A factory off-line calibration device for a surround view system

A calibration device and factory technology, applied in transportation, packaging, motor vehicles, etc., can solve the problems of affecting image stitching effect, high calibration environment requirements, complex calibration patterns, etc., to achieve strong scalability, strong anti-interference ability, calibration Accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

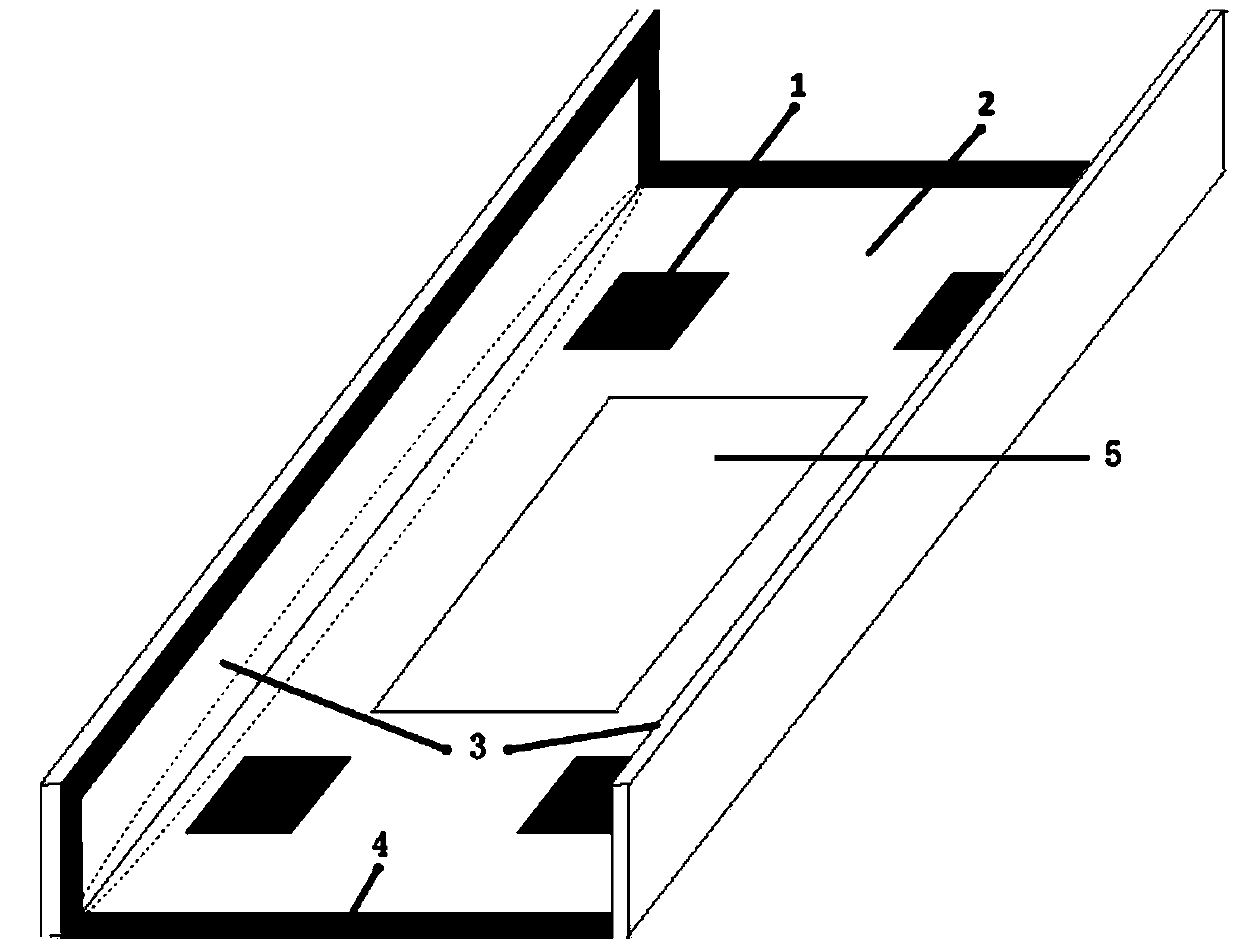

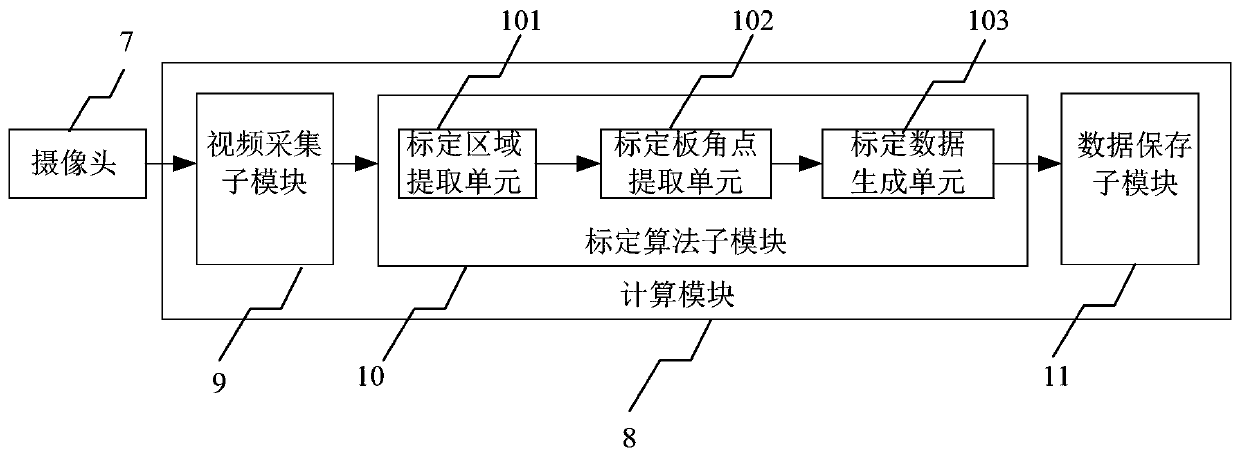

[0028] Such as figure 1 A factory offline calibration device for a surround view system is shown, the device includes a calibration platform, a camera 7 and a computing module 8, and the calibration platform includes a calibration plate 1, a white rectangular calibration area 2, a side baffle 3, and a black edge band 4 and vehicle parking location area 5.

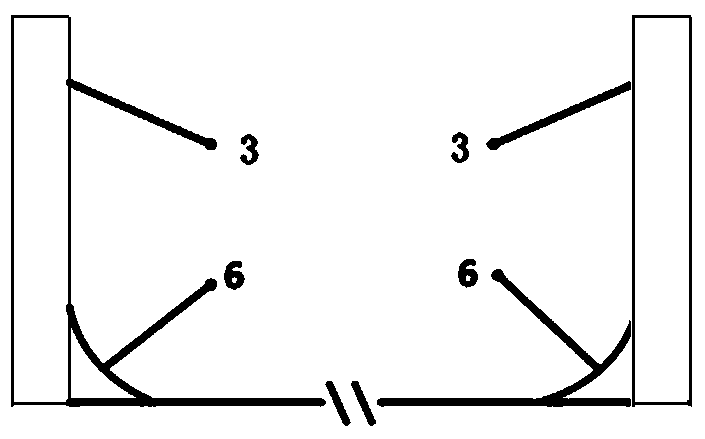

[0029] Among them, the calibration board 1 includes four black rectangular calibration boards, which are respectively tiled at the four corners of the calibration area 2; the vehicle parking position area 5 is located in the center of the calibration area 2; , used to block the surrounding environment and prevent environmental interference, thereby greatly reducing the size of the calibration site required, and ensuring that the calibration algorithm can still achieve a 100% pass rate when the calibration environment is not ideal; the black edge band is located at The overall outer edge formed by the calibration area 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com