Sealing machine

A sealing machine and rack technology, applied in the field of sealing machines for ice packs, can solve the problems of inconvenient repair, large floor space, complicated installation, etc., and achieve the effects of easy-to-understand structure, easy procurement, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

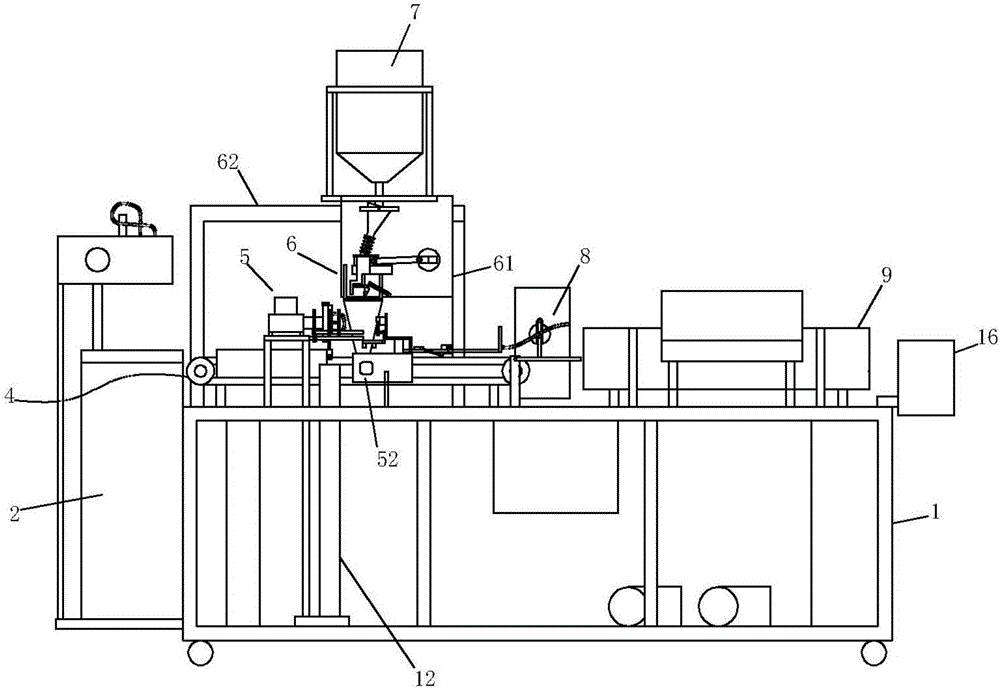

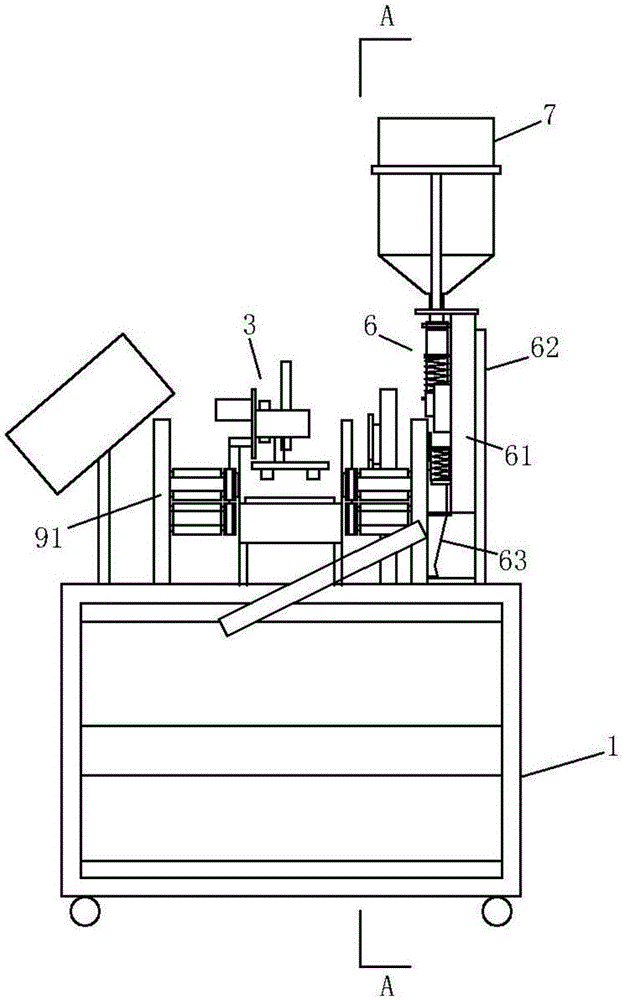

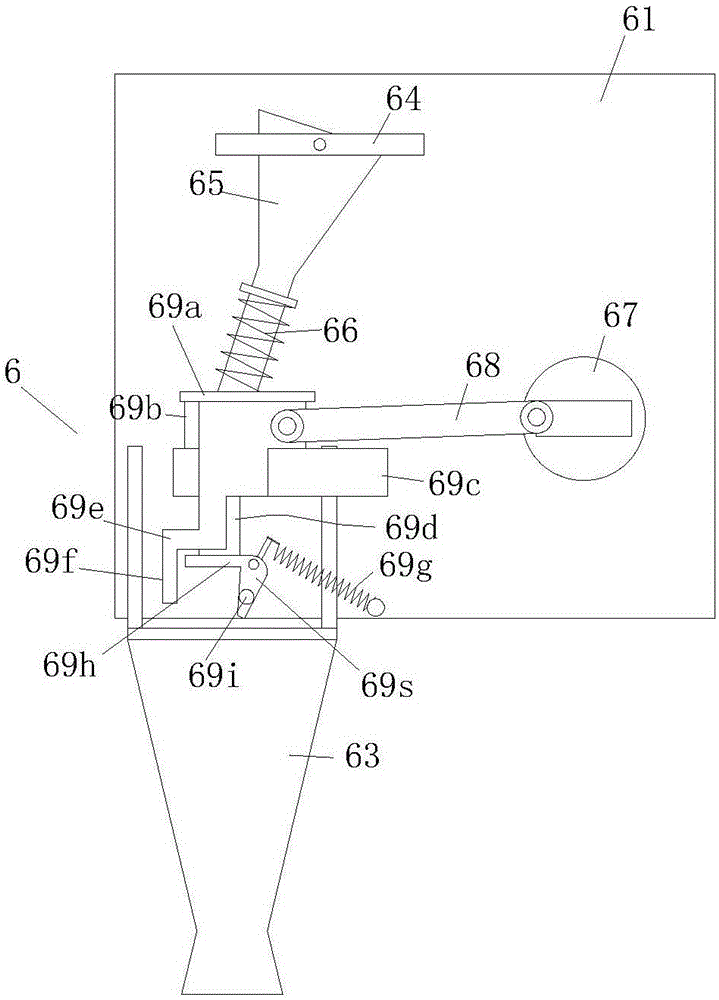

[0030] The sealing machine as shown in the accompanying drawings includes a frame 1 and a working device arranged on the frame 1 and composed of control, power supply, injection, conveying, hot pressing modules 9 and related auxiliary modules, containing packaging bags 100 The first material box 2 is set on one side of the frame 1, the packaging bag 100 in the first material box 2 is transported to the delivery module 4 by the delivery device, and the resin delivery module 6 and the water injection bag delivery module 5 take the delivery module 4 as the axis Symmetrically arranged on the frame 1, the hot pressing module 9 is arranged at the end of the delivery module 4, the resin delivery module 6 includes a support frame 62 arranged on the frame 1, and a first mounting plate fixed on the support frame 62 61. The control and valve assembly arranged on the first installation plate 61, the resin storage tank 7 arranged above the first installation plate 61 and the discharge nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com