Building self-repair system and constructing method and application thereof

A self-repairing and building structure technology, applied in building maintenance, building construction, construction, etc., can solve problems such as time-consuming and material-consuming, impact on the safety and firmness of building structures, and easy cracking, so as to achieve better healing effect, Quickly heals cracks in the wall and saves raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

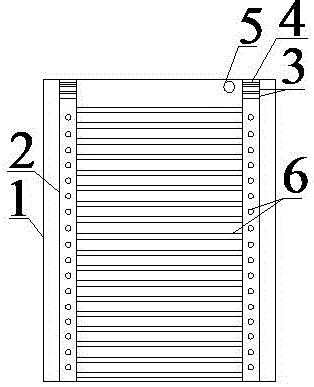

[0034] A building self-repair system includes repair pipes 6 filled with adhesive distributed inside the building structure, and the repair pipes 6 are brittle pipes.

[0035] Preferably, the repair pipe 6 is a pipe structure with two parallel pipes, the repair pipe 6 is a double-hole pipe, and two-component chemical adhesives are respectively poured into the repair pipes. The two-component chemical adhesive is a flame-retardant polyurethane grouting material and its catalyst. The material of the repairing pipe 6 is glass or ceramics, and the wall thickness is 1mm; preferably, the repairing pipe 6 can be arranged in a straight line or in a continuous U-shape.

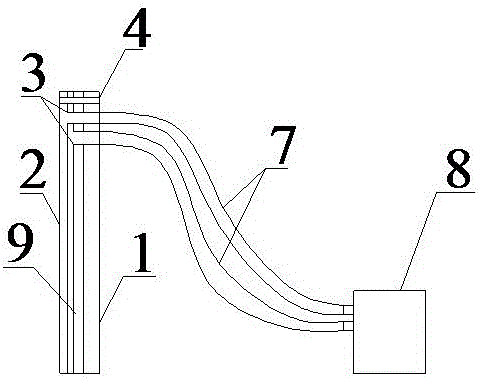

[0036] Preferably, a main slurry delivery pipe 2 communicating with the repair pipe is distributed inside the building structure. The main slurry delivery pipe 2 is a double-pipe parallel pipeline structure, and catalysts and grouting materials are respectively injected in the two pipelines; preferably, the main slurry...

Embodiment 2

[0039] A construction method of a building self-repair system, comprising the following steps:

[0040] (1) Two main slurry pipes 2 are installed on the left and right sides of the building wall structure, and the distance from the walls on both sides is 200mm-600mm;

[0041] (2) Open an air hole 4 on the upper part of each pipe of the main grouting pipe 2 to discharge the air in the pipe, and open a grout inlet 3 at the lower part of the air hole. After the grouting is completed, the grout inlet 3 and the air hole 4 must be closed;

[0042] (3) Set a group of continuous U-shaped or several straight double-hole repair pipes 6 between the two main slurry delivery pipes 2, connect the double-hole repair pipes 6 with the main slurry delivery pipes 2 on the left and right sides, and repair the pipes 6 The distance between each other is 100mm-400mm;

[0043] (4) Build a building wall, the distance between the building wall and the main slurry pipe 2 is 200mm-600mm;

[0044] (5) ...

Embodiment 3

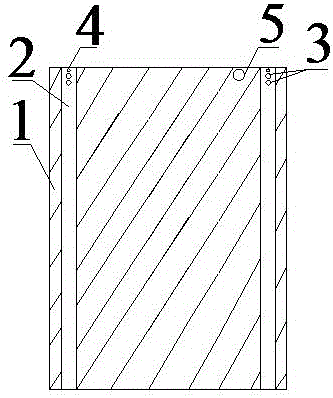

[0045] Embodiment 3 Application of the self-repairing system of the present invention on the structure of the closed wall of the mine

[0046] The repair pipes used in this embodiment are several linear glass pipes, the closed filling material used is foamed concrete, and the two-component adhesive used is flame-retardant polyurethane grouting material and its catalyst.

[0047] Two main slurry delivery pipes 2 are respectively installed on the left and right sides of the position where the airtight wall needs to be set, and the distance from the roadway walls on both sides is 200mm-600mm, and an air hole 4 is opened on each pipeline upper part of the main slurry delivery pipeline 2. In order to discharge the air in the pipeline, a slurry inlet 3 is opened at the lower part of the air hole, and a number of linear double-hole quartz glass repair pipes 6 are arranged between the front and rear main slurry pipes 2, and the repair pipes 6 are connected to the main delivery pipes on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com