Round paper sheet pressing-in device for combined fireworks

A technology of combining fireworks and pressing devices, applied in the directions of fireworks, offensive equipment, weapon types, etc., can solve the problems of low production efficiency, large labor load, uneven product quality, etc., and achieve high work efficiency, reliable work, and work. glitch-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

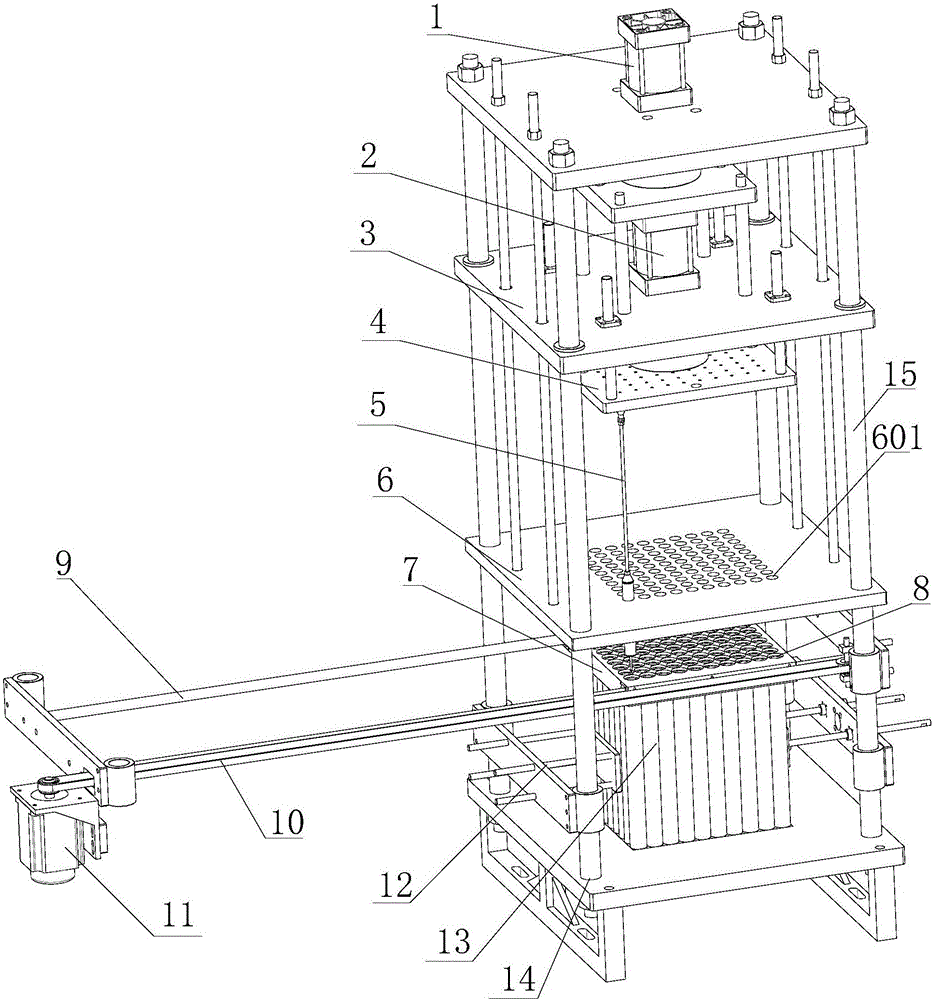

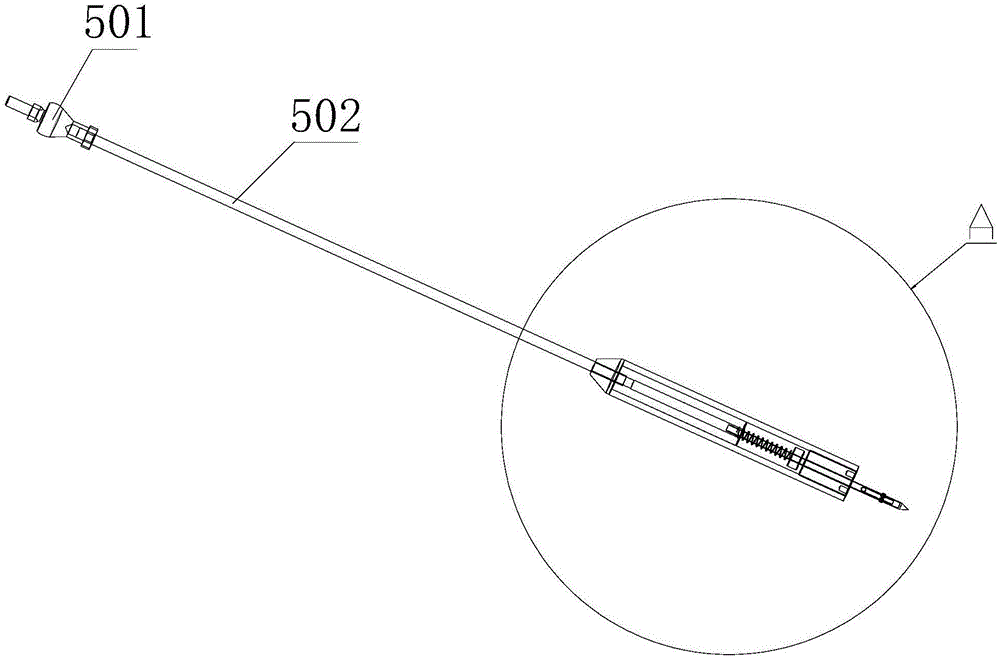

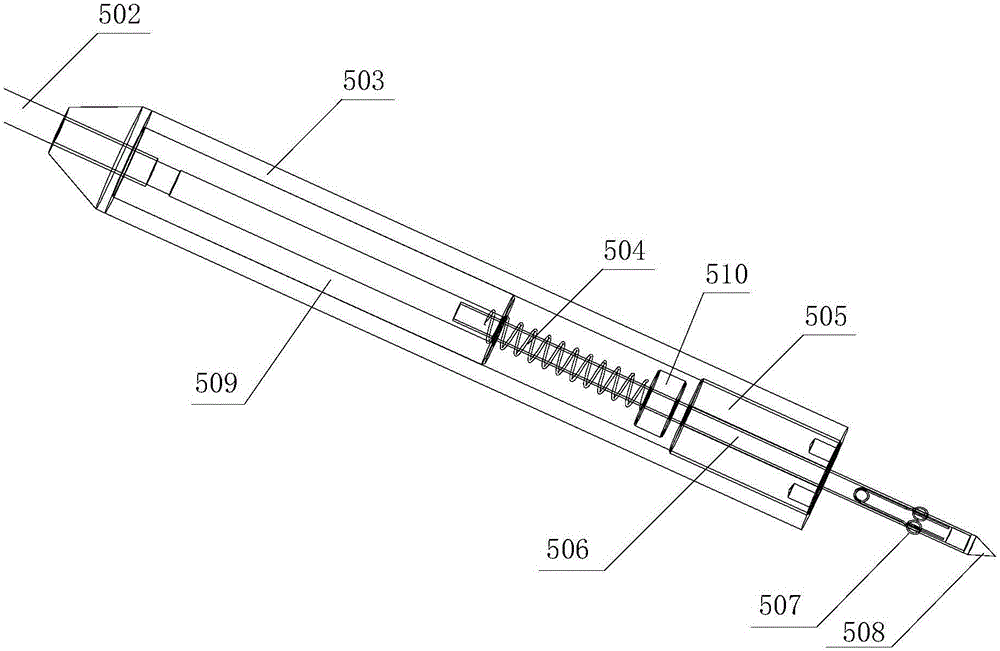

[0014] Embodiment 1: Referring to the accompanying drawings, it reflects a specific structure of the present invention, the paper bar pressing device for the combined fireworks completes the processing of one combined fireworks tube cake at a time. Including the frame 14, several paper fetching and pressing components 5 are hoisted under the first base plate 4 through the connecting rod 502, the top of the connecting rod 502 is connected to the first base plate 4 in a swingable manner through the hinge joint 501, and the first base plate 4 is connected to the first base plate 4. Drive the cylinder 2, the first drive cylinder 2 is installed on the second base plate 3, the second base plate 3 is installed on the guide column 15 and connected to the second drive cylinder 1; the device below the first base plate 4 is provided with a number of guide holes 601 Plate 6, each paper-fetching and pressing assembly 5 passes through the corresponding guide hole 601; a paper transfer plate ...

Embodiment 2

[0017] Embodiment 2: The difference from Embodiment 1 lies in the structure of the elastic clip. see Figure 5 . The elastic clip 102 is installed in the needle bar 101 . The arc section of the elastic clip 102 protrudes from the side of the needle bar 101 . Its function can also be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com