Engine

An engine and pneumatic technology, applied in the direction of machines/engines, mechanical equipment, gas turbine devices, etc., can solve the problems of difficult to withstand high temperature, extremely high material requirements, affecting the thrust efficiency of aero-engines, and achieve a simple structure and high thrust efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

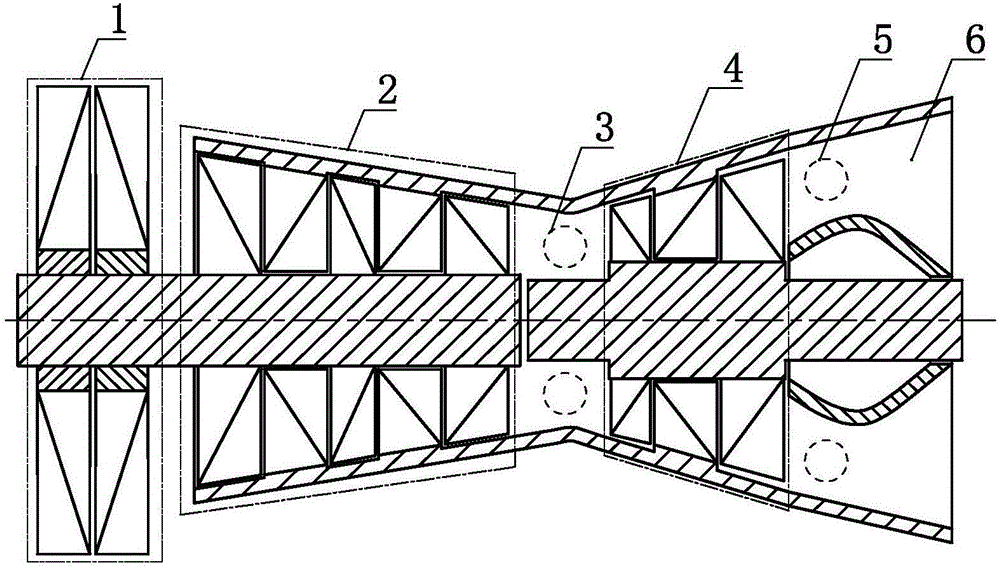

[0028] an engine such as figure 1 As shown, it includes a wind turbine 1, a compressor 2, a combustion chamber A 3, a turbine 4, a combustion chamber B 5 and a nozzle 6, the wind turbine 1 and the compressor 2 are set in transmission, and the The compressor 2 communicates with the turbine 4 via the combustion chamber A 3 , and the turbine 4 communicates with the nozzle 6 via the combustion chamber B 5 .

Embodiment 2

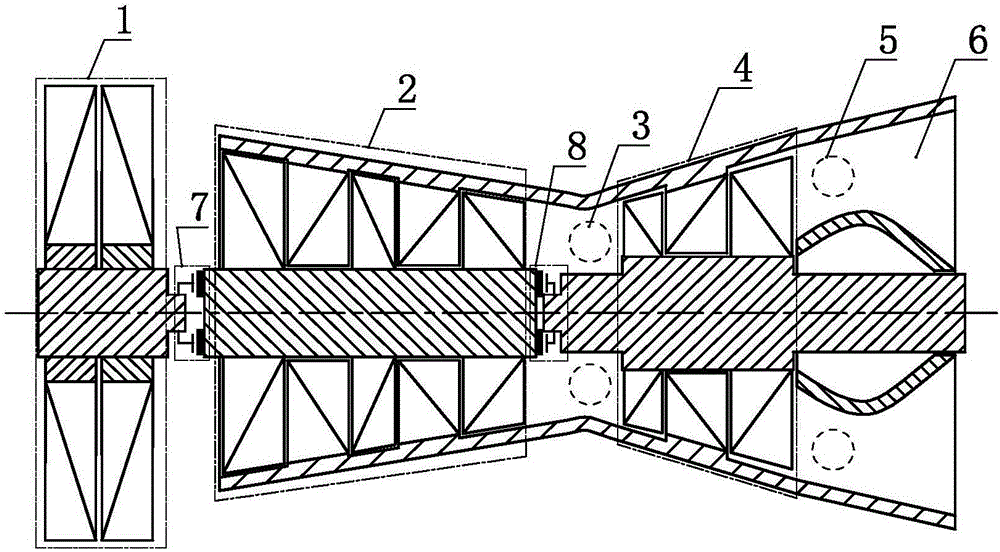

[0030] an engine such as figure 2 As shown, it includes wind turbine 1, compressor 2, combustion chamber A 3, turbine 4, combustion chamber B 5 and nozzle 6, and the compressor 2 is connected to the turbine 4 through the combustion chamber A 3 The turbine 4 communicates with the nozzle 6 through the combustion chamber B5, the wind turbine 1 is connected to the compressor 2 through the clutch A7, and the turbine 4 is connected through the clutch B 8 is set with the transmission of the compressor 2.

[0031] As a changeable embodiment, the present invention can also selectively select only the wind turbine 1 to be connected to the compressor 2 via the clutch A7, or only the turbine 4 to be connected to the compressor 2 via the clutch B8. The transmission setting of compressor 2 is described above.

Embodiment 3

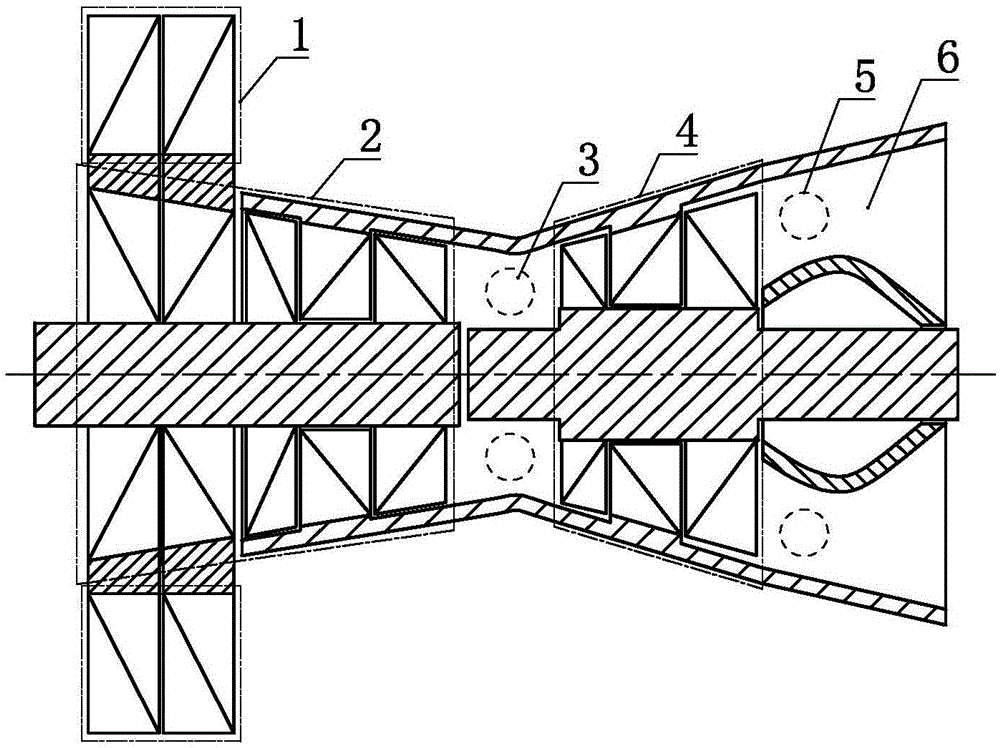

[0033] an engine such as image 3 As shown, it includes a wind turbine 1, a compressor 2, a combustion chamber A 3, a turbine 4, a combustion chamber B 5 and a nozzle 6, the wind turbine 1 and the compressor 2 are set in transmission, and the The compressor 2 communicates with the turbine 4 through the combustion chamber A 3, the turbine 4 communicates with the nozzle 6 through the combustion chamber B 5, the blade of the wind turbine 1 and the Part of the blades of the compressor 2 are radially co-bladed.

[0034] As a changeable implementation, Embodiment 3 of the present invention can further selectively select some or all of the blades of the compressor 2 that are radially co-bladed with the blades of the wind turbine 1 to communicate with the rest of the compressed air through the clutch A7. The blade transmission setting of the machine 2; and / or the transmission setting of the turbine 4 and the compressor 2 via the clutch B8.

[0035] As an alternative embodiment, in E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com