Automatic container overturning machine

A technology of automatic turning and turning of boxes, applied in the parts, packaging, loading/unloading of tableware washing machine/rinsing machine, etc., can solve the problems of affecting the cleaning of tableware, unstable turning of boxes, and heavy bottom of turners, etc. Manpower saving, simple structure, reliable effect of turning over boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

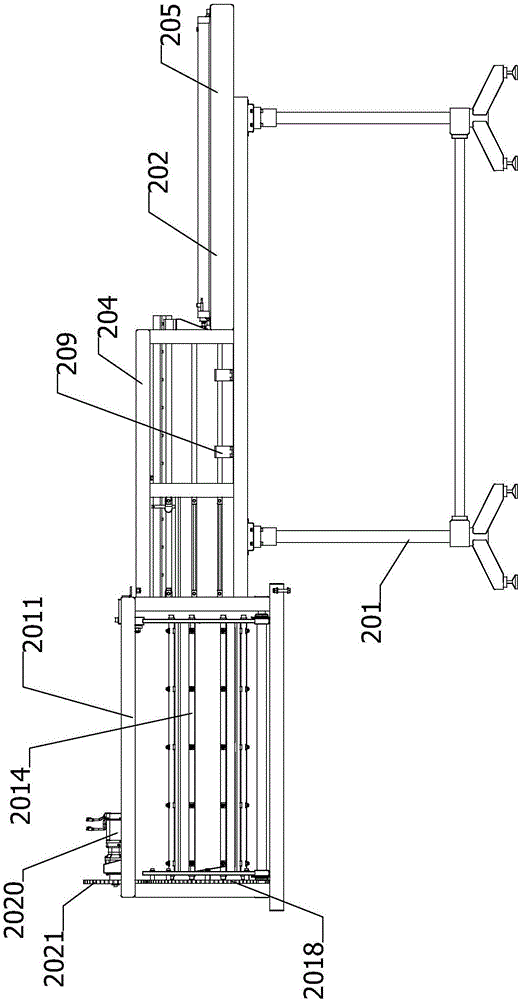

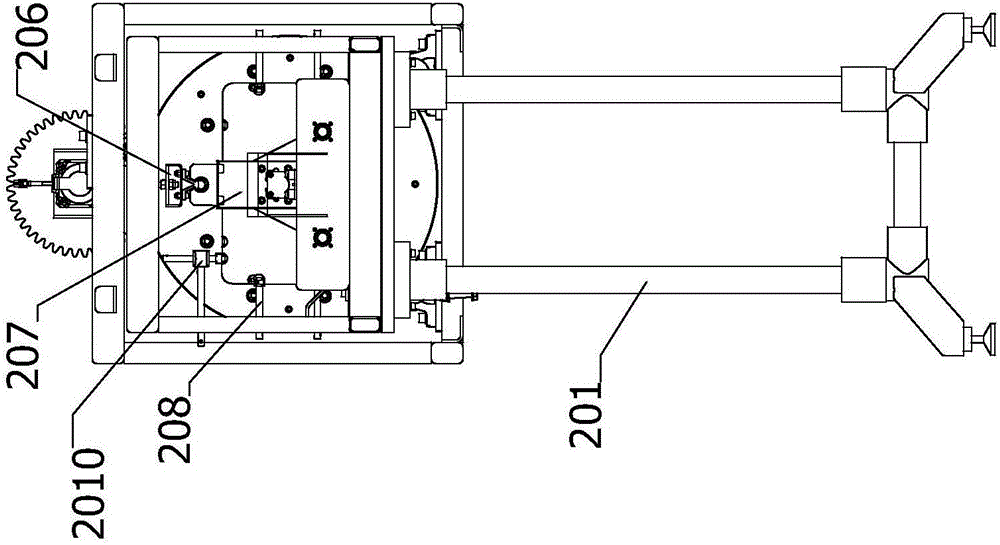

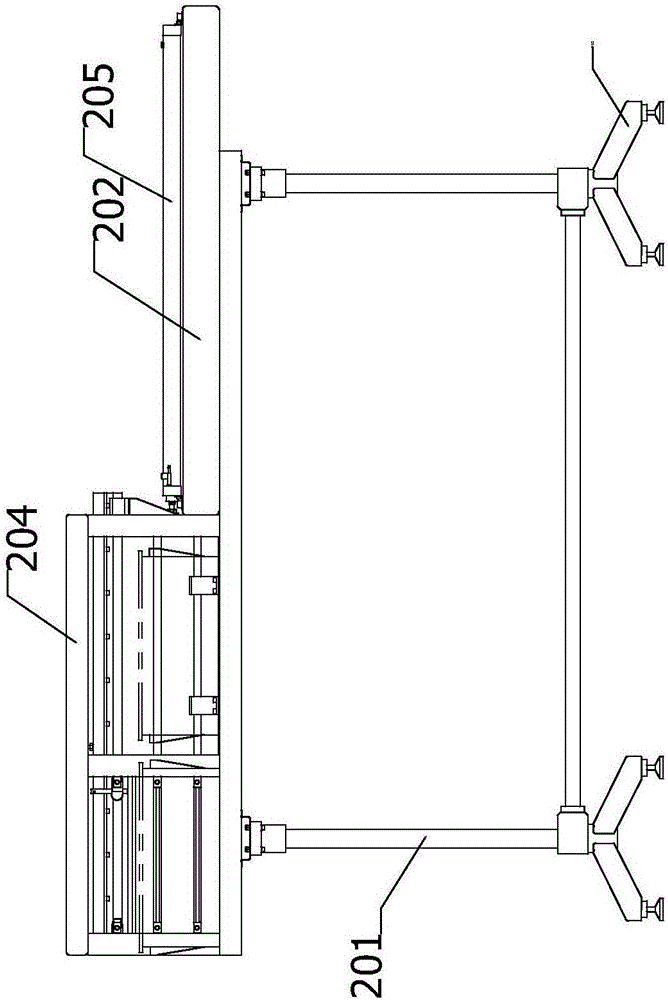

[0022] Such as Figure 1-7 As shown, the automatic box-turning machine is made up of a box-pushing device and a box-turning device. The box-pushing device includes a bracket 201 and a cylinder bracket 202. The cylinder bracket 202 is supported on the bipod bracket 203 by the bracket 201. The cylinder of the cylinder bracket 202 One side of the push rod is the case-in support 204, the cylinder support 202 is provided with a cylinder 205, the top of the case-in support 204 is provided with a linear guide rail 206, and the push box plate 207 pushed by the cylinder push rod is slidably arranged on the linear guide rail 206, One side inside the support 204 is provided with an aluminum rail guardrail 208, and the other side bottom inside the box support 204 is provided with a box positioning plate 209 inclined towards the inside of the box support 204, so that the box positioning plate 209 is placed on the box support 204. The height of the inner end is lower than the height of its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com