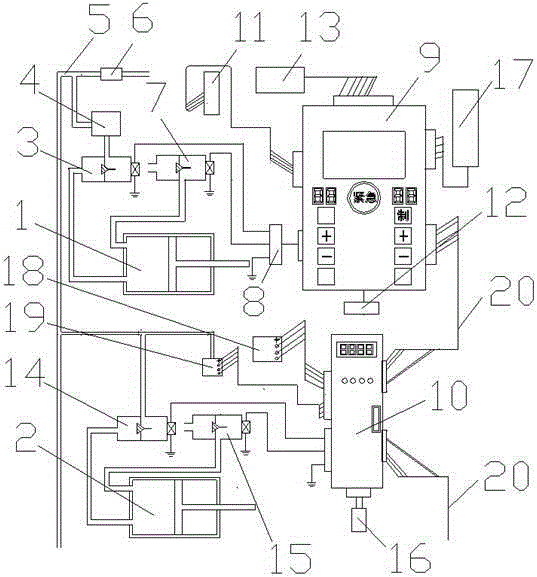

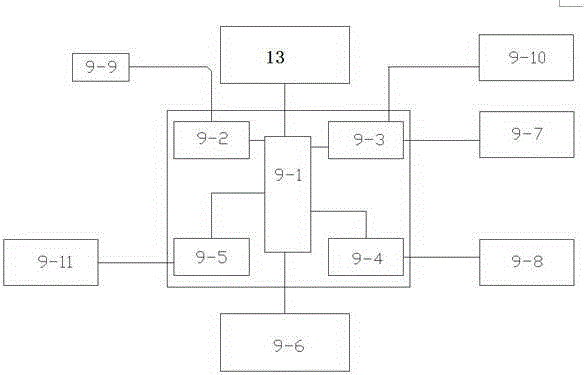

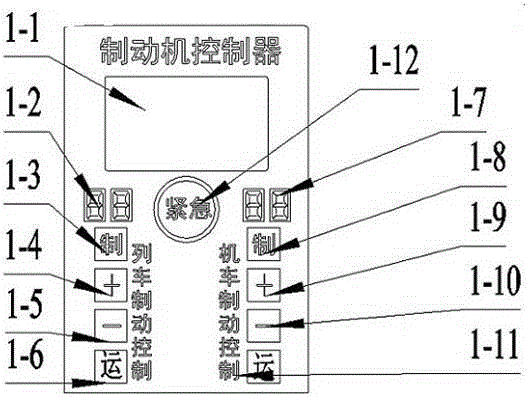

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] The embodiment of the present invention: a method for closed-loop regulation of train braking pressure, an exhaust port is added to the brake cylinder of the train, an electro-pneumatic valve is respectively set on the air inlet and exhaust port of the brake cylinder, and the controller receives To the brake pressure signal, the controller closes or opens the electro-pneumatic valve of the intake or exhaust port, thereby regulating the pressure of the working chamber of the brake cylinder to achieve braking or relief; The detected brake pressure is fed back to the controller, and the controller compares the detected brake pressure with the predetermined brake pressure. If the detected brake pressure meets the predetermined brake pressure requirements, the current working state of the brake cylinder is maintained. ; On the contrary, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com