Assembled type crown beam, surrounding purlin and waist beam structure

A prefabricated and enveloped structure technology, applied in infrastructure engineering, construction, excavation, etc., can solve the problems of high cost, difficult construction, long construction period, etc., achieve low project cost, high degree of component assembly, and save engineering material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

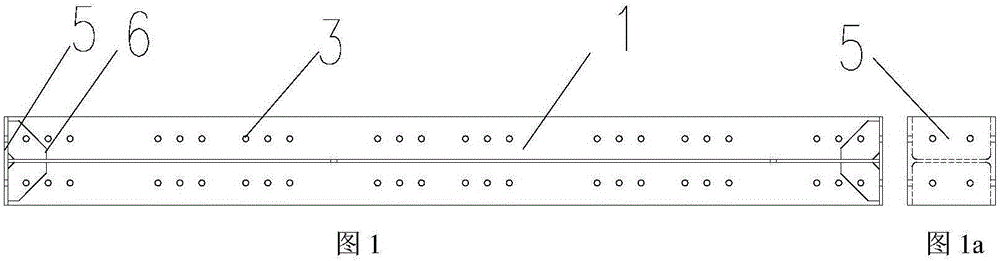

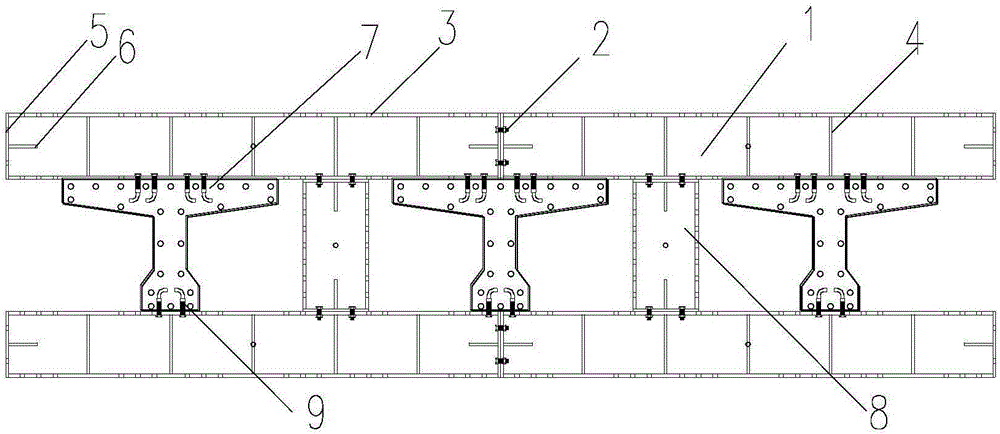

[0038] Examples are as follows: the prefabricated crown beam, purlin and waist beam are assembled by multi-ribbed H-shaped steel standard beam 1 through connecting bolts 2; multi-ribbed H-shaped steel standard beam 1 is made of H-shaped steel material and steel plate in the factory It is processed in the workshop, and its length is designed according to the modulus. On the flange plates on both sides of the H-shaped steel, that is, the connecting surface is processed with connecting bolt holes 3 according to the standard modulus. Along the axis of the H-shaped steel, at a certain distance, the stiffeners 4 are welded on both sides of the web, and multi-ribbed The two ends of the plate-type H-shaped steel standard beam 1 are welded with end connecting plates 5 and stiffeners 6, and connecting bolt holes 3 are processed on the end connecting plates 5, see Fig. 1 and Fig. 1a.

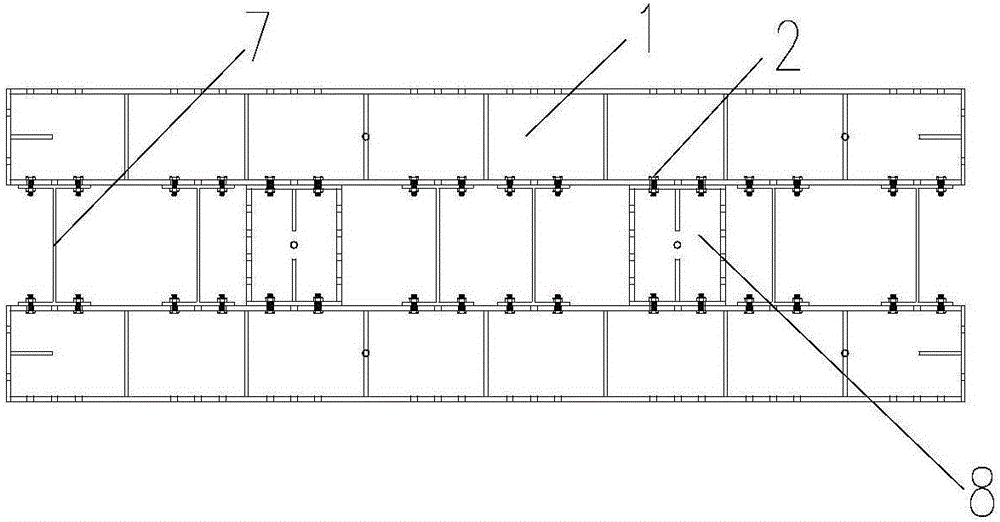

[0039] On both sides of the top of the steel sheet pile 7 of the vertical enclosure structure, the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com