Friction experiment device suitable for low-temperature vacuum condition

An experimental device, low temperature vacuum technology, applied in the direction of using mechanical devices, measuring devices, instruments, etc., can solve the problems of inability to meet the rotation speed, torque and working temperature, fast loading speed, small required space, etc., and shorten the length of the transmission chain. , reduce the experimental error, inhibit the effect of heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

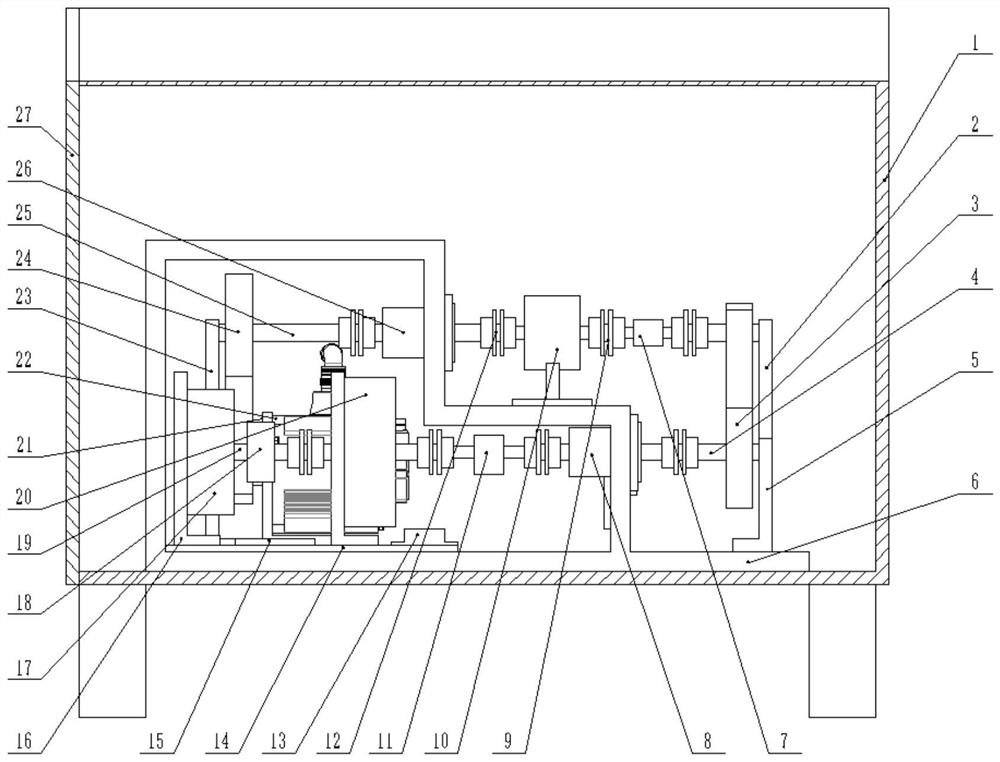

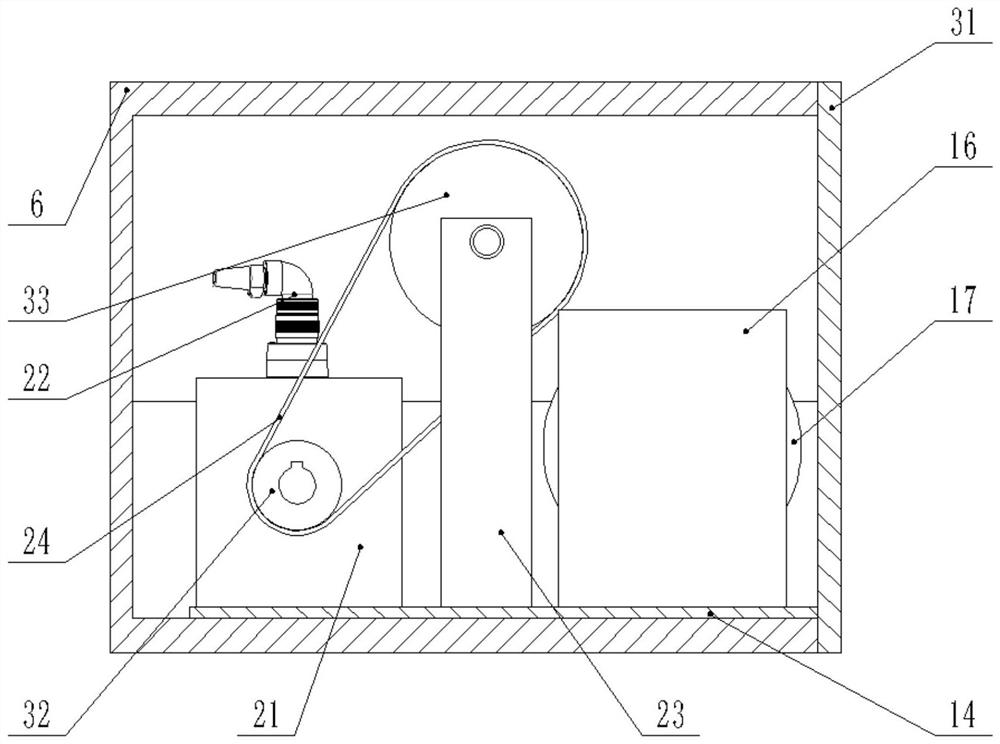

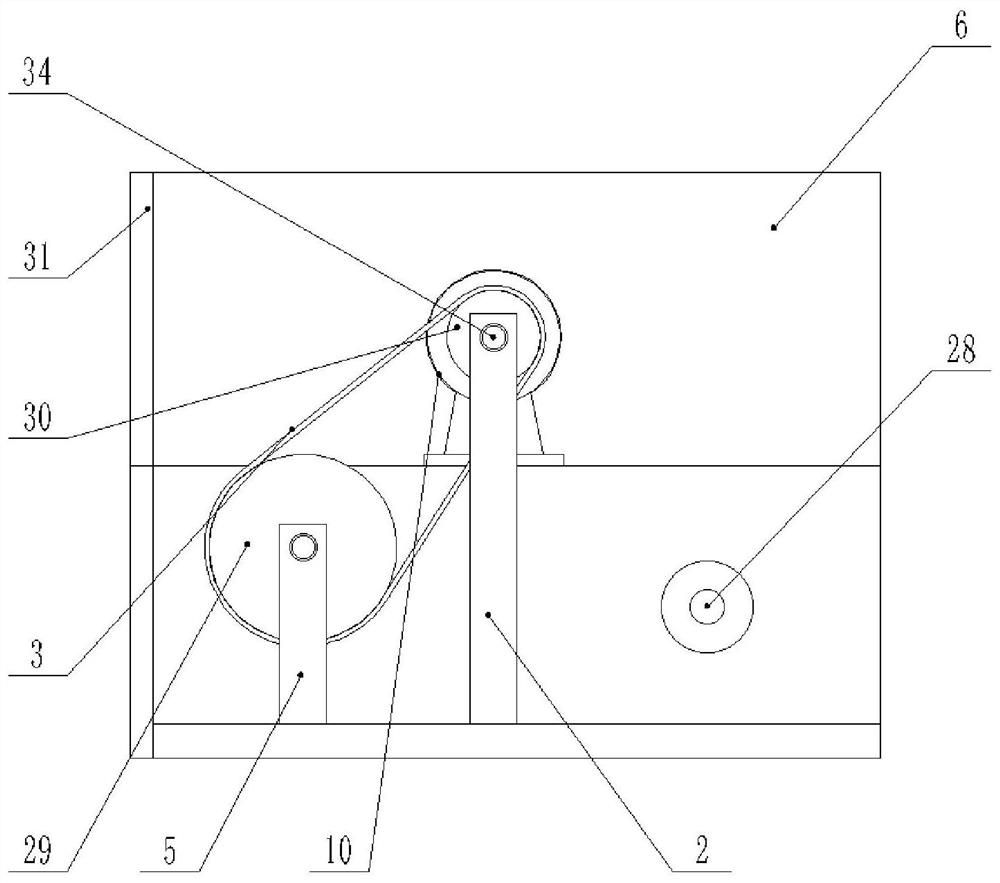

[0031] The present invention will be further described below in conjunction with accompanying drawing:

[0032] Such as Figure 1~4 As shown, a friction experiment device suitable for low-temperature vacuum conditions includes a driving device, a loading device, a transmission device, a second heat-insulating coupling 12, a temperature-controllable vacuum box 1, a room temperature box 6 and a test piece 10, One side of the temperature-controllable vacuum box 1 is provided with a vacuum box end cover 27 . The test piece 10 is provided with a loading input end and a driving end, and the loading input end and the driving end are two ends of the same shaft on the test piece 10; the normal temperature box 6 is arranged in the temperature-controllable vacuum box 1, and the normal temperature box 6 A heat-insulating mounting plate 14 installed horizontally is arranged on the inner bottom surface, and the driving device and the loading device are installed in the room temperature box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com