Solid-liquid separating system in sewage treatment

A technology for solid-liquid separation and sewage treatment, which is applied in the fields of water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc. It is easy to maintain and repair, improve the efficiency of sewage treatment, and achieve the effect of complete solid-liquid separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

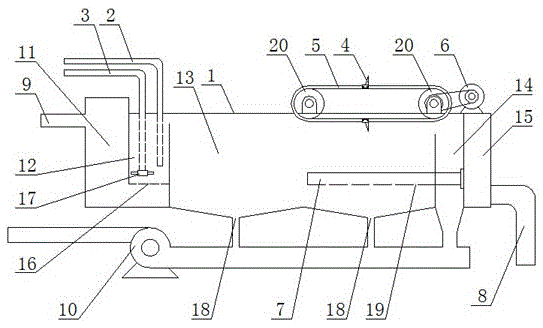

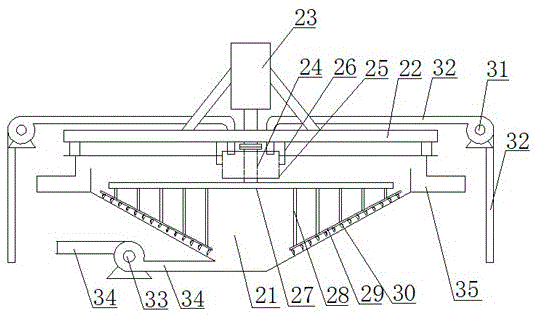

[0013] Depend on figure 1 and figure 2 As shown, the solid-liquid separation system in sewage treatment is composed of a solid-liquid separation floating device and a solid-liquid separation sinking device. Mud scraper 4, mud scraper conveyor chain 5, mud scraper drive motor 6, water delivery pipe 7, drain pipe 8, water inlet pipe 9 and sewage pump 10, the tank body 1 is separated from left to right by partitions There is a water inlet chamber 11, a mixing chamber 12, an air flotation chamber 13, a sewage discharge chamber 14 and a drainage chamber 15. The water inlet pipe 9 communicates with the water inlet chamber 11 of the pool body 1, and the water inlet chamber 11 and the mixing chamber 12 pass through The water hole 16 opened at the bottom of the partition is connected, and one end of the gas feeding pipe 2 and the drug feeding pipe 3 are respectively located at the bottom of the mixing chamber 12, so that the sewage gushing out from the bottom of the mixing chamber 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com