Adhesive-film-winding automatic packaging machine for floor group

A technology of automatic packaging machine and floor group, applied in the direction of packaging, rotating wrapping of articles, etc., can solve the problems of poor moisture resistance and high packaging cost, and achieve the effect of strong moisture resistance, low packaging cost, and not easy to be wet and loose.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

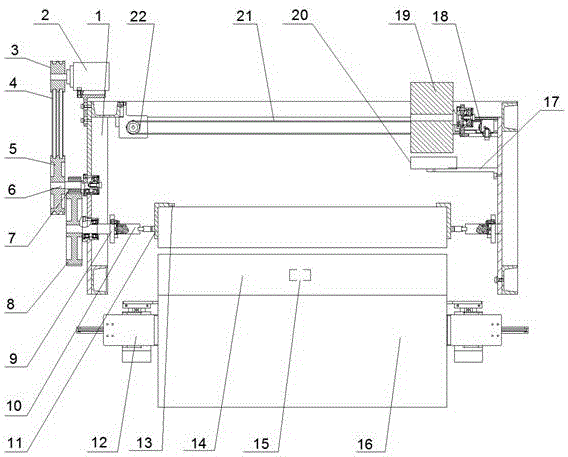

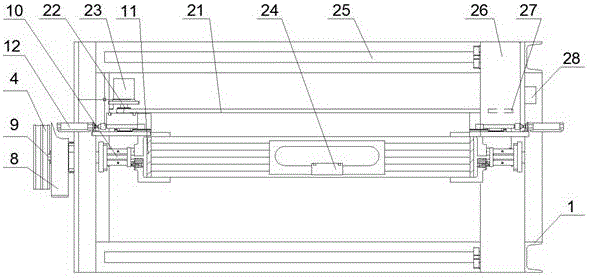

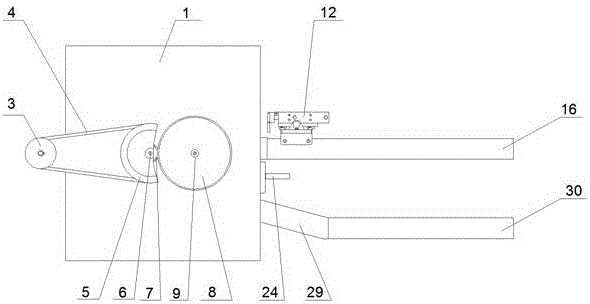

[0011] specific implementation plan

[0012] The present invention will be described in detail below in combination with embodiments and with reference to the accompanying drawings.

[0013] see Figure 1-3 , this film winding floor group automatic packaging machine includes stand 1, floor group rotation assembly, floor group clamping and positioning assembly, film cutting assembly, film cylinder reciprocating movement assembly, floor transmission system and control system PLC seven Part; the upper left part of the floor group rotation assembly is the motor 2, connected with the coaxial pulley 3, connected with the drive pulley 5 through the drive belt 4, and connected with the drive pinion 7 through the rotating shaft A6 to the right, and the latter is connected with the drive gear 8 Engaged, connected with the floor group clamping and positioning components through the rotating shaft B9; the floor group clamping and positioning components include the clamping and positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com