Fiber grating displacement meter in fiber grating series mode

A fiber grating string, fiber grating technology, which is applied in the direction of using optical devices, instruments, measuring devices, etc., can solve the problems that continuous measurement cannot be performed, only horizontal displacement can be measured, and only vertical displacement can be measured, and the preparation and maintenance can be achieved. Low cost, easy to operate, and good for production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

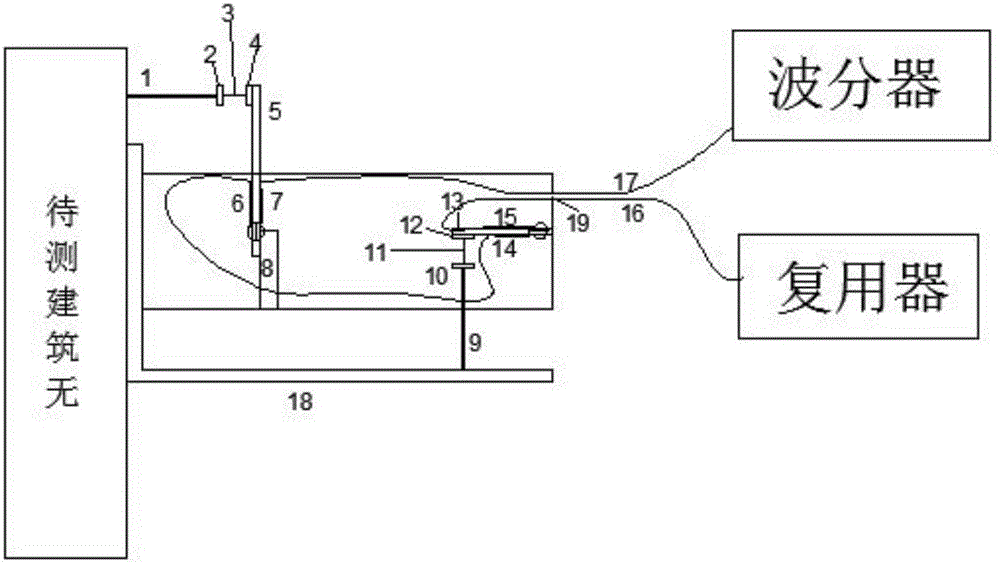

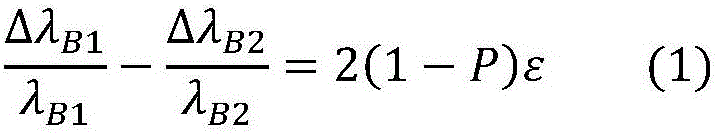

[0027] The main structure of this embodiment is the first probe rod 1, the first pad 2, the first spring 3, the second pad 4, the equal strength beam 5, the first fiber grating 6, the second fiber grating 7, and the third pad 8. The second probe rod 9, the fourth spacer 10, the second spring 11, the fifth spacer 12, the cantilever beam 13, the third fiber Bragg grating 14, the fourth fiber Bragg grating 15, the first pigtail 16, the second tail fiber 17, displacement meter fixing device 18 and housing opening 19; the first spacer 2 and the second spacer 4 are fixed on the displacement meter housing, and the two ends of the first spring 3 are fixedly installed with the first spacer 2 and the first spacer respectively. The second spacer 4, the first spring 3 is equipped with one end of the second spacer 4 and is fixed on the equal strength beam 5, and the other end is connected with the first probe rod 1, and the first probe rod 1 is connected with the building to be measured, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com