Interlayer fire blocking structure of curtain wall based on raised floor design and its construction method

A raised floor, fire blocking technology, applied in fire prevention, walls, building components and other directions, can solve the problems of low sealing between layers, complicated construction procedures, difficult to operate, etc., to achieve good fire sealing effect and construction safety. Civilized, easy to install effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

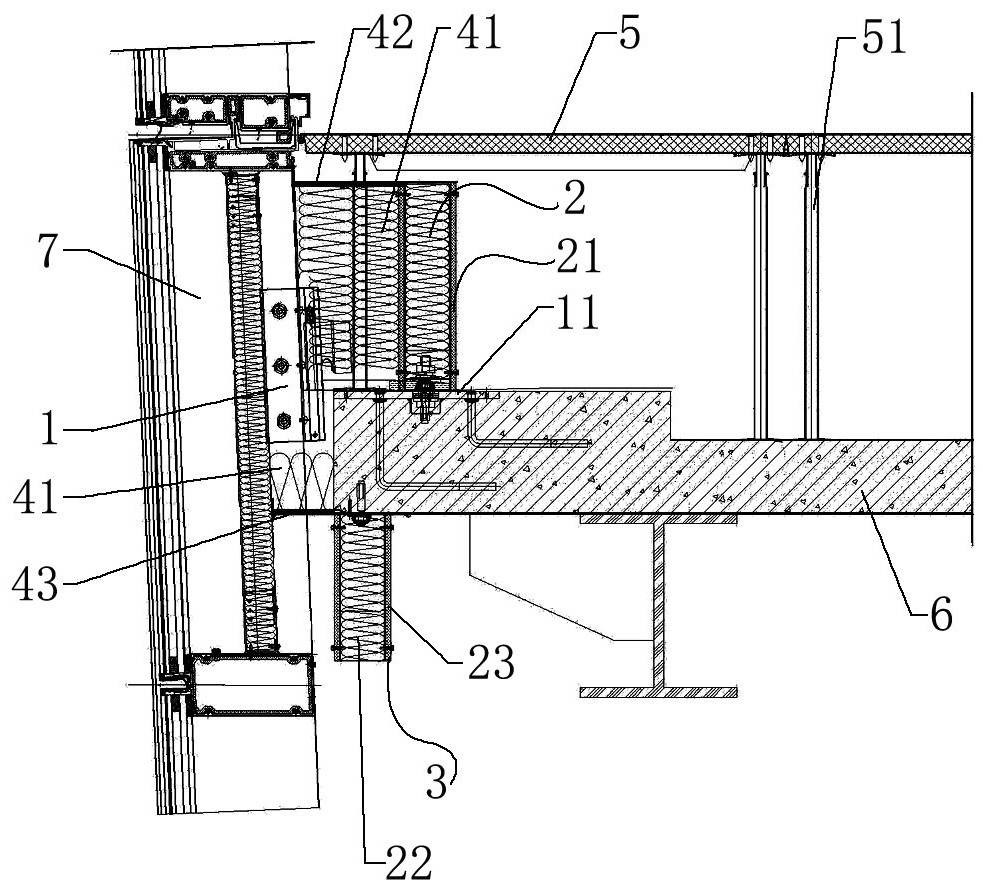

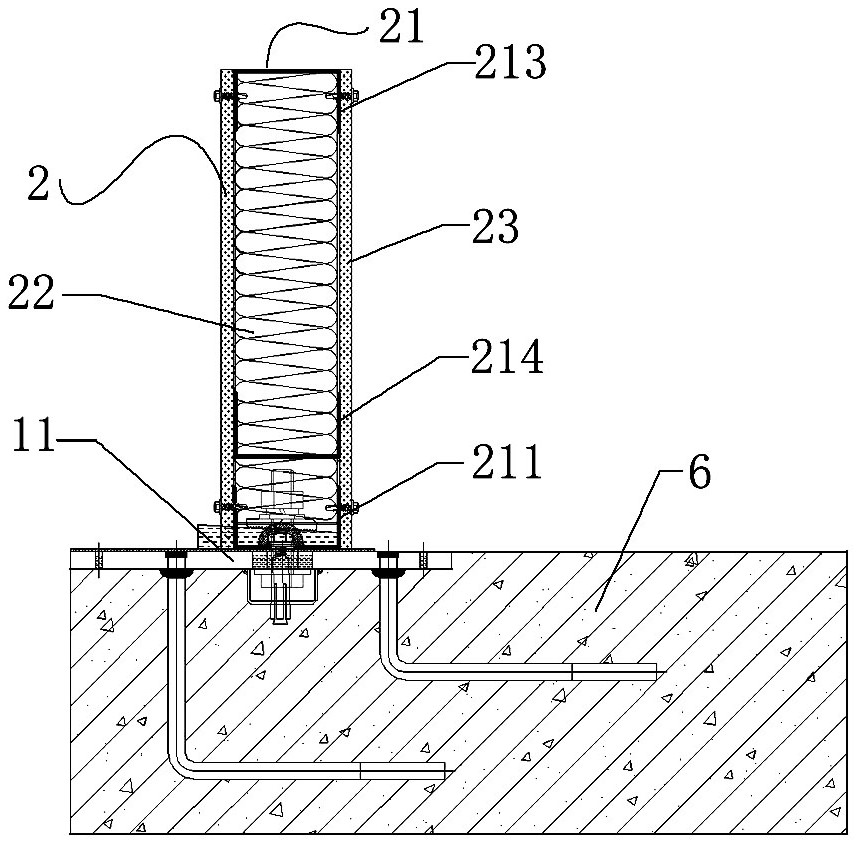

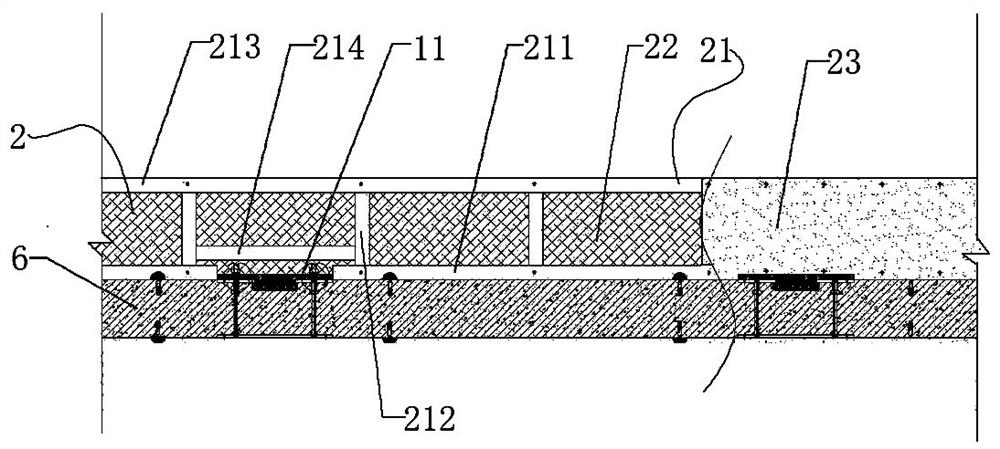

[0035] like figure 1 As shown, the curtain wall interlayer fireproof sealing structure based on the raised floor design of the present invention includes curtain wall connectors fixed on the edge of the floor 6, the sealing structure 2 on the keel arranged above the floor 6, and the lower sealing on the keel arranged below the floor 6. Blocking structure 3 and interlayer sealing structure; curtain wall connectors include curtain wall embedded parts 11 arranged on structural floor 6 and curtain wall platform code 1 fixed with curtain wall embedded parts 11, curtain wall embedded parts 11 along structural floor 6 The outer edge direction of the keel is evenly spaced; the sealing structure 2 on the keel and the sealing structure 3 under the keel are arranged along the edge of the floor 6, the distance between the sealing structure 2 on the keel and the edge of the floor 6 is 100-120mm, and the sealing structure under the keel 3 the outer edge is flush with the outer edge of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com