High-precision rotor for automobile VVT and manufacturing method of high-precision rotor

A high-precision, rotor technology, used in mechanical equipment, machines/engines, engine components, etc., can solve problems such as inability to meet the needs of use, complex product shapes, and bad proportions, achieving feasibility and economy, and simple structure. , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings.

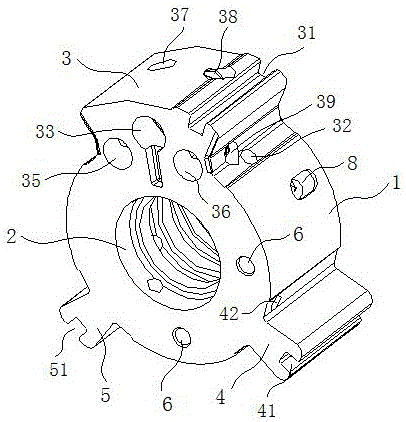

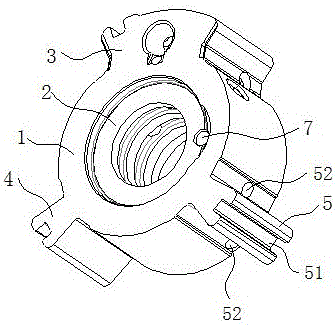

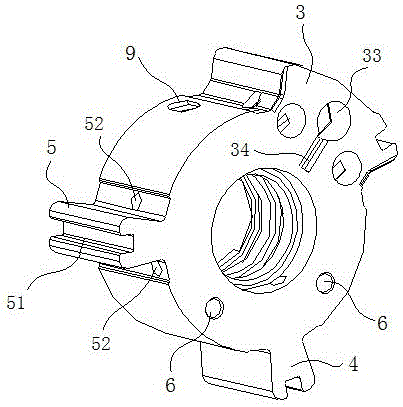

[0020] Such as figure 1 , figure 2 with image 3 As shown, the high-precision rotor for automobile VVT of the present invention is a component in the automobile VVT and is used to cooperate with the stator. The main structure of the rotor includes a cylinder 1 with a structure of a through hole 2, and lines are provided on the through hole 2. On the outer wall of the cylinder 1, there are first protruding ribs 3, second ribs 4 and third ribs 5 protruding outwards, wherein the arc width of the first ribs 3 and the second ribs 4 Similarly, the arc width of the third rib 5 is greater than that of the first rib 3, and axial grooves are arranged on the arc surfaces of the first rib 3, the second rib 4 and the third rib 5, respectively The first groove 31 , the second groove 41 and the third groove 51 . The cylinders 1 on both sides of the first rib 3 are provided with a f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com