Directional rotary plate feeding device

A technology of directional rotation and rotation of the main shaft, applied in packaging and other directions, can solve the problems of wasting time, lengthening the assembly line, and occupying a large area of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

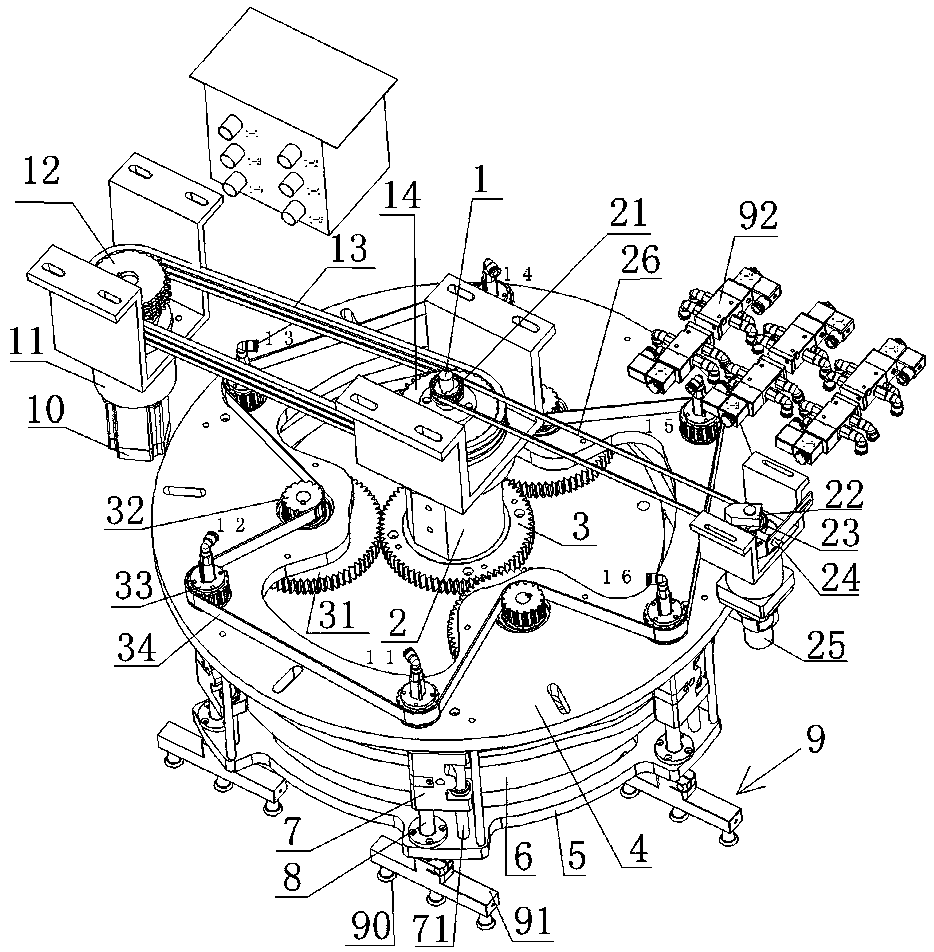

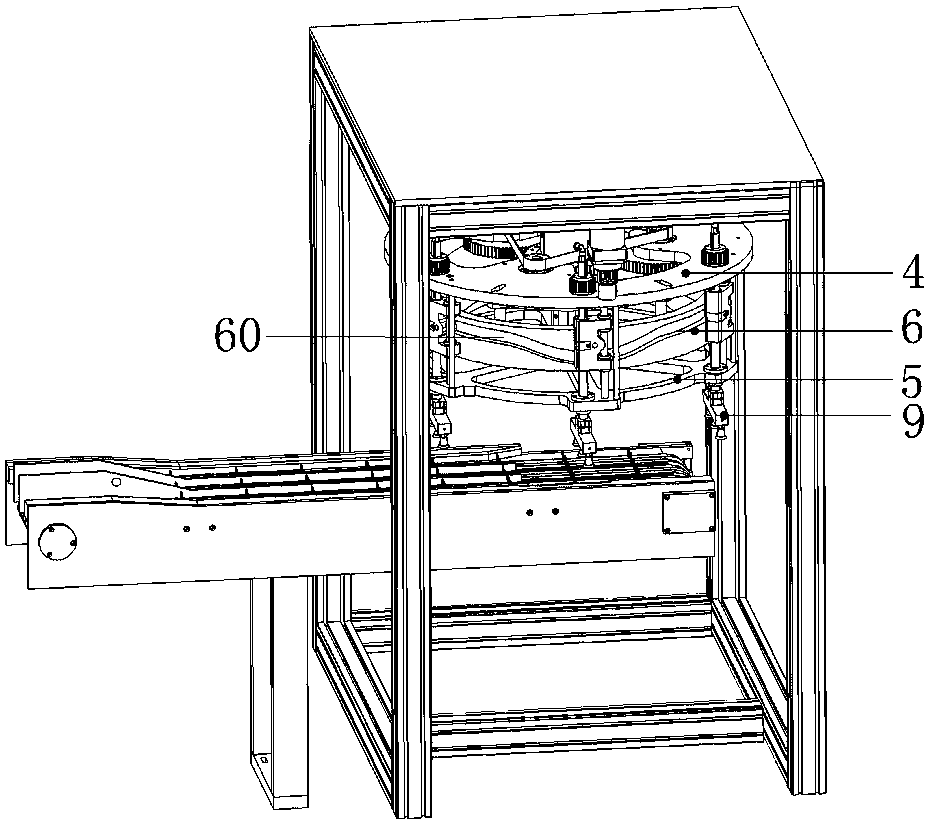

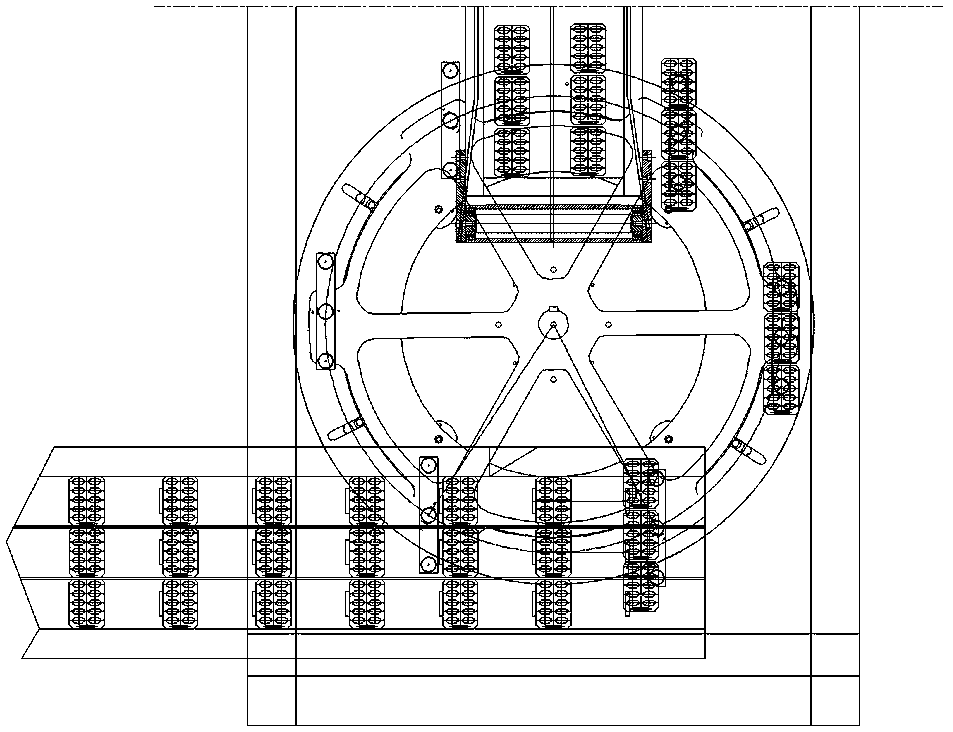

[0013] Such as image 3 As shown, the directional rotary plate feeding device acts as a mechanism between the conveyor belt of the blister machine and the conveyor belt of the cartoning machine, and plays the role of a manipulator, that is, the blister plate (also called a plate) on the conveyor belt of the blister machine The blister plates are transported to the conveyor belt of the cartoning machine, and the blister plates are packed by the cartoning machine.

[0014] From image 3 It can be seen that a conveyor belt of the blister machine has three assembly lines, indicating that the blister machine is 3 versions / cutting, and a conveyor belt of the cartoning machine has two assembly lines, and the two conveyor belts are perpendicular to each other. The conveying method of the directional rotary plate feeding device can send the three plates side by side on the three lines of the conveyor belt of the blister machine to one or more lines of the conveyor belt of the cartonin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com