A light emitting diode and its manufacturing method

A technology of light-emitting diodes and intrinsic semiconductors, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as the reduction of the radiation recombination probability of electrons and holes in the quantum well structure, the inability to dissipate the internal heat in time, and the reduction of the luminous efficiency of components. , to achieve the effect of improving the recombination efficiency of electron and hole radiation, increasing the luminous efficiency and prolonging the life of the LED

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

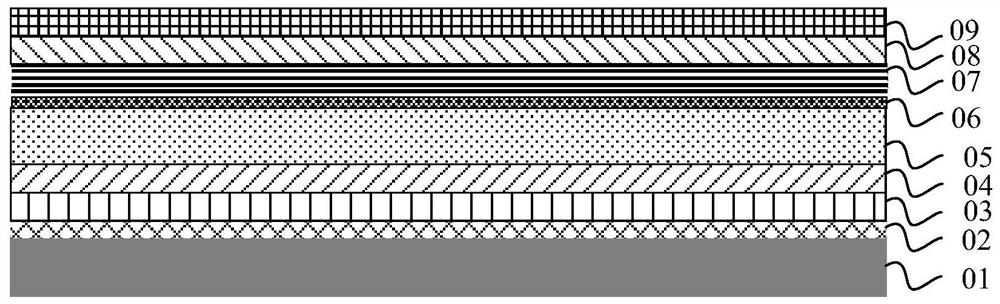

[0033] figure 1 It is a schematic diagram of the structure of a light-emitting diode in the prior art. Each epitaxial layer in the figure is a solid structure, and the heat generated during operation is difficult to dissipate. Generally speaking, whether the LED lamp works stably and its quality is good or bad is closely related to the heat dissipation of the lamp body itself. Importantly, the heat dissipation of high-brightness LED lamps on the market often adopts natural heat dissipation, specifically including aluminum heat dissipation fins, heat-conducting plastic shells, surface radiation treatment, aerodynamics, fans, heat pipes, liquid bulbs and other technologies, but the effect is not good. not ideal.

[0034] The heat is concentrated in the small-sized LED chip, and the temperature of the LED chip rises, causing non-uniform distribution of thermal stress, chip luminous efficiency and phosphor laser efficiency decrease; when the temperature exceeds a certain value, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com