A coke oven raw gas rising pipe heat exchange device

A raw gas and tube heat exchange technology, which is applied in the heating of coke ovens, the discharge device of retort gas, coke ovens, etc., can solve the problems of structural overheating, heat exchange medium retention, water consumption, etc., and achieve uniform distribution of thermal stress , It is not easy to be damaged by thermal stress, and the effect of preventing steam retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

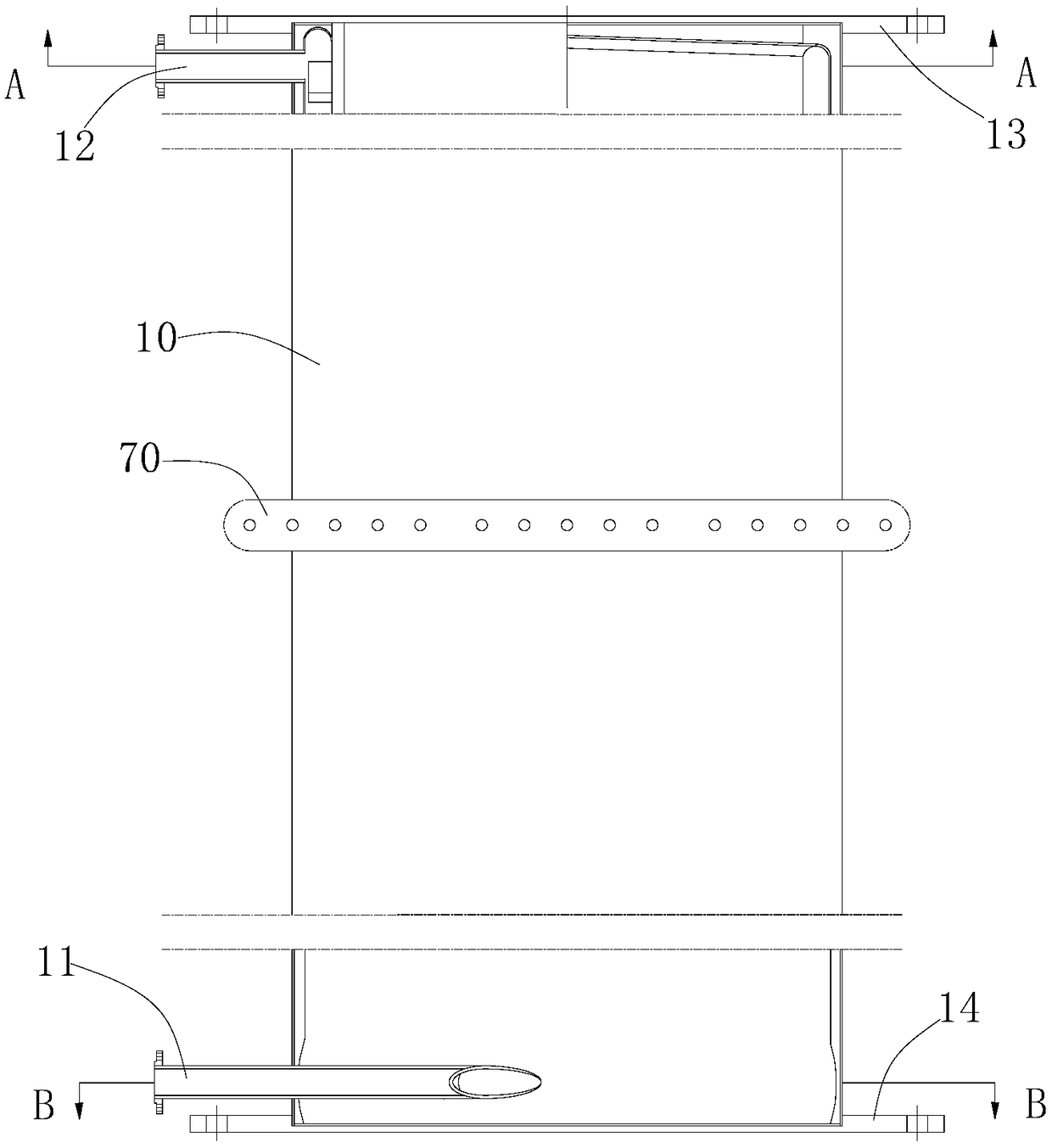

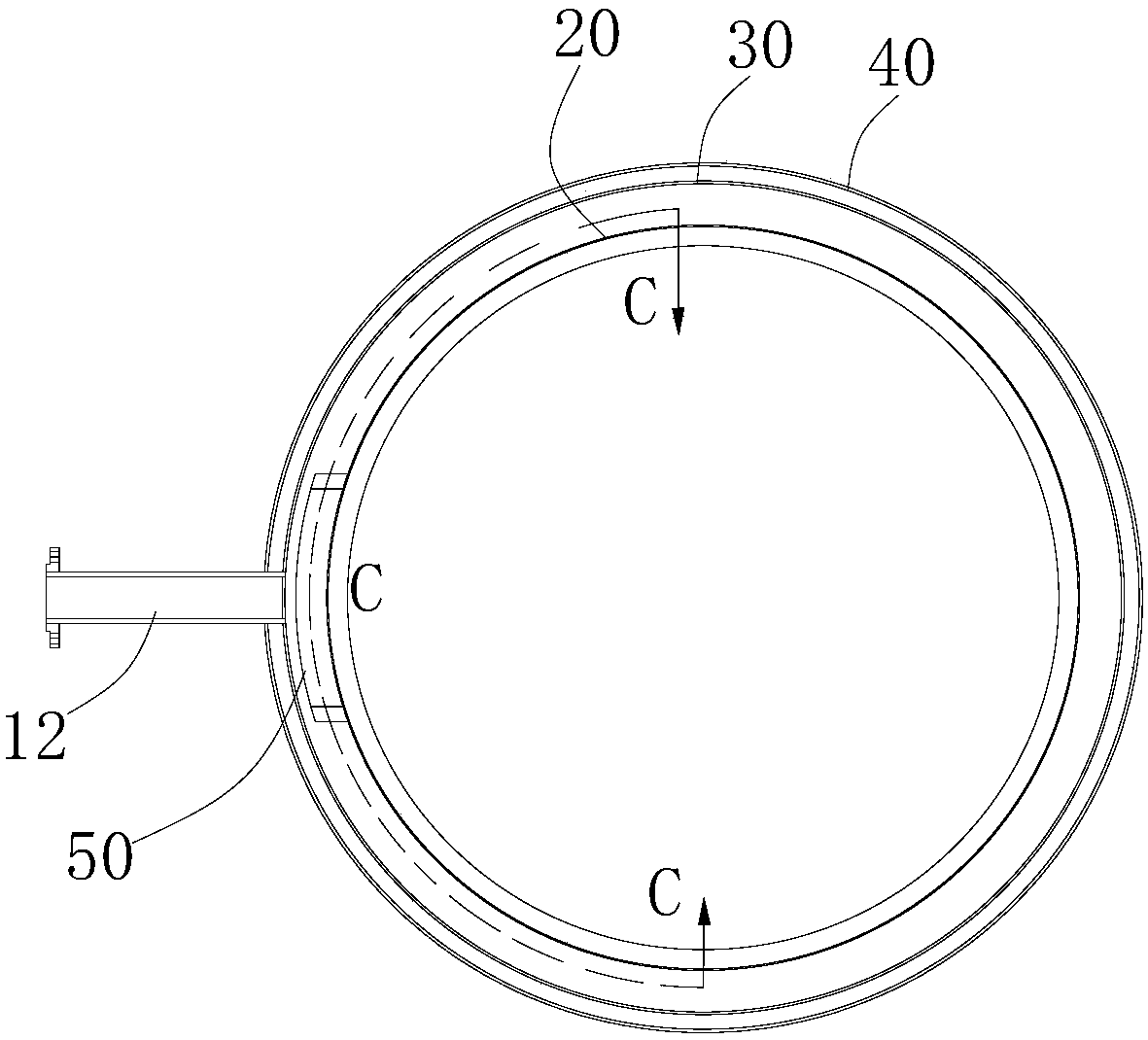

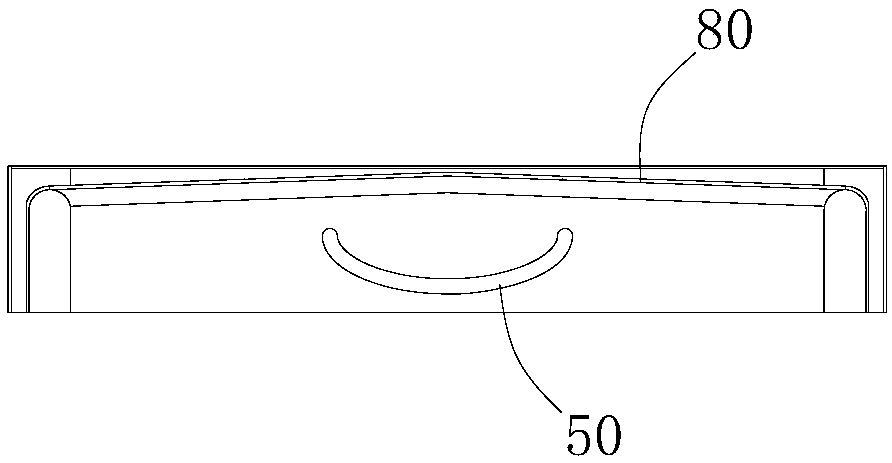

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this description, the principle of the present invention will be described through embodiments. Other aspects, features and advantages of the present invention will become clear at a glance through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

[0023] like Figure 1-5 As shown, a coke oven raw gas riser heat exchange device provided by an embodiment of the present invention includes a cylinder body 10, a heat exchange medium inlet pipe 11 disposed at the lower end of the cylinder body 10, and a heat exchange medium inlet pipe 11 disposed at the upper end of the cylinder body 10. The heat exchange medium outlet pipe 12, the cylinder body 10 sequentially includes an inner cylinder 20, a jacket sleeve 30 and an outer cylinder 40 from the inside to the outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com