Liquid crystal display panel

A liquid crystal display panel and display area technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of being unable to stop the edge diffusion of the frame glue, uneven diffusion speed resistance, and fluctuations in the edge diffusion of the frame glue, so as to avoid display Poor effect, reduce the risk of liquid crystal puncture, improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

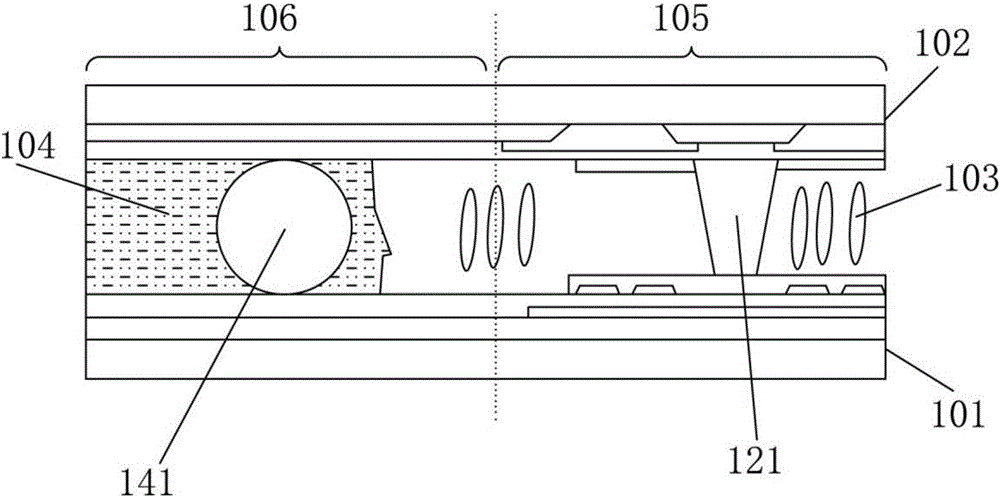

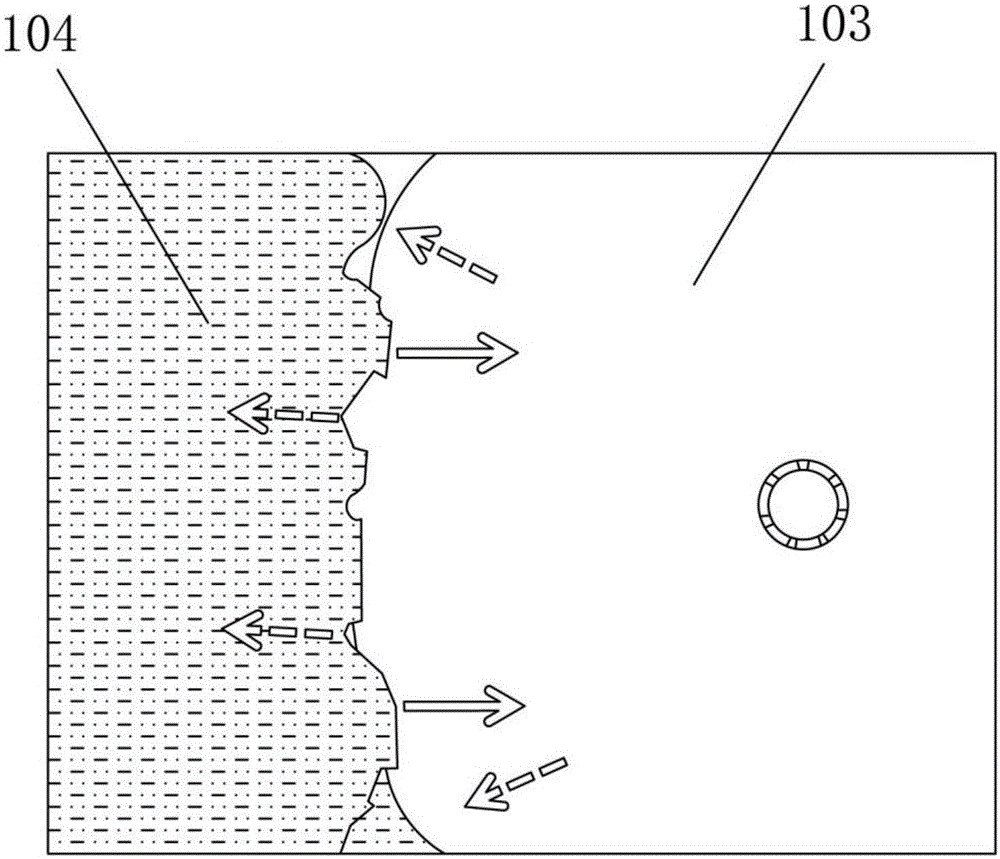

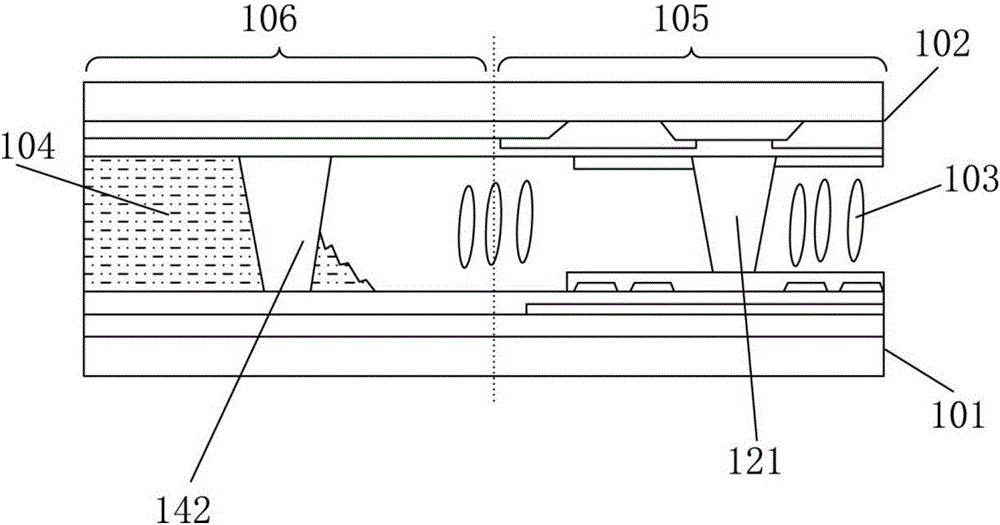

[0057] Such as Figure 4 and Figure 5 as shown, Figure 4 It is a schematic cross-sectional structure diagram of a liquid crystal display panel shown in an embodiment of the present invention; Figure 5 It is a top view of the liquid crystal display panel shown in the embodiment of the present invention to limit the diffusion of the sealant and the puncture of the liquid crystal; the liquid crystal display panel of the present embodiment includes a first substrate 401, a second substrate 402, and a The liquid crystal display panel further includes a display area 403 and a non-display area 404 . The sealant 441 is located in the non-display area 404 and is arranged around the display area 403 . The liquid crystal display panel also includes a first groove 411, a second groove 412, a first spacer 421, and a second spacer 422, the groove wall of the first groove 411 and the groove wall of the second groove 412 A protrusion is formed; wherein, the first groove 411 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com