Pilot-operated blasting type pressure relief device

A pressure relief device and pilot-operated technology, which is applied in the direction of valve devices, functional valve types, safety valves, etc., can solve the problems of large deviation of opening pressure, inaccurate opening pressure, time-consuming, laborious and other problems, so as to avoid leakage problems and facilitate Observation, the effect of the overall compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

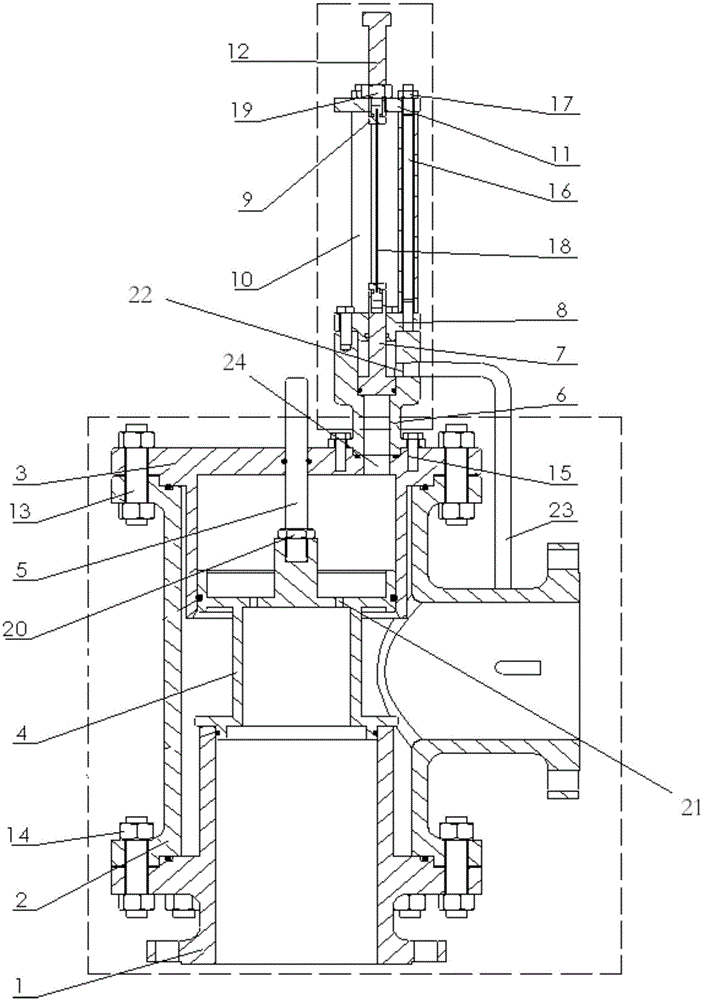

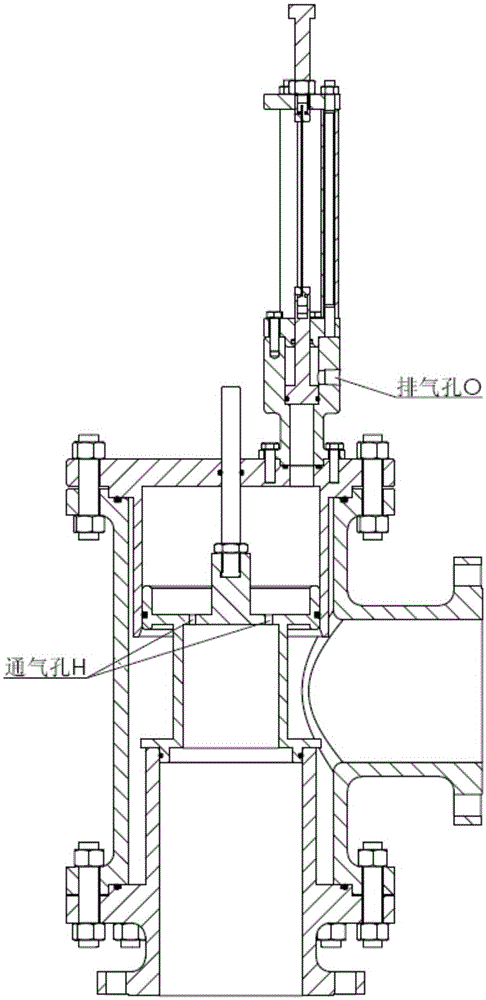

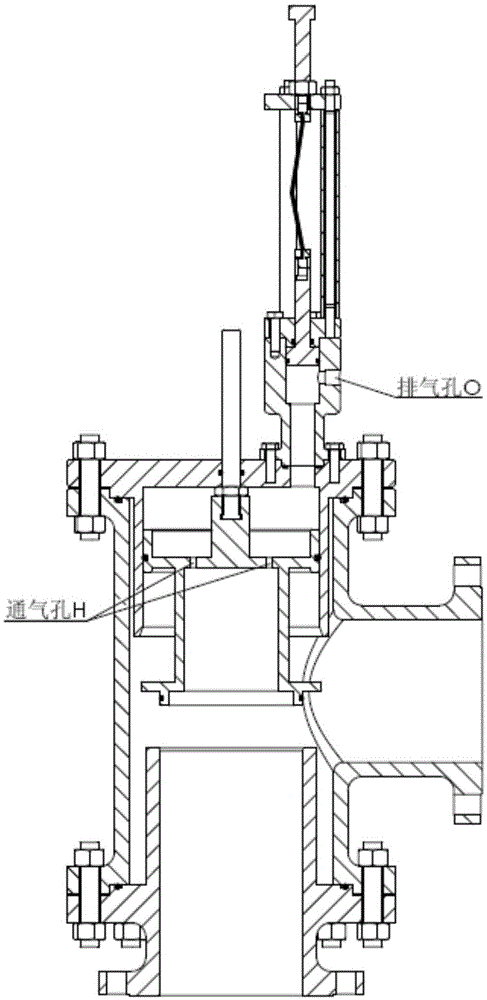

[0032] Such as figure 1 As shown, the pressure relief device is mainly composed of the main valve and the pilot valve. The main valve is composed of valve seat 1, valve disc 4, valve body 2, valve stem 5 and guide sleeve 3. Pilot valve is made up of pilot valve valve body 6, cover plate 8, pilot valve disc 7, depression bar 18, adjusting screw 12, sleeve 10, ferrule 9, pole 16, bracket cover 11.

[0033] The structure of the main valve is as follows: the lower end of the valve body 2 is fixedly installed on the flange of the valve seat 1, and is fixed by a stud 13 and a hex nut 14. A valve disc 4 is installed in the valve body 2, and the valve disc 4 is sealed and installed on the upper end of the valve seat 1. The upper end of the valve clack 4 is sealed and fixedly installed with the guide sleeve 3, and the upper end of the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com