Driving loading platform under low-temperature vacuum condition

A low-temperature vacuum and loading platform technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problem that vacuum motors cannot meet the speed, torque and working temperature, require small space, and fast loading speed and other problems, to achieve the effect of shortening the length of the transmission chain, reducing the experimental error, and facilitating real-time adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

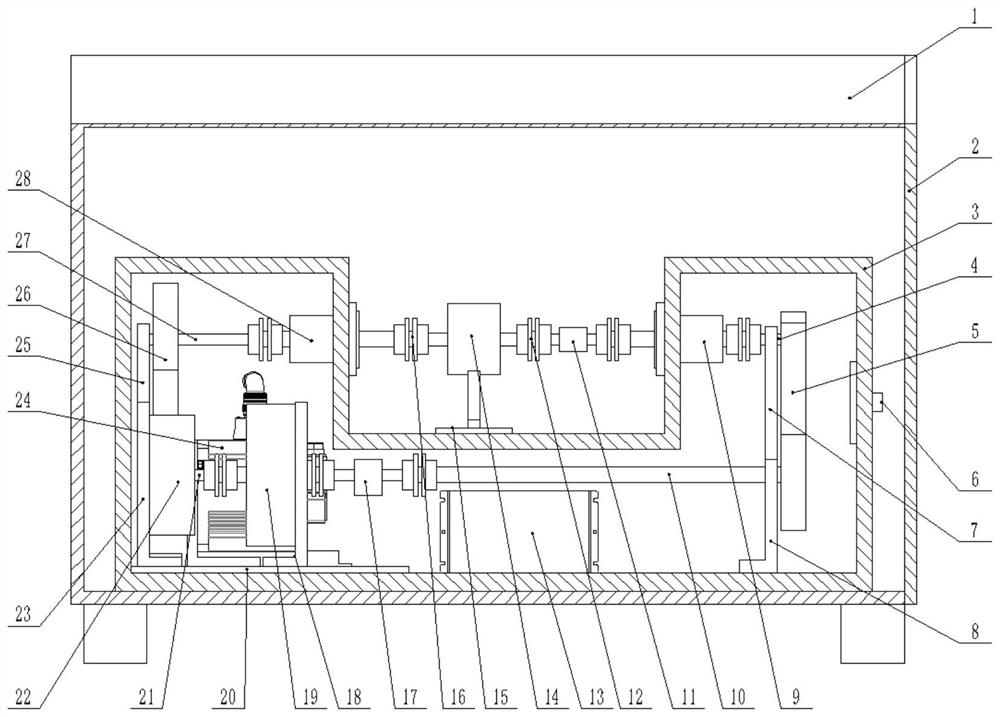

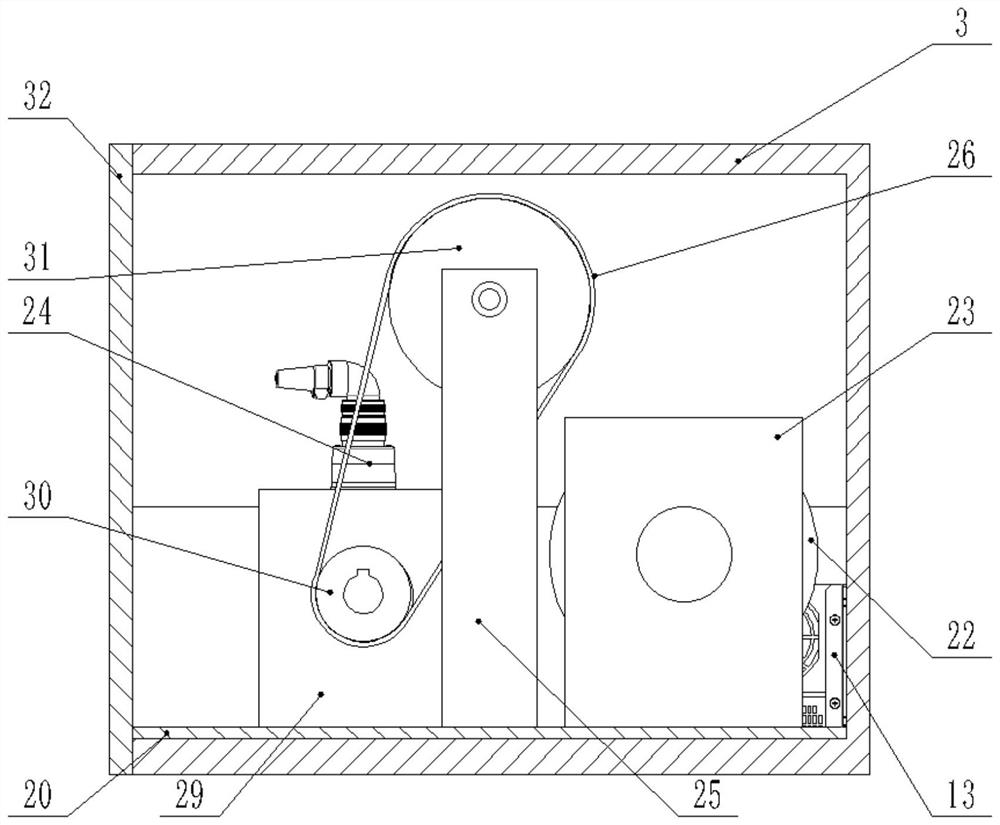

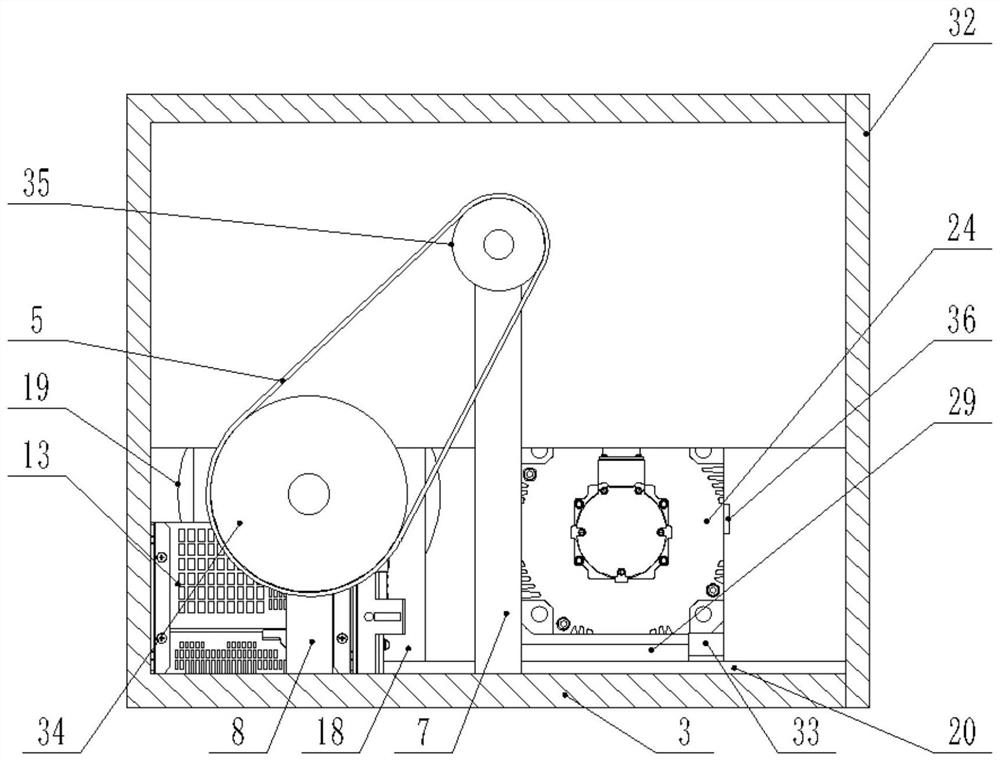

[0032] like Figure 1~3 As shown, a driving and loading platform under cryogenic vacuum conditions includes a driving device, a loading device, a first heat-insulating coupling 12, a second heat-insulating coupling 16, a third heat-insulating coupling, and a first torque Sensor 11, temperature controllable vacuum box 1, normal temperature box 3 and test piece 14, one side of temperature controllable vacuum box 1 is provided with vacuum box end cover 2, temperature controllable vacuum box 1 and vacuum box end cover 2 are composed The vacuum box has its own temperature regulation and the function of realizing vacuum environment, which can realize low temperature vacuum environment.

[0033] The normal temperature box 3 is designed as a hollowed-out concave line, and the side wall is processed with a circular through hole for installing the connector flange 6. The normal temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com