Patents

Literature

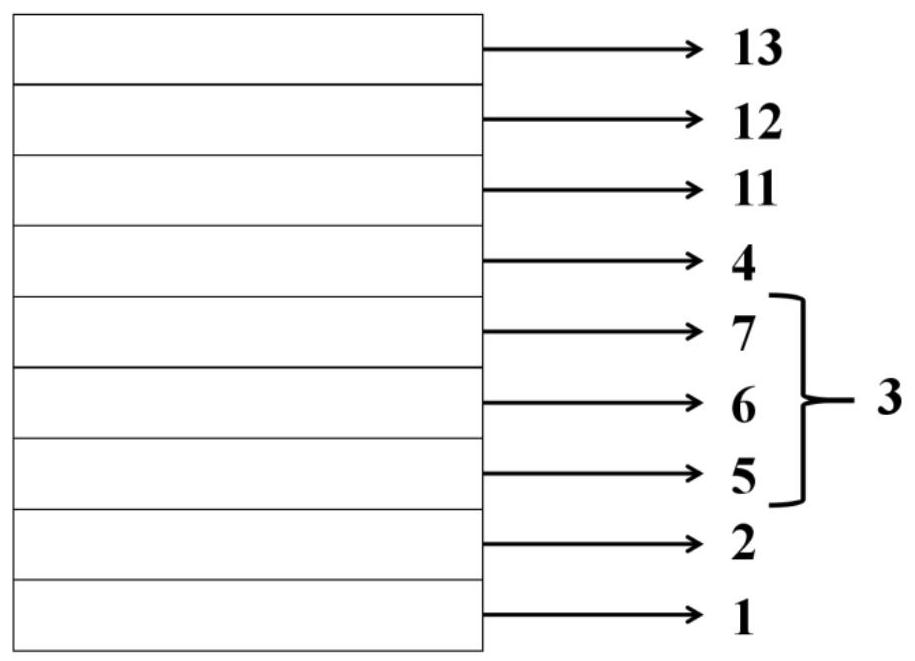

43results about How to "No dark spots" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

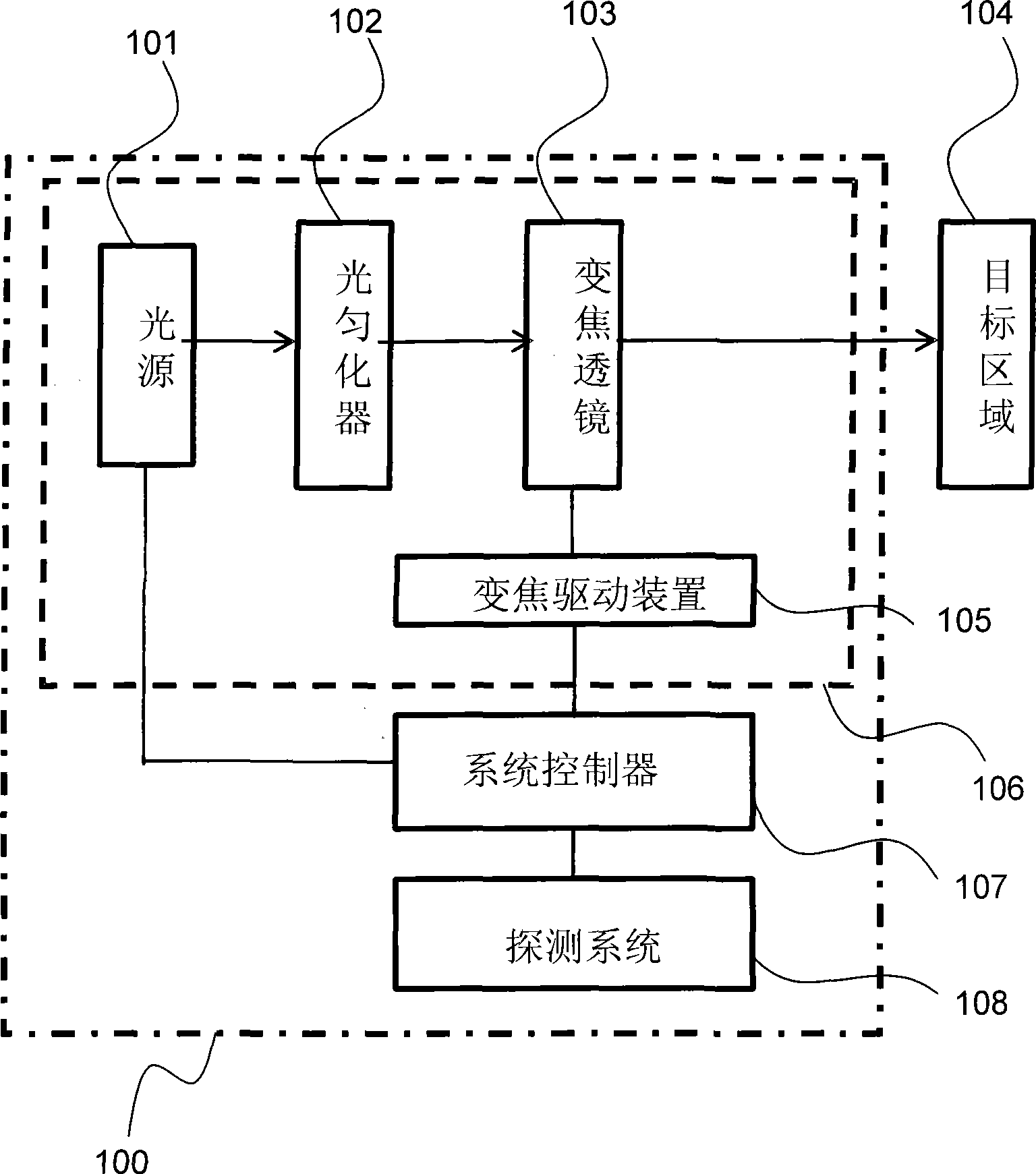

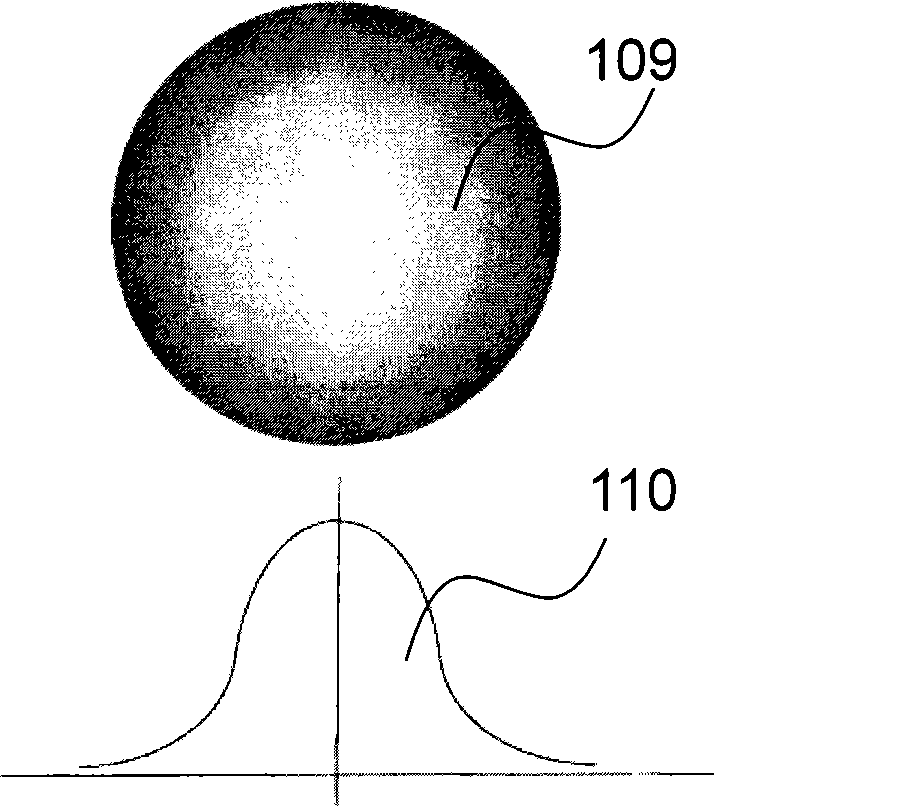

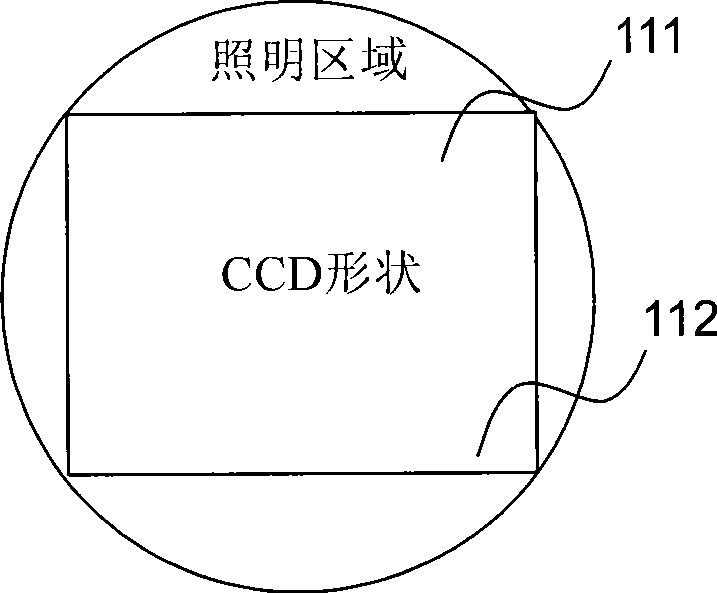

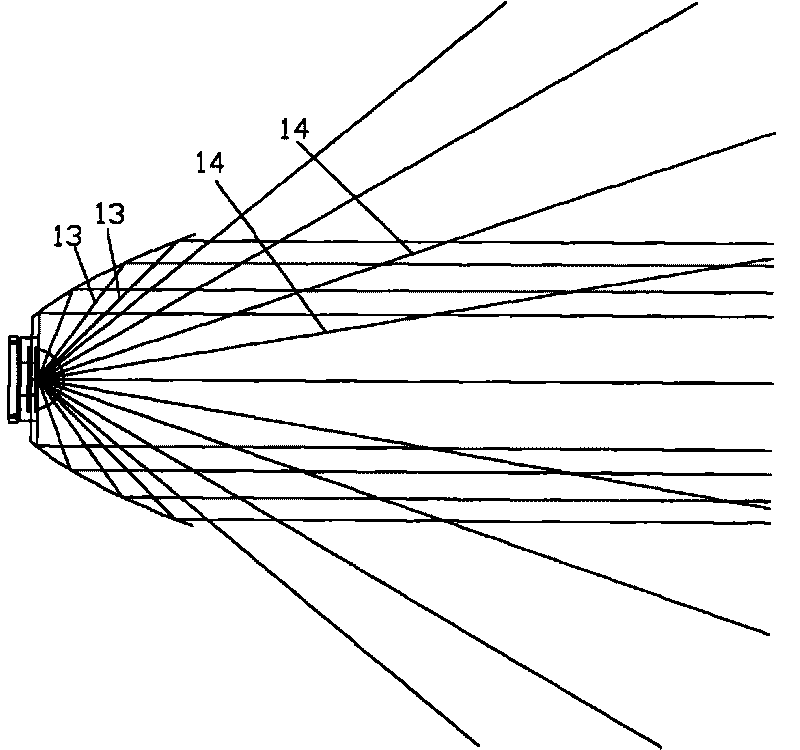

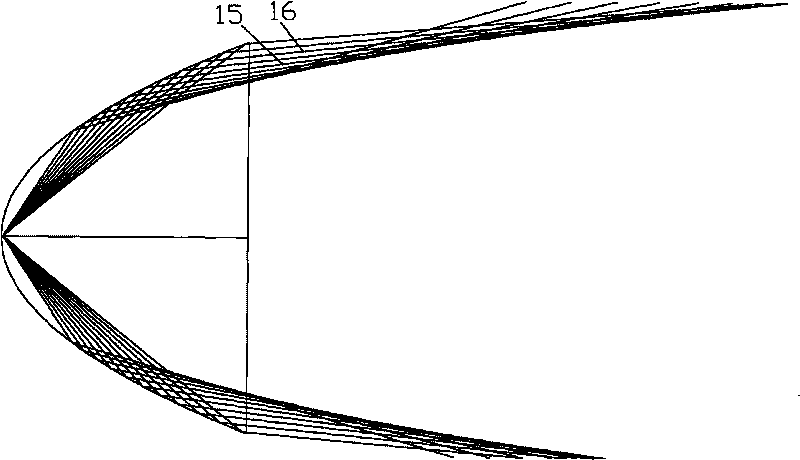

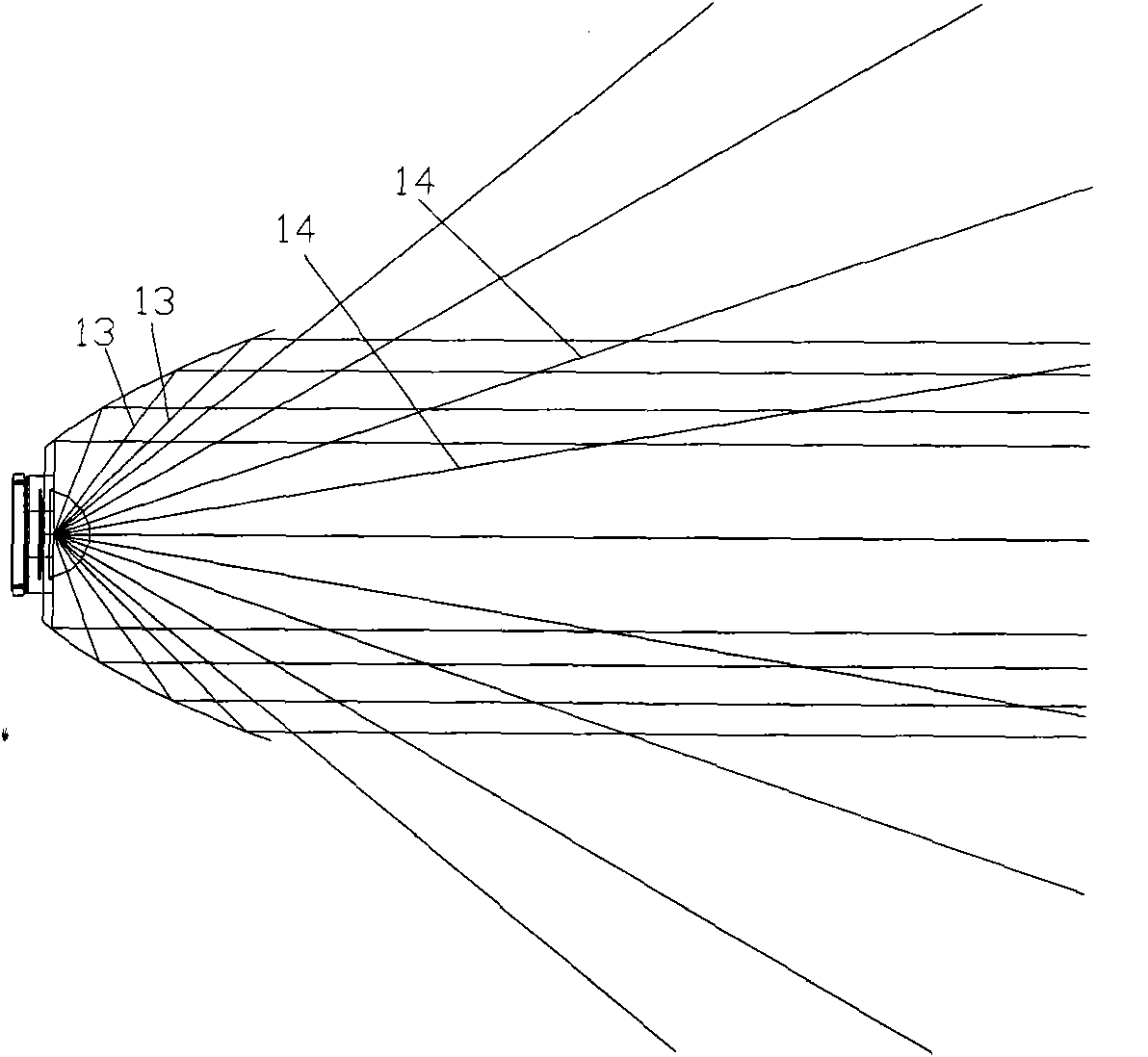

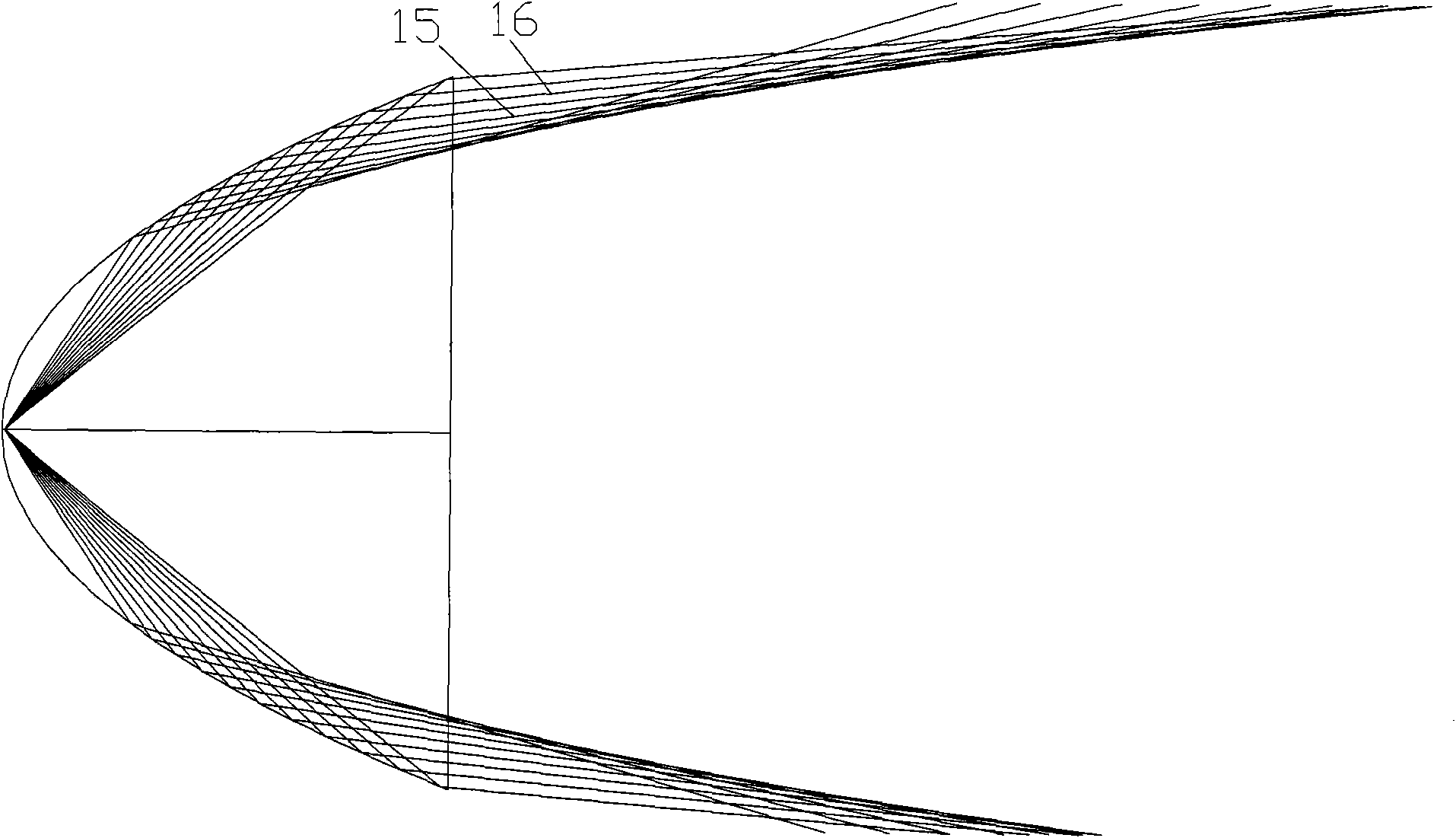

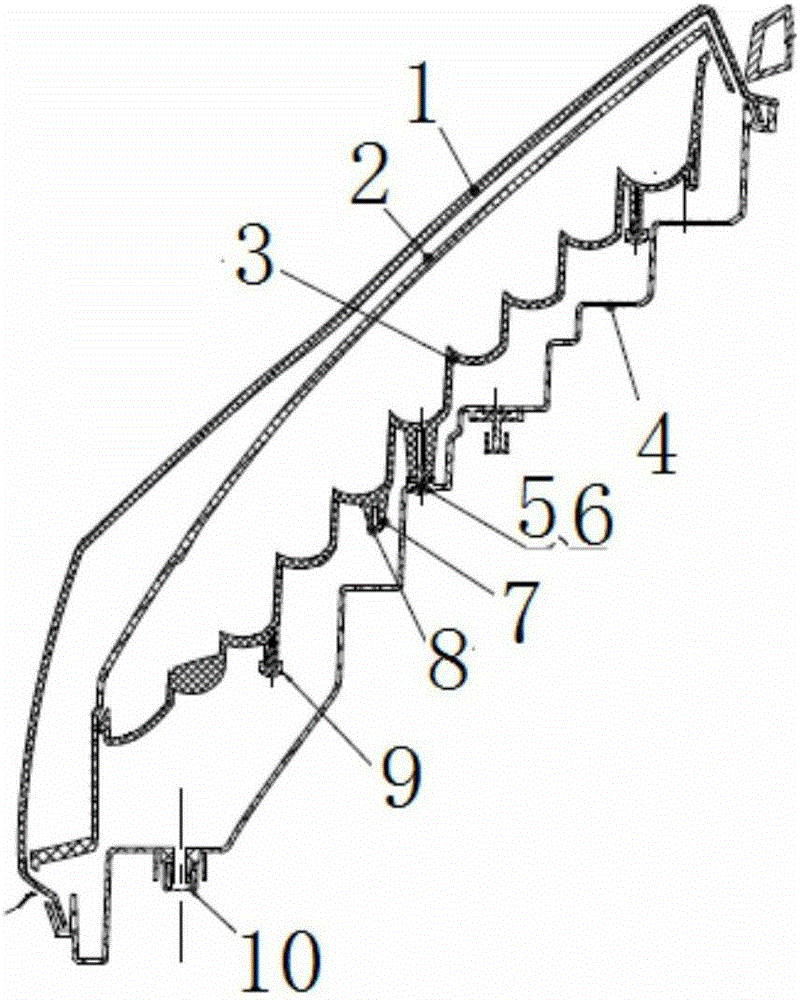

Uniform high-efficiency lighting system used in night viewing system

InactiveCN101477242AUniform lightingClear imagingTelescopesMountingsRelative displacementLighting system

The invention discloses an illuminating system applied to a night-vision system, which comprises a light source, a zoom lens group and a zoom driving device, wherein the zoom driving device is connected with the zoom lens group and / or the light source and used for making lenses in the zoom lens group generate relative displacement to the light source so as to change the focus distance of the zoom lens group, and a light emergent surface of the light source is positioned on a focus of the zoom lens group or outside the focus. The illuminating angle of the illuminating system can be adjusted on a large scale along with the change of the lens focus distance by changing the focus distance of the lens group. The illuminating system has even illumination, which can make the imaging clear, without dark space; and the illuminating system can effectively improve light utilization rate and reduce luminous energy loss.

Owner:郑维彦

Polyvinylchloride (PVC) plastic wood plank and preparation method thereof

The invention provides a polyvinylchloride (PVC) plastic wood plank and a preparation method thereof. The PVC plastic wood plank consists of the following ingredients: PVC, calcium carbonate, wood flour, azodicarbonamide (AC) foaming agents, stabilizing agents, coupling agents, acrylicester (ACR), paraffin wax, stearic acid and fire retardants. By means of the PVC plastic wood plank, appending proportion of the calcium carbonate is enhanced by reducing the amount of the wood flour, and at the same time, by adjusting the amount of the PVC, and the type and amount of other additives, not only can hardness of the plank be greatly enhanced, but also appropriate toughness can be possessed. Therefore, the plank is guaranteed to be not only possess enough hardness when used as wood floors in public places so that damage and sinking of the surface of the plank are not prone to occurring, but also meet requirements of the wood floors due to the toughness of the plank so that the plank can be ensured to be not easy to crack.

Owner:江西铁木真装饰材料有限公司

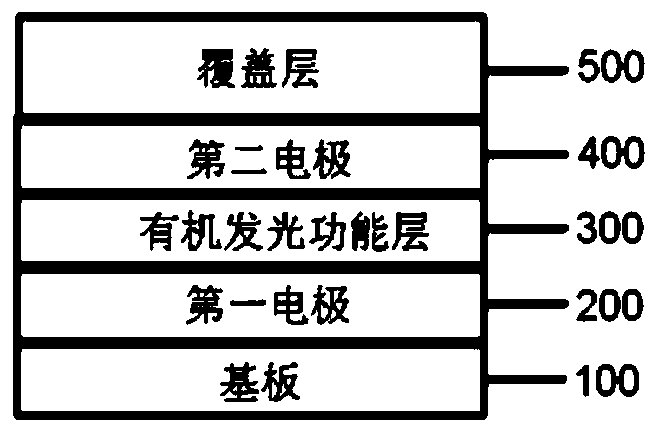

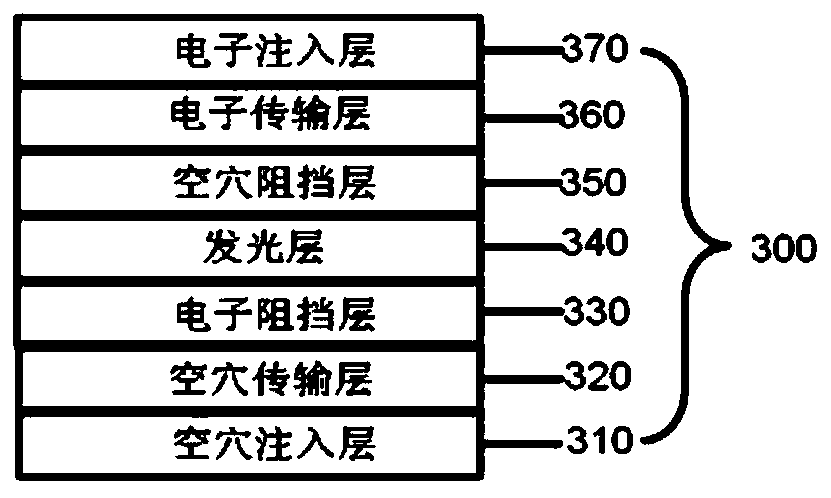

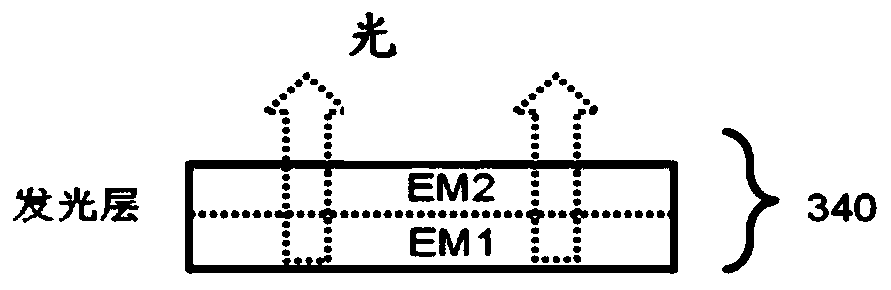

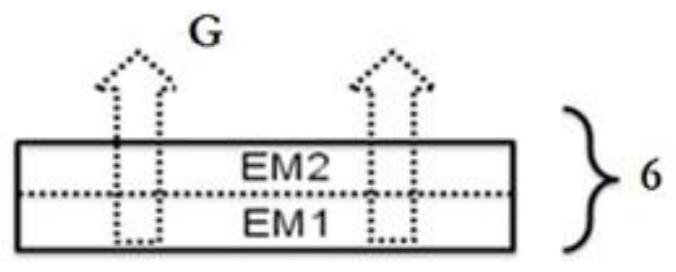

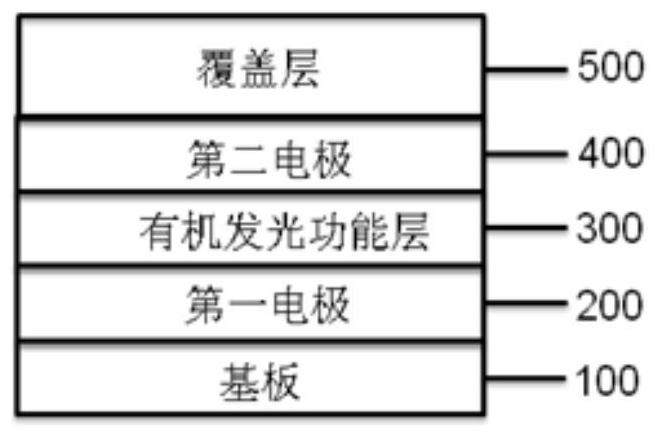

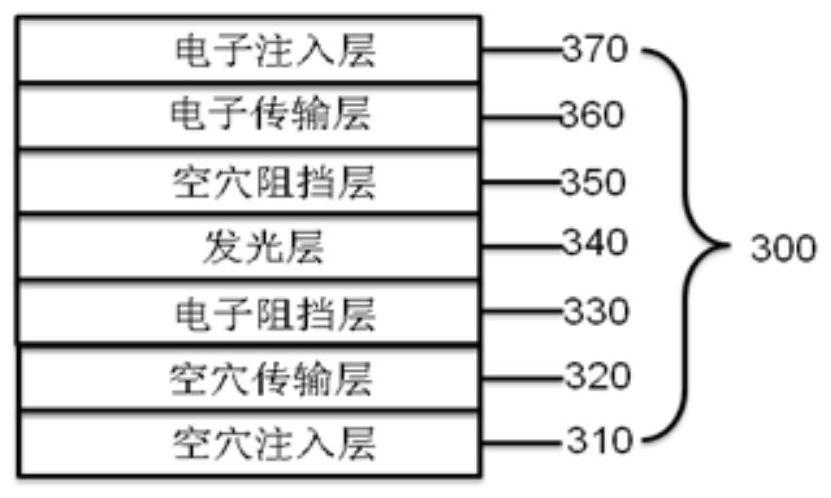

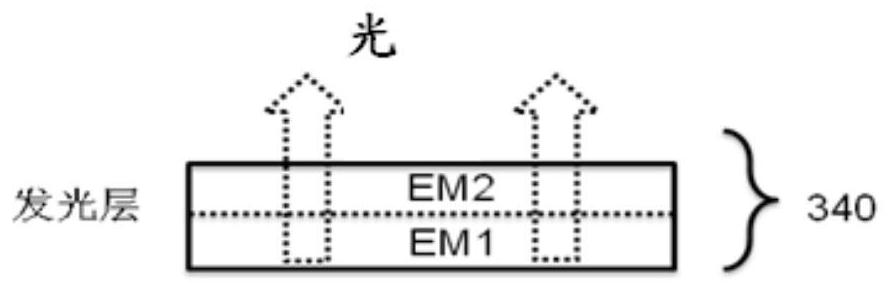

Organic electroluminescent device containing capping layer and application thereof

ActiveCN109860425AImprove light extraction efficiencyExcellent viewing angleSolid-state devicesSemiconductor/solid-state device manufacturingSimple Organic CompoundsLight equipment

The invention relates to an organic electroluminescent device containing a capping layer. The organic electroluminescent device containing the capping layer comprises a substrate layer, a first electrode, an organic light emitting functional layer, a second electrode and the capping layer, wherein the first electrode is located on the substrate; the organic light emitting functional layer is located on the first electrode; the second electrode is located on the organic light emitting functional layer; and the capping layer is located on the second electrode, the capping layer comprises an organic compound, the organic compound of the capping layer contains different types of heteroarylamines and has higher glass transition temperature and molecular thermal stability. Low absorption and high refractive index in the visible light field are achieved, and the light extraction efficiency of an OLED device can be effectively improved after the organic electroluminescent device is applied toa CPL layer of an organic light Emission diode (OLED) device. The invention further relates to the application of the organic electroluminescent device containing the capping layer for display or lighting equipment.

Owner:JIANGSU SUNERA TECH CO LTD

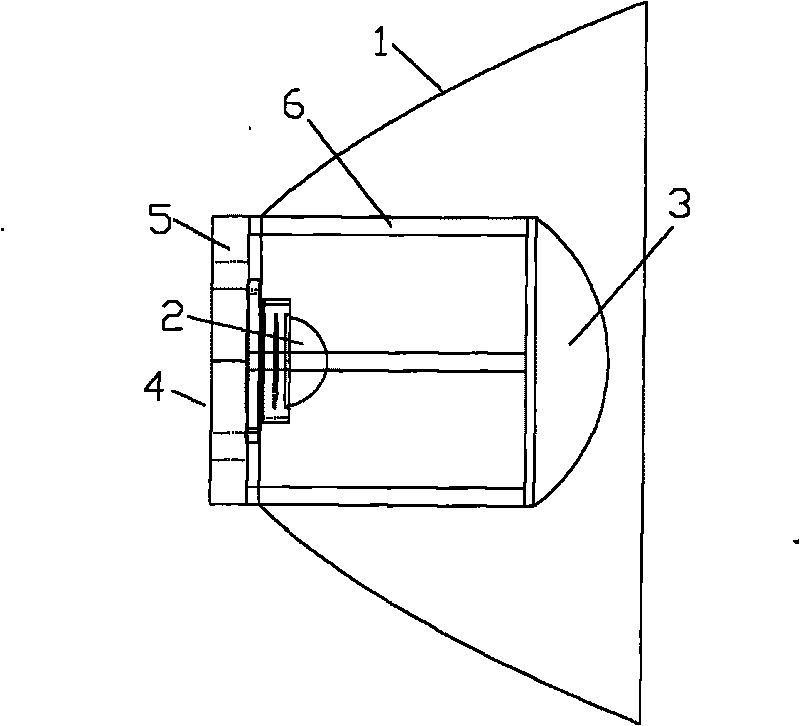

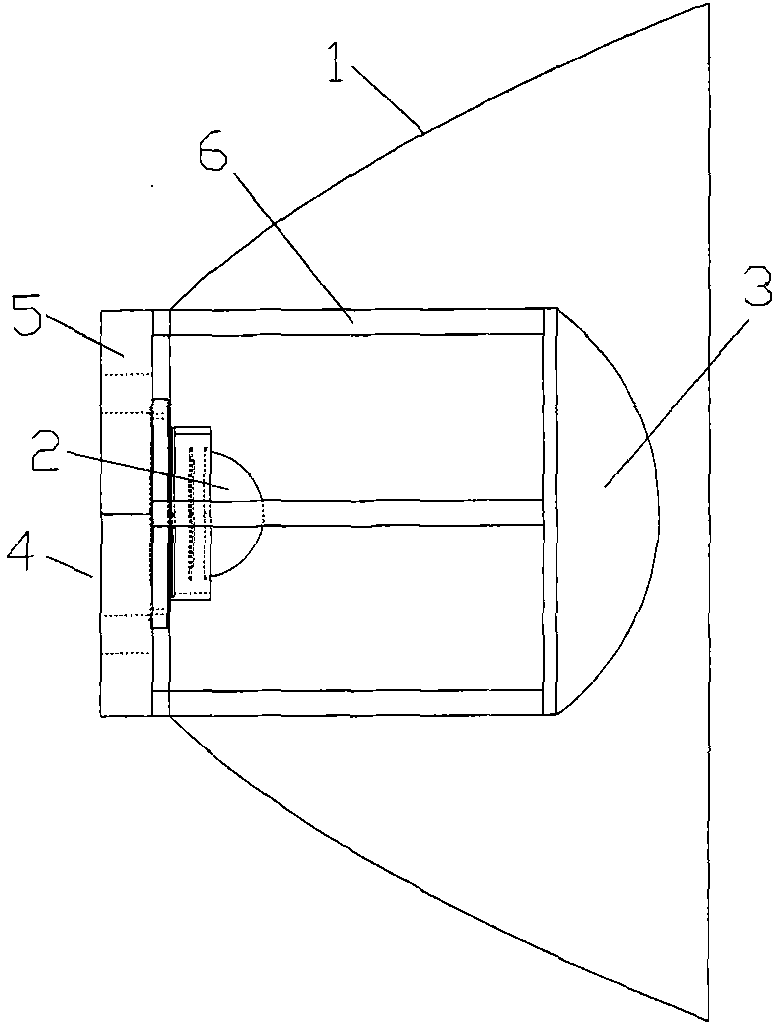

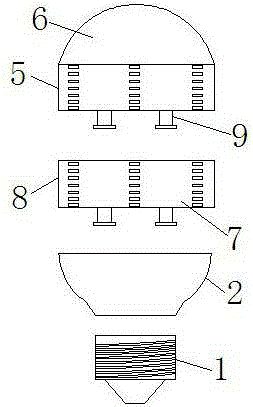

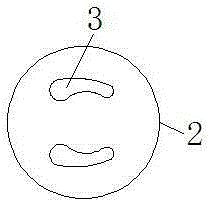

LED light focusing and flooding lamp

InactiveCN101709833AIncrease light intensityHigh luminous flux utilizationPoint-like light sourceElectric lightingDark spotEngineering

The invention provides an LED light focusing and flooding lamp which is suitable for the fixed or the movable illumination of the electric torch, the head lamp and the like. The LED light focusing and flooding lamp comprises a reflector (1) and an LED (2), wherein the LED (2) is arranged in the reflector (1), the front of the LED (2) is provided with a lens (3), and the lens (3) is arranged on an adjustable lens support (4) which can move along the main optical axis of the LED (2). When focusing the light, the LED light focusing and flooding lamp can ensure that the center of the light spot has high light intensity and high luminous flux utilization ratio, and when flooding the light, the LED light focusing and flooding lamp can ensure that no dark spot appears in the center of the light spot and the illumination of the light spot in the center is uniform.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Freeze-drying technology of bletilla striata vacuum freeze-drying

PendingCN109520213AAvoid the loss of active ingredientsImprove crushing rateDrying solid materials without heatRefrigeration temperatureFreeze dry

The invention provides a freeze-drying technology of bletilla striata vacuum freeze-drying, and relates to the field of bletilla striata processing. The freeze-drying technology comprises the following steps of pre-freezing: putting bletilla striata in a vacuum freeze-drying machine, cooling bletilla striata to be minus 30 DEG C or below, and maintaining the temperature for 3 h to 4 h; and vacuumdrying: starting a cold trap refrigeration mode, controlling refrigeration temperature of a cold trap device to be minus 60 DEG C or below, maintaining the vacuum degree to be 30 Pa or below, and carrying out drying treatment. According to the freeze-drying technology of bletilla striata vacuum freeze-drying provided by the invention, effective components of fresh bletilla striata can be remainedto the greatest extent, freeze-dried bletilla striata are beautiful in section and loose in structure, and can be directly smashed, the smashing rate is high, the dissolution rate is high during decoction, storage time of freeze-dried bletilla striata is prolonged, and mass is light.

Owner:九信(武汉)中药研究院有限公司

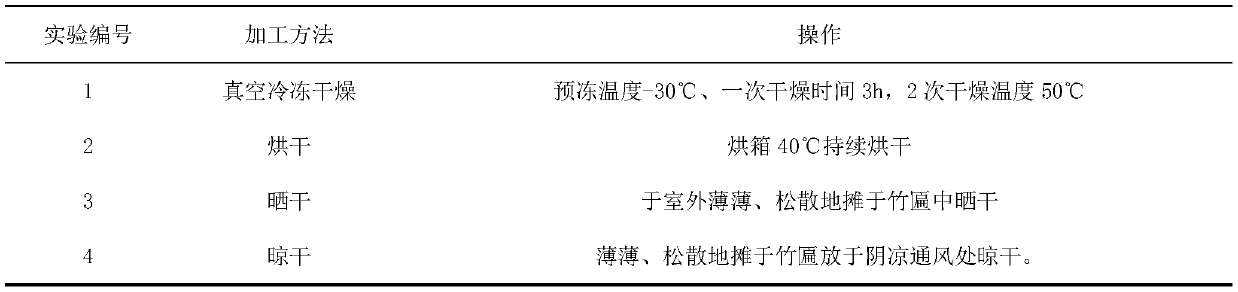

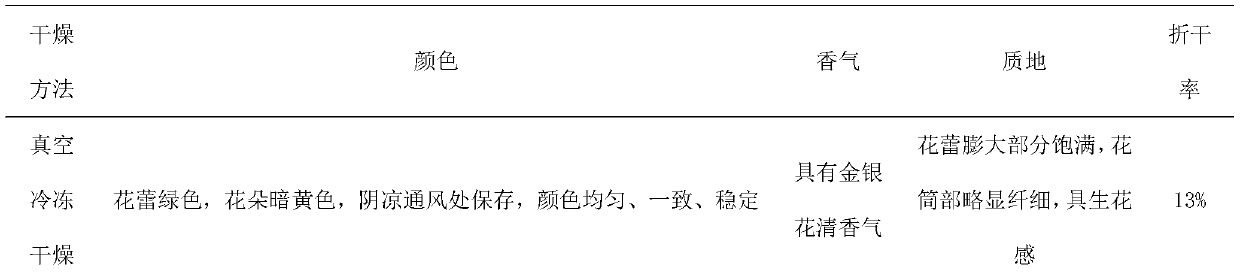

Honeysuckle vacuum freeze drying process

ActiveCN111494449AInhibit oxidative decompositionReduce vacuum freeze drying timeDrying solid materials without heatPlant ingredientsOrganic acidChlorogenic acid

The invention relates to the technical field of honeysuckle processing, in particular to a honeysuckle vacuum freeze-drying process which comprises the steps of: pretreatment, placement of raw materials on plates, pre-freezing and vacuum drying. According to the method, an advanced quick-freezing method is utilized, so that the vacuum freeze-drying time is shortened, the energy consumption is reduced, and substances are prevented from being continuously oxidized and decomposed under the action of enzymes in the drying process. The process for processing honeysuckle by vacuum freeze drying is researched for the first time, wherein the process parameters are optimized, so that the heat of supplied materials is minimum, the sublimated water is fastest, the drying time is shortest, the energyconsumed for removing unit mass of water is minimum, and the quality of dried products is best. Components such as organic acids, flavonoids, volatile oils, saponins and the like in the honeysuckle obtained by the method are higher than those of honeysuckle obtained by other methods, the content of chlorogenic acid is 3.19%, and the vacuum freeze drying technology has obvious advantages in the aspect of protecting poor heat sensitivity and volatile components.

Owner:SHANDONG UNIV OF TRADITIONAL CHINESE MEDICINE

Thick broad-bean sauce and preparation method thereof

InactiveCN106722204APromote growthUniform colorFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentFlavorNutritive values

The invention relates to the field of food processing, and particularly provides thick broad-bean sauce and a preparation method thereof. The preparation method of the thick broad-bean sauce comprises the following steps that 1, ginger is fermented, wherein the ginger is blended and pickled with salt and wine, and semi-finished ginger is obtained through natural fermentation; 2, peppers are fermented, wherein the peppers are mixed with salt, wine and spices are added, and after drying and exposing are carried out, semi-finished peppers are obtained through fermentation; 3, beans are fermented, wherein the peeled beans are dried after being soaked to expand, flour is added, the materials are mixed to be uniform, the mixture is naturally inoculated for starter propagation, the beans are soaked with brine after being dried, and after drying and exposing are carried out, semi-finished bean halves are obtained through fermentation; 4, the semi-finished ginger, the semi-finished peppers and the semi-finished ginger bean halves obtained in the step 1, the step 2 and the step 3 respectively, optional wine, optional spices and optional Chinese herbal medicine are mixed to be uniform, and the thick broad-bean sauce is obtained. The thick broad-bean sauce prepared through the method has the advantages of being good in product flavor, even in color and luster and high in nutritive value.

Owner:刘云

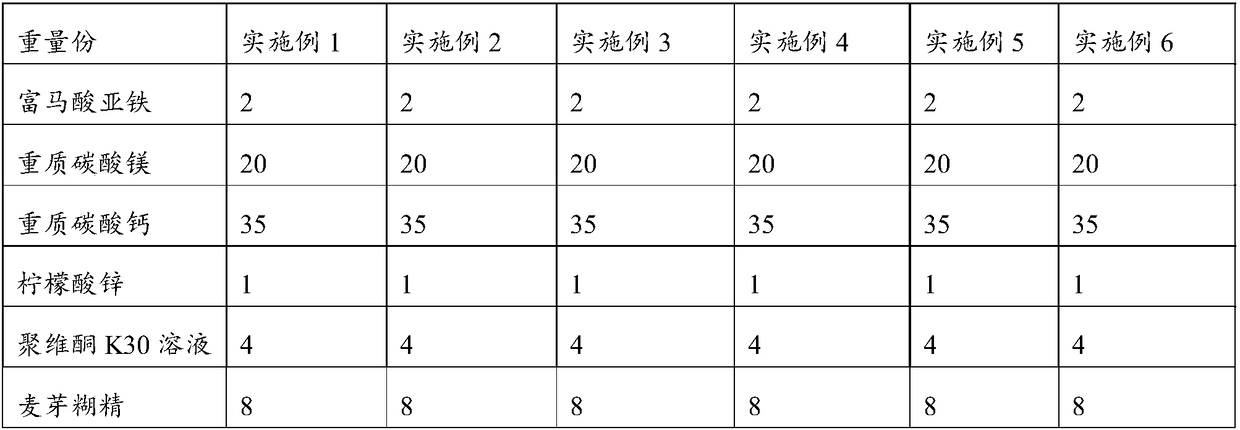

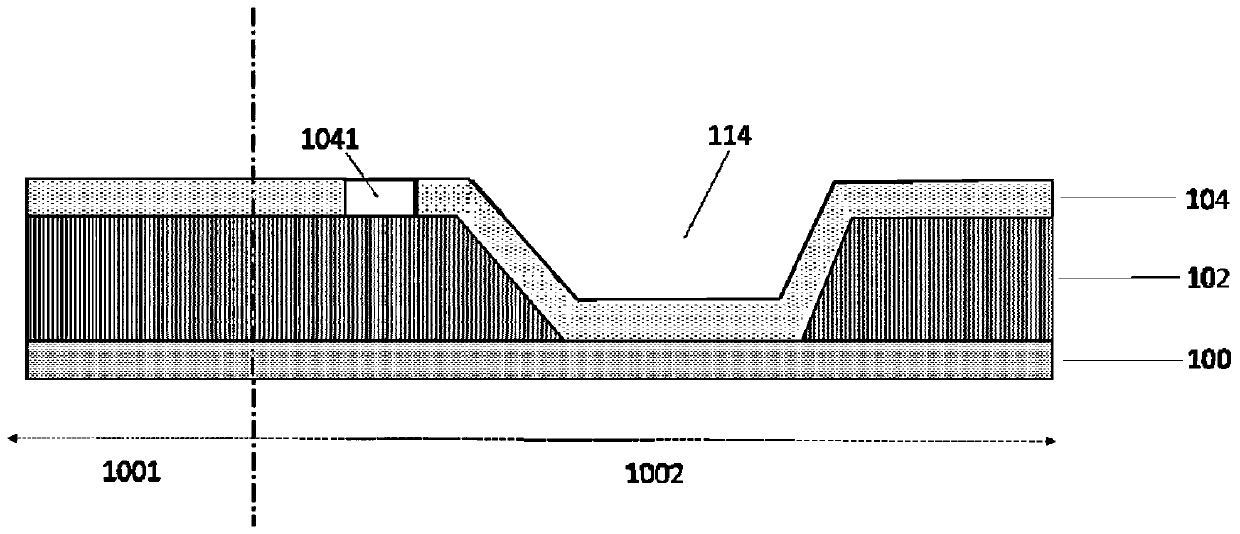

Vitamin mineral matter tablet, and preparation method thereof

InactiveCN109288803AImprove stabilityImproves Ascorbic Acid StabilityHeavy metal active ingredientsVitamin food ingredientsVitamin K2Vitamin C

The invention belongs to the technical field of health care product, and especially relates to a vitamin mineral matter tablet, and a preparation method thereof. The vitamin mineral matter tablet is mainly composed of a tablet core and a film coating agent; the tablet core comprises, by weight, at least one or a plurality of metals selected from iron, magnesium, zinc, and calcium, at least one vitamin or a plurality of vitamins selected from vitamin C, vitamin C sodium, vitamin E, vitamin A, vitamin B1, vitamin B2, vitamin B3, vitamin B5, vitamin B6, vitamin B12, vitamin D3, vitamin K, folic acid, and vitamin H; and an auxiliary agent; and the mass amount of the vitamin C sodium accounts for 40 to 100% of the total mass amount of vitamin C and vitamin C sodium. The vitamin mineral matter tablet is capable of solving problems in the prior art that conventional vitamin mineral matter tablet is poor in stability, chemical interacting effect is easily caused, efficiency is influenced, andcomposition yellowing or generation of black spots is caused.

Owner:BY HEALTH CO LTD

Polished tiles pulverizing technology

The invention discloses a polished tiles pulverizing technology. The polished tiles pulverizing technology comprises the following steps: 1) preparing a material; 2) burdening: according to the production requirement and process requirement, proportioning the raw material and feeding the raw material; 3) performing ball-milling: through a ball-milling medium of ballstone, grinding the raw material to a slurry, wherein the fineness, moisture and liquidity of the process requirements can be reached; 4) sieving: removing the rough particles and impurities; 5) removing iron: removing iron which can influence the whiteness of the bricks in the slurry; 6) homogenizing: stirring for homogenizing in a homogenizing pool for 24 hours so that the slurry is uniform, and the liquidity of the slurry is kept; 7) pulverizing; 8) aging: after the slurry turns to the powder, storing the particles sieved according to the size of the particles by a computer to various stock bins, so that powder particles moisture in the stock bin during an ageing process is uniform, and the time is 24-48 hours.

Owner:重庆广鼎道路设施有限公司

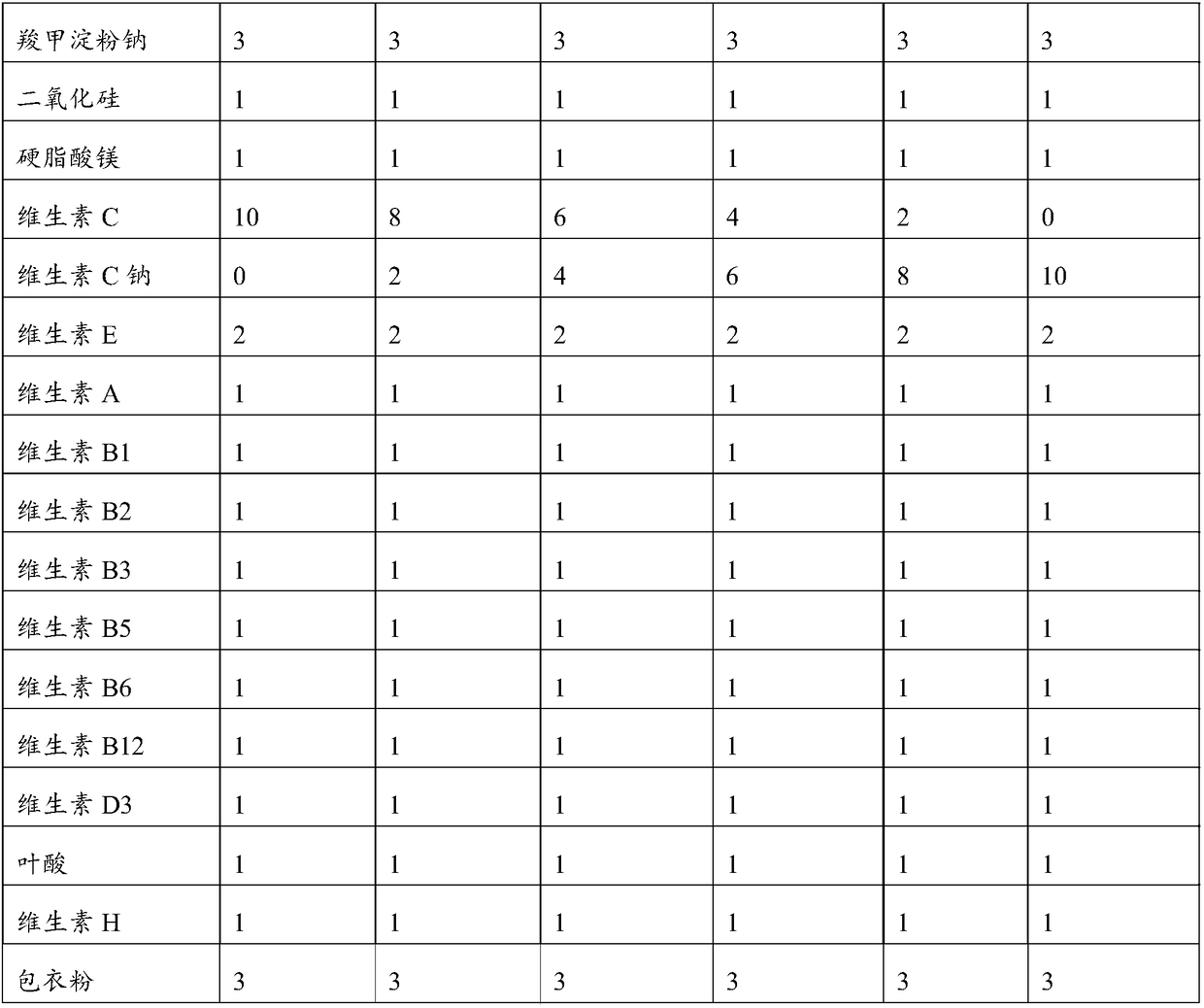

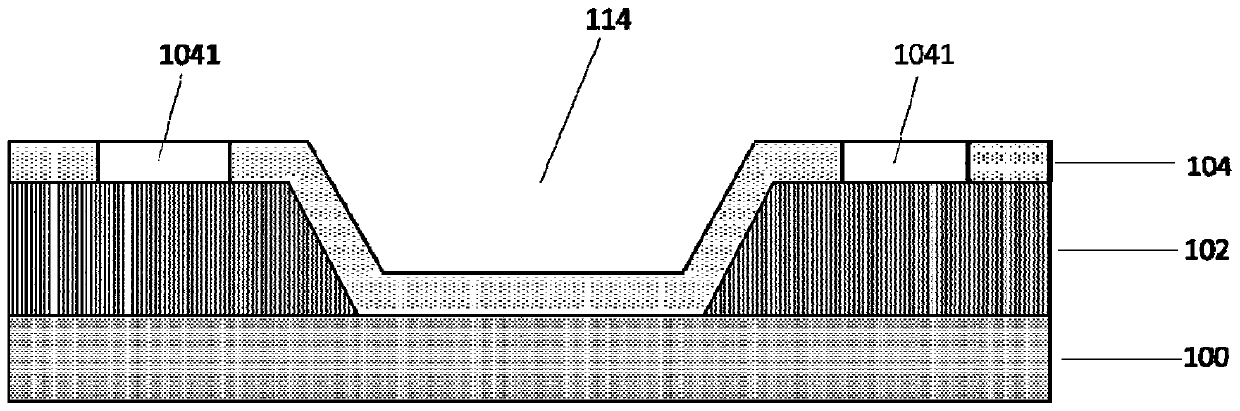

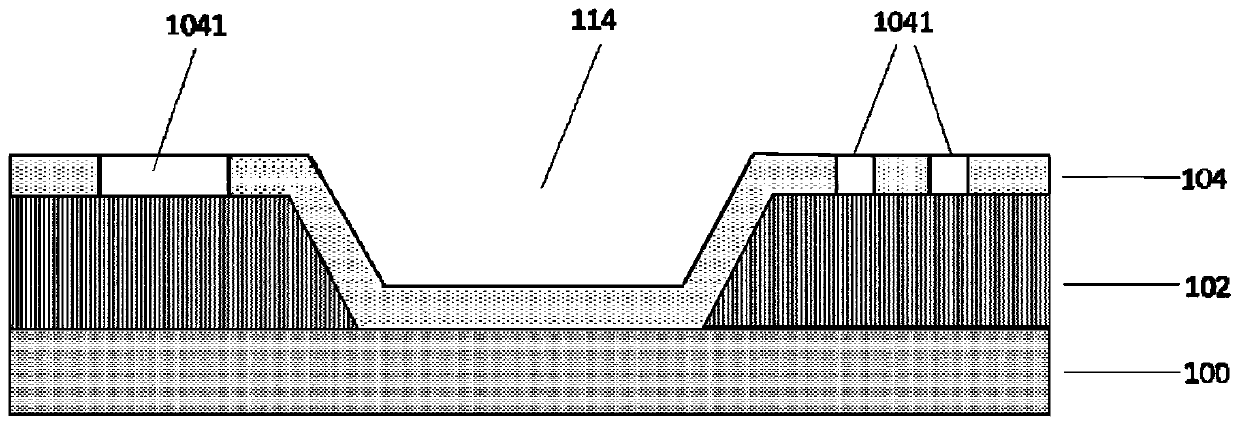

Display panel and display device

ActiveCN110165078AExtended service lifeNo dark spotsSolid-state devicesSemiconductor/solid-state device manufacturingHigh humidityBlack spot

The invention provides a display panel and a display device. The display panel comprises a substrate including a display area and a non-display area located at the periphery of the display area; a planarization layer located on the substrate, wherein a groove surrounds the display area on the corresponding planarization layer in the non-display area; an anode covering the upper surface of the planarization layer, wherein a through hole is formed in the anode and penetrates through the upper and lower surfaces of the anode. The display panel and the display device, while preventing an organic layer from overflowing, ensure that a screen body does not generate a black spot problem in a subsequent high-temperature and high-humidity reliability test, thereby improving the reliability of the panel and prolonging the service life of the display panel.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Novel aluminum profile oxidization coloring technology

ActiveCN105177666ANo dark spotsNot easy to fadeSurface reaction electrolytic coatingElectrolysisSurface oxidation

The invention discloses a novel aluminum profile oxidization and coloring method. The novel aluminum profile oxidization and coloring method comprises the first step of oil removing, the second step of adopting an acid solution to remove an oxidation film on the surface of an aluminum alloy workpiece and then carrying out washing, the third step of carrying out oxidation in an oxidation processing solution, the fourth step of washing, the fifth step of electrolytic coloring and the sixth step of adopting an OY-61 aluminum chemical oxidation sealing agent to carry out sealing treatment. An inventor finds that in the oxidation and coloring stage, EDTA with a certain concentration is used, optimization of other parameters is matched, and an aluminum profile which is not prone to fading, resistant to corrosion, even in coloring, free of dark spots and high in glossiness can be accidentally produced.

Owner:ZHEJIANG XINXIANG NEW ENERGY TECH CO LTD

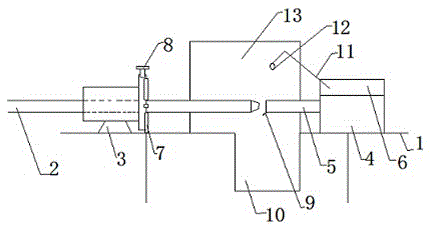

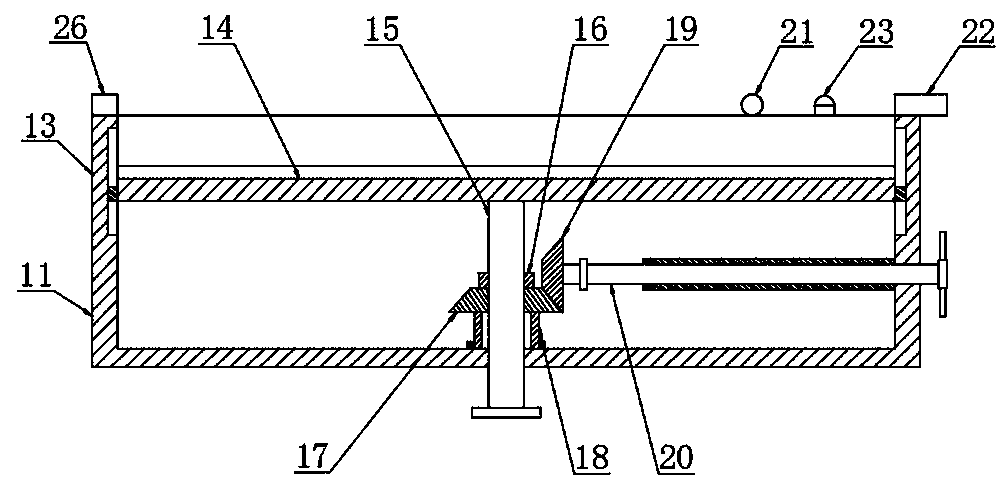

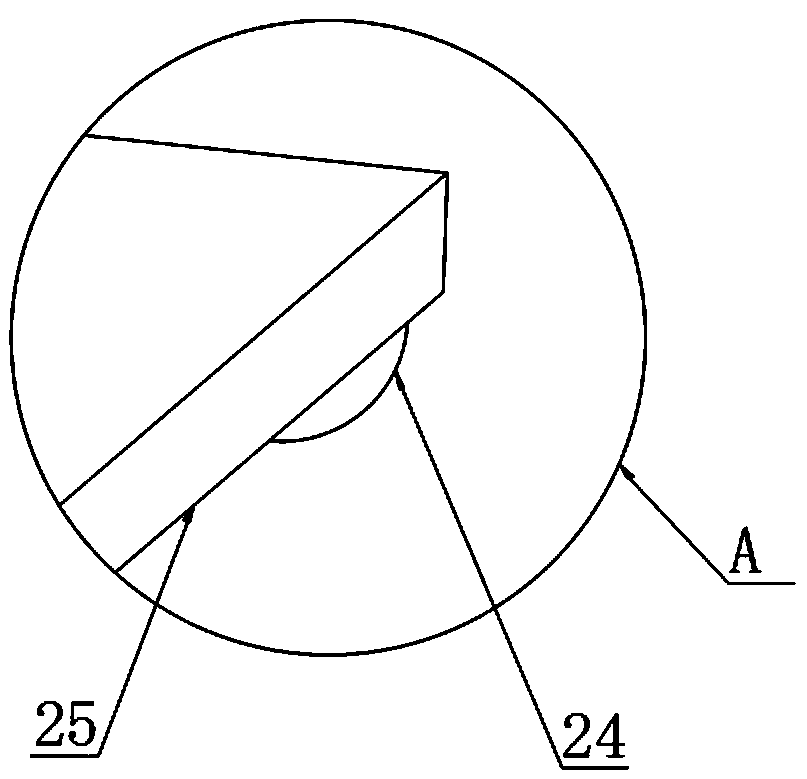

LED light focusing and flooding lamp

InactiveCN101709833BIncrease light intensityHigh luminous flux utilizationPoint-like light sourceElectric lightingOptical axisDark spot

The invention provides an LED light focusing and flooding lamp which is suitable for the fixed or the movable illumination of the electric torch, the head lamp and the like. The LED light focusing and flooding lamp comprises a reflector (1) and an LED (2), wherein the LED (2) is arranged in the reflector (1), the front of the LED (2) is provided with a lens (3), and the lens (3) is arranged on an adjustable lens support (4) which can move along the main optical axis of the LED (2). When focusing the light, the LED light focusing and flooding lamp can ensure that the center of the light spot has high light intensity and high luminous flux utilization ratio, and when flooding the light, the LED light focusing and flooding lamp can ensure that no dark spot appears in the center of the light spot and the illumination of the light spot in the center is uniform.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

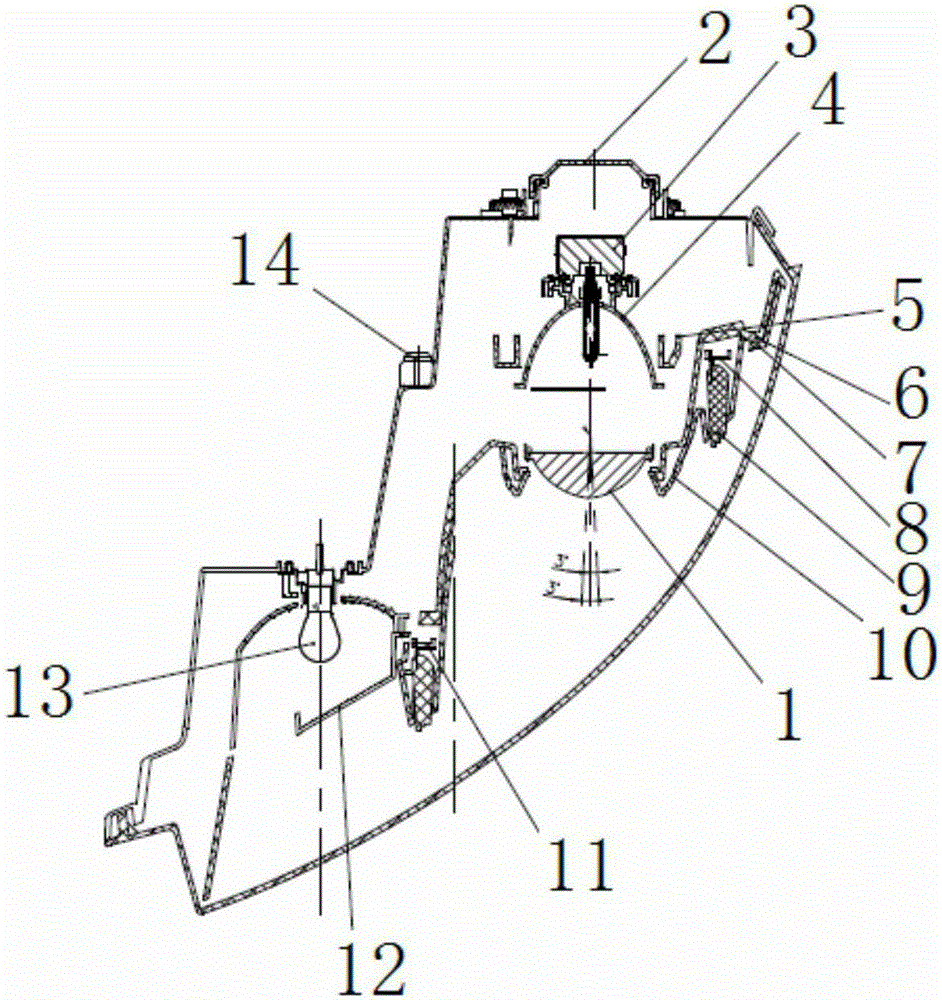

Novel daytime running lamp

The invention discloses a novel daytime running lamp. The novel daytime running lamp comprises a lamp body, a lampshade and an LED lamp. The LED lamp is arranged in a lamp cavity formed by the lamp body and the lampshade. The lamp further comprises a reflecting mirror arranged in the lamp cavity and an LED lamp fixing plate. The reflecting mirror is fixed to the lamp body through a support. The reflecting face of the reflecting mirror faces the lampshade. The LED lamp fixing plate is located above the reflecting mirror. Opposite to the reflecting mirror, the LED lamp is arranged on the LED lamp fixing plate. The lampshade comprises an external lampshade body and an internal lampshade body, and the internal lampshade body is clamped to the reflecting mirror. Light of the LED lamp in the novel daytime running lamp is not directly radiated out but converted into an area light source through the reflecting mirror, emitted light is uniform, no dark points exist, the light-emitting intensity can meet the requirement and can be more easily accepted by human eyes, and vehicle safety is guaranteed.

Owner:WUHU ANRUI OPTOELECTRONICS

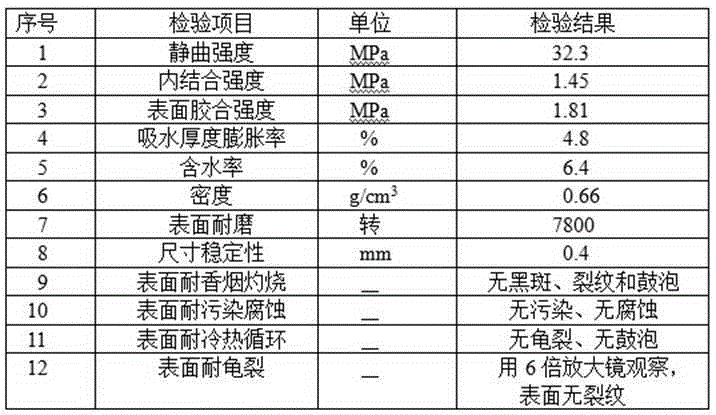

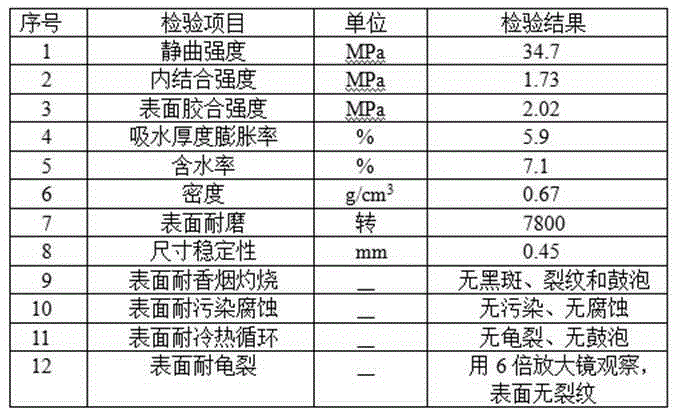

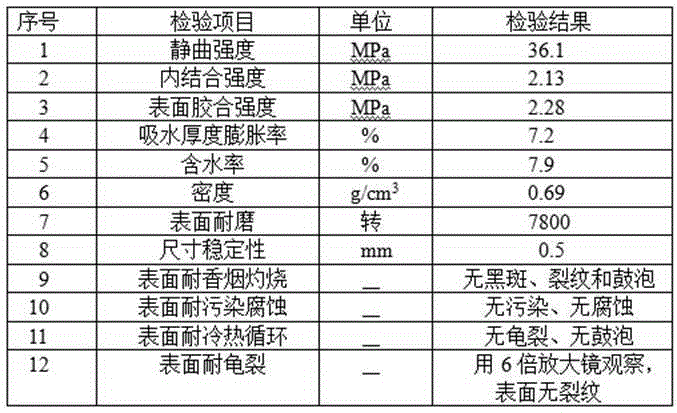

Dry method for manufacturing fiber board through cow dung

ActiveCN105235046AAchieve reuseEasy to prepareFlat articlesDomestic articlesEnvironmental resistanceFiber

The invention relates to a dry method for manufacturing a fiber board through cow dung, and belongs to the field of environmental protection materials. According to the method, the cow dung is cleaned through bamboo vinegar and then cleaned through a neutral cleaning solution; the cow dung is filtered, dried, crushed and screened to obtain fibers; NaOH solid is dissolved in distilled water to obtain a solution, and the solution and the fibers are evenly stirred at the normal temperature and then placed in a drying case to be activated; after ecological adhesives without formaldehyde is added, the solution and the fibers are placed in a high-speed mixer to be mixed, and then stirring is conducted after waterproof agents are added; drying is then carried out to enable the water content of the fibers to be 7%-12%; the fibers are evenly laid and subjected to slab pre-pressing; the obtained fibers are subjected to hot pressing; and after demolding, the fiber board is obtained after 3-5 days of room temperature cooling. The manufacturing method is simple and low in cost, continuous production can be easily achieved, and the product quality is stable; the obtained board has no black spots or cracks and is free of bubbling, pollution, corrosion and fracturing, and the static bending intensity and the internal combination strength of the board meet national standards; the raw materials are waste, so that reutilization of the waste is achieved.

Owner:KUNMING UNIV OF SCI & TECH

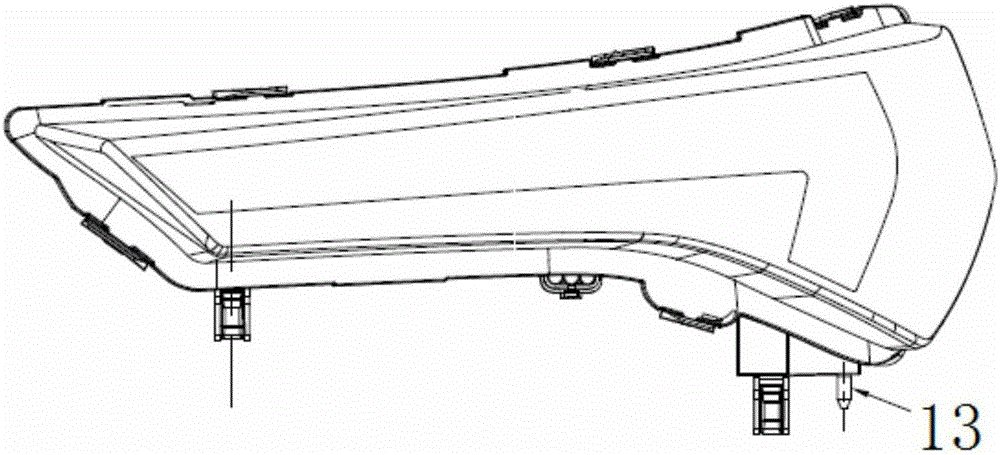

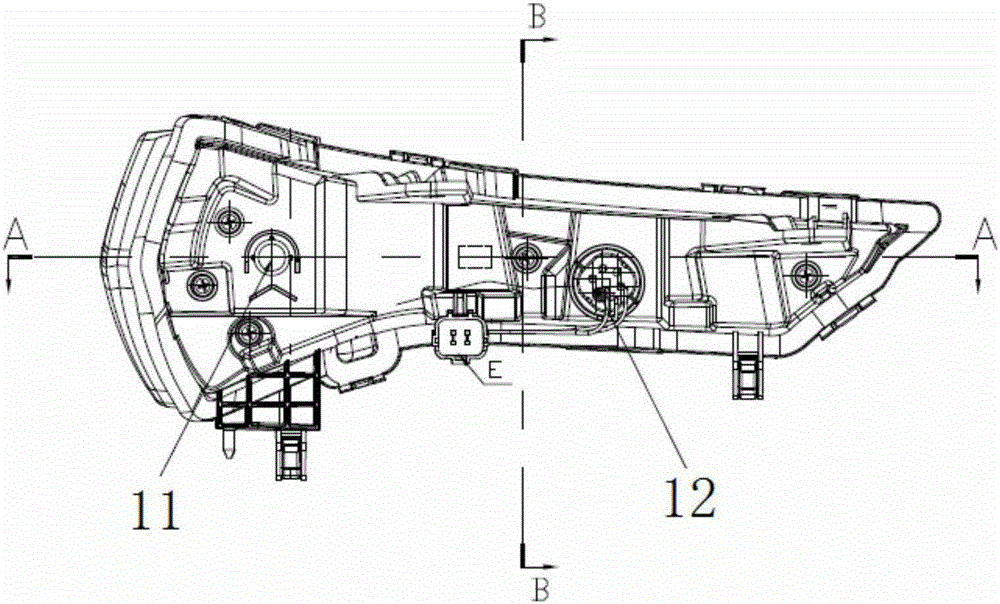

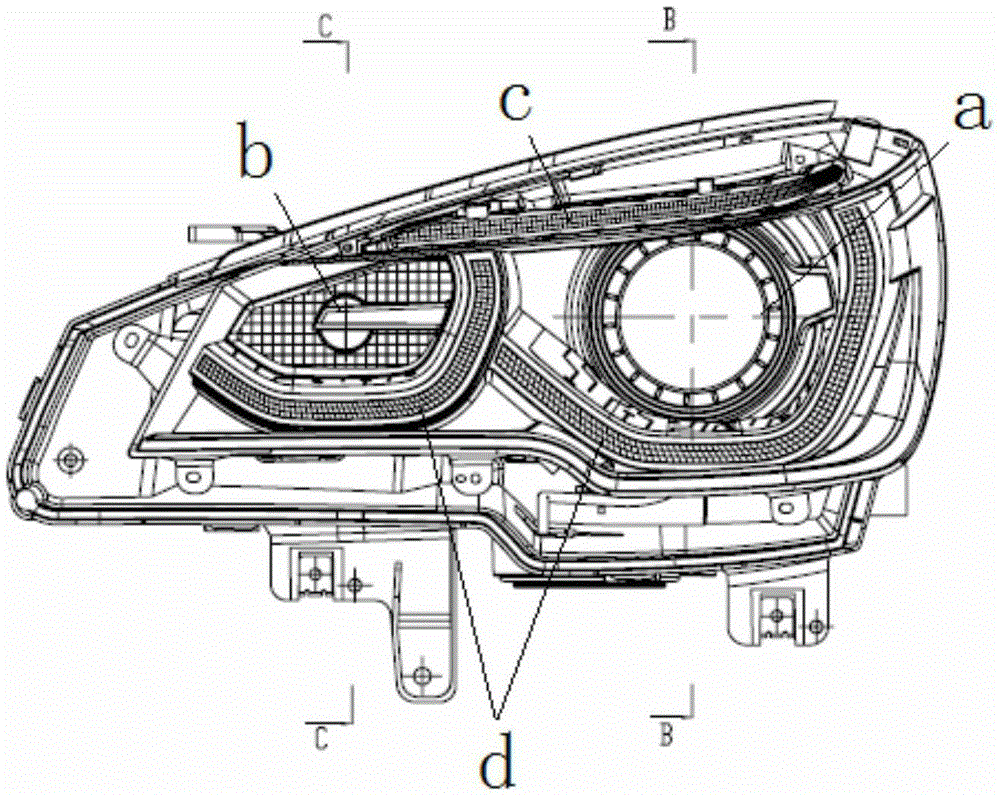

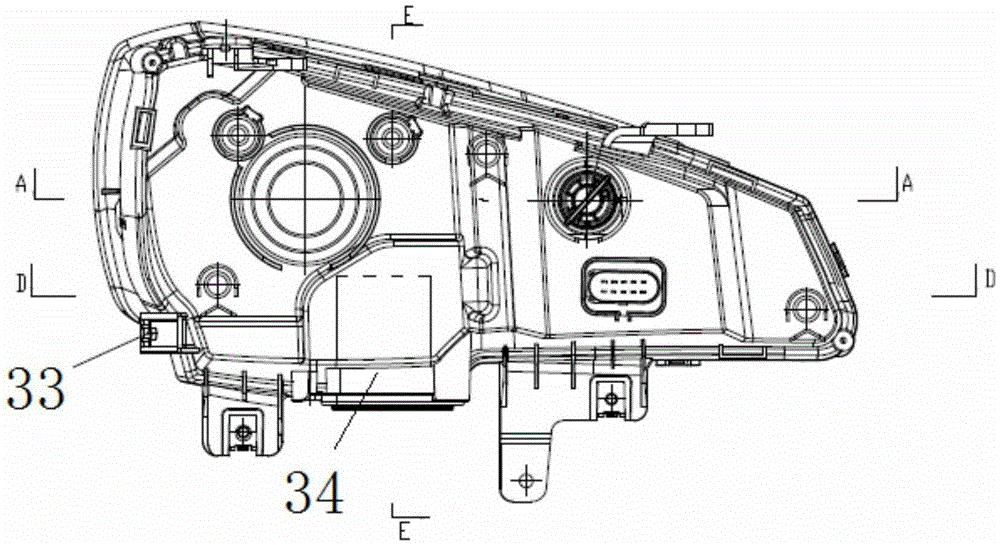

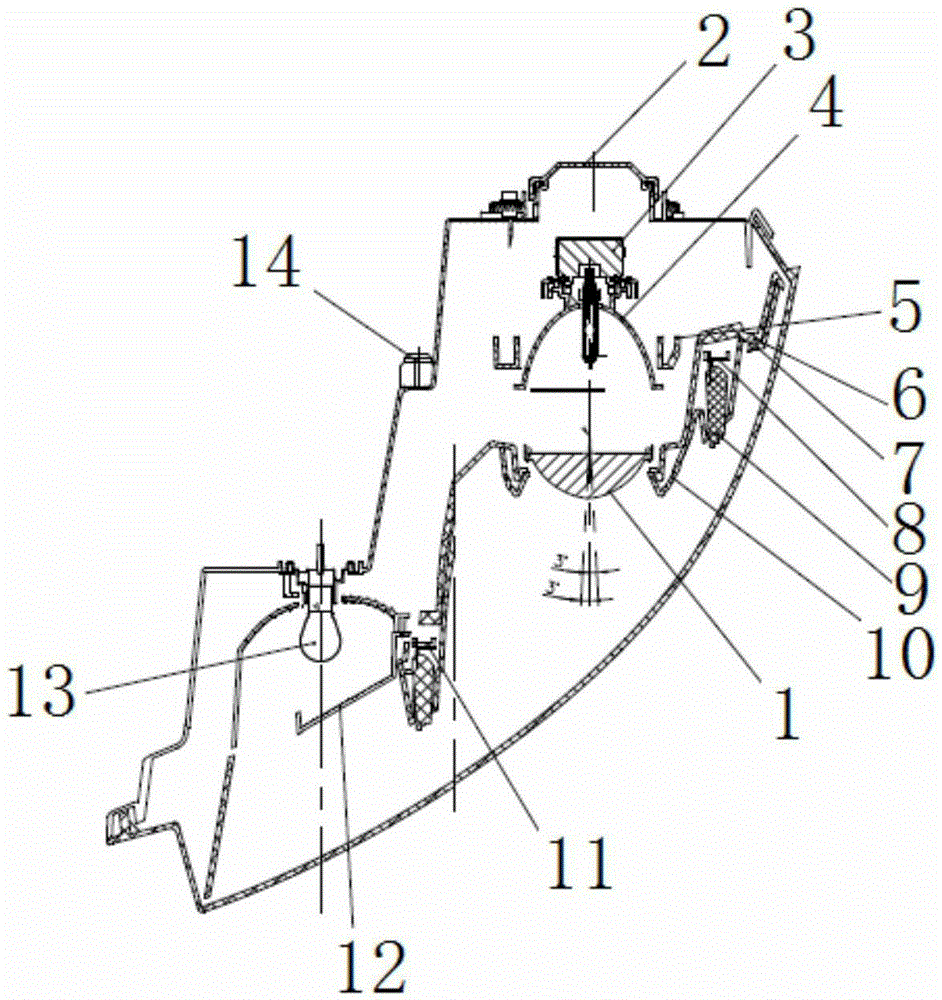

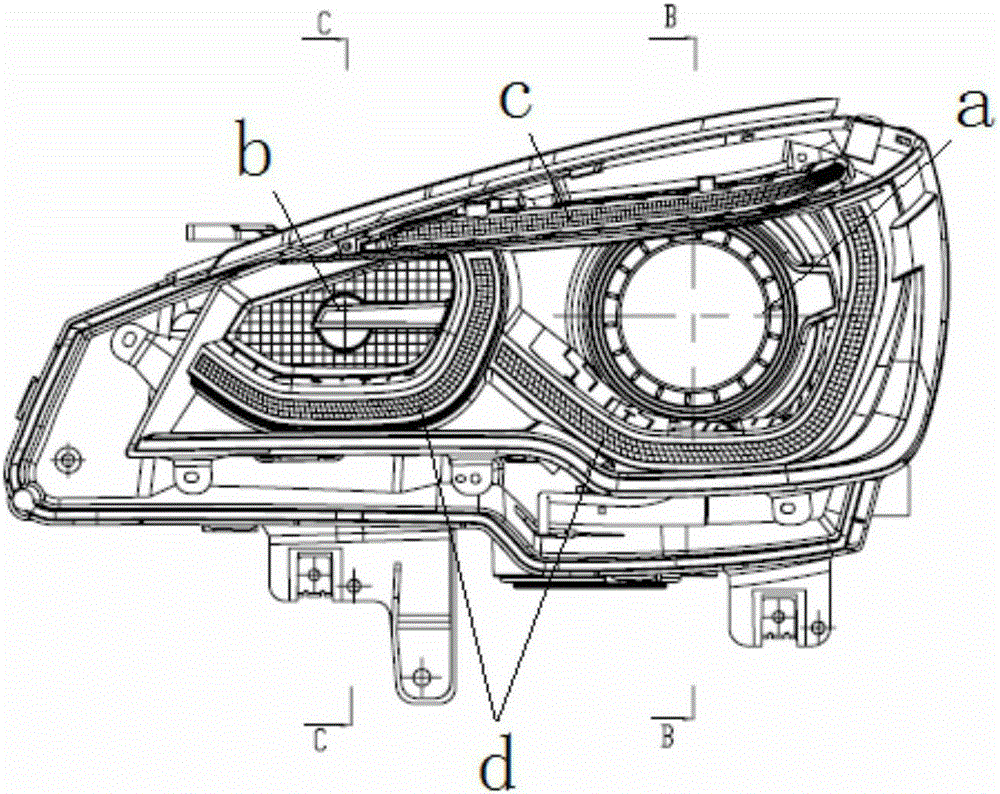

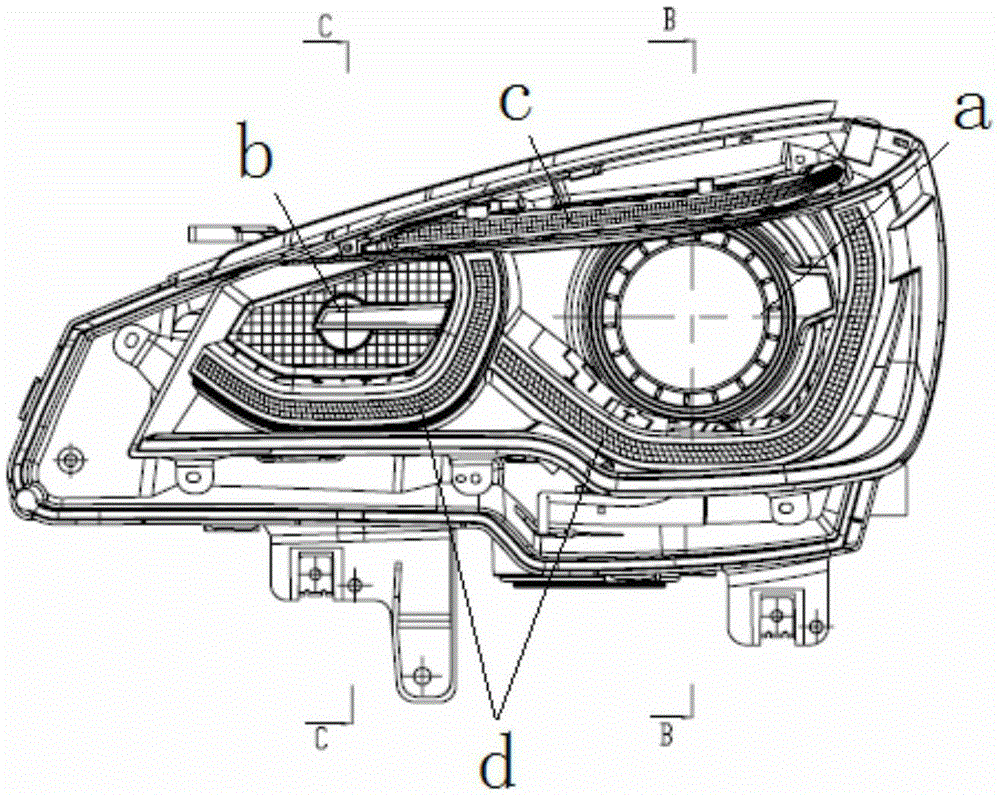

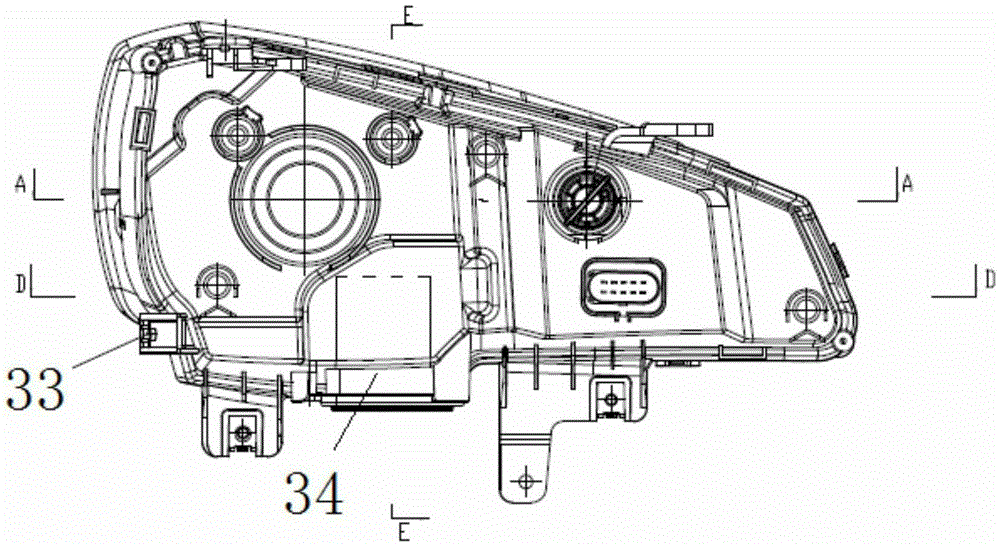

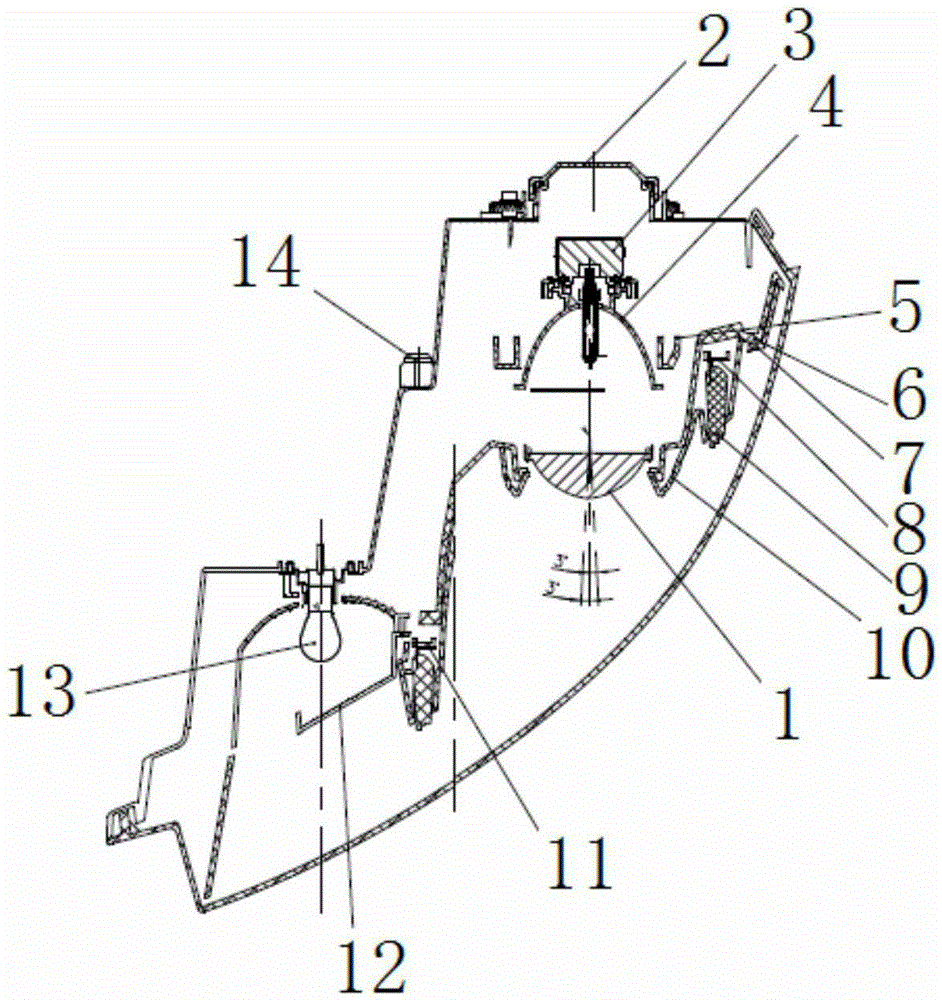

Automobile headlight with compact structure

InactiveCN105423212ACompact structureEasy to install and arrangeMechanical apparatusVehicle headlampsOptoelectronicsLED lamp

The invention discloses an automobile headlight with the compact structure. The automobile headlight comprises a light shell and a transparent light cover. The light shell and the light cover match to form a cavity. A high beam / low beam, a turn light and a daytime running light are arranged in the cavity. The turn light is located on the inner side of the high beam / low beam. The daytime running light is an LED light, and the LED light is fixed to the part, in the cavity, of the light shell through a daytime running light LED support. The high beam / low beam comprises a high beam / low beam bulb and a high beam / low beam projector. The turn light comprises a turn light bulb and a turn reflector. The high beam / low beam projector is of a hemispherical structure. The high beam / low beam bulb is arranged in the high beam / low beam projector. A high beam / low beam light distribution mirror is arranged at the position, corresponding to the high beam / low beam bulb, in the cavity. The high beam / low beam projector is fixed through a high beam / low beam projector support of the cavity. The high beam / low beam, the turn light and the daytime running light are integrated in the headlight, and the automobile headlight is compact in structure, convenient to arrange and mount and low in cost.

Owner:WUHU ANRUI OPTOELECTRONICS

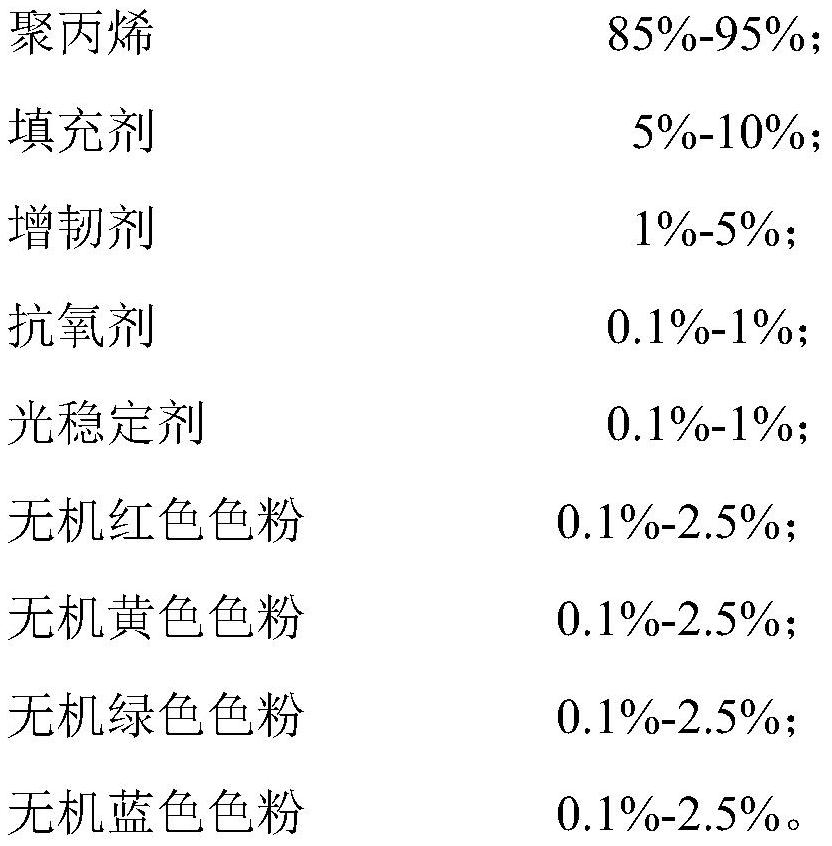

Quaternary compound color master batch and preparation method thereof

The invention relates to a quaternary compound color master batch and a preparation method thereof. The quaternary compound color master batch mainly comprises red, yellow, green and blue toner. According to the scheme of compounding the quaternary toner with the color master batch, the color effect of the carbon black is perfectly copied in light-color and white plastics, and the black spot appearance problem caused by the characteristics of small primary particle size, easiness in agglomeration and difficulty in dispersion of the carbon black is fundamentally solved; meanwhile, the compoundcolor master batch is more excellent in dispersion effect, color control is more convenient, raw materials are cheap and easy to obtain, and extra cost is not increased in production.

Owner:SHANGHAI KINGFA SCI & TECH +1

Rod processing device

The invention discloses a rod processing device which comprises a motor (1), a fly wheel (2), a small gear (3), a big gear (4), a clutch (5), a crankshaft (6), a sliding block (7), an electromagnet (8), a belt transmission (9), a worm and gear (10), a chain wheel (11), a rolling wheel (12) and a rolling wheel (13) and is characterized in that with the motor (1) as power, the fly wheel (2) on a spindle is driven by the belt transmission (9), and rotation movement is transferred to the small gear (3) by the spindle to enable the small gear (3) to be meshed with the big gear (4); the clutch (5) is controlled by the electromagnet (8) to enable the crankshaft (6) and the big gear (4) to synchronously move; and the sliding block (7) moves up and down driven by the crankshaft, a rod cutting tool is mounted on the sliding block to move along with the sliding block, and a rod is sheared. The rod processing device is of a simple structure, is convenient to operate and welds a pipeline needing to be welded after cutting the pipeline so as to enable the thickness of the welding part to be consistent with that of the original pipeline without a gap and a dark spot.

Owner:单康

Vacuum freeze drying forming process for wood fiber composite product

ActiveCN106042138ANo color difference on the surfaceNo dark spotsDrying solid materials without heatWood working apparatusFreeze dryAdhesive

The invention discloses a vacuum freeze drying forming process for a wood fiber composite product. Environment-friendly cold-bonding adhesive, wood fibers and other auxiliaries are together made into a wood fiber composite, the wood fiber composite is put into a mold of a specific cavity to be prefreezed, and after certain time is reached, the wood fiber composite is conveyed into vacuum freeze drying equipment for freeze drying curing forming. According to the vacuum freeze drying forming process, a vacuum freeze drying technology is applied to manufacturing of the wood fiber composite product with the combination with the freeze cross-linking curing performance of the environment-friendly cold-bonding adhesive. Compared with thermosetting forming of traditional wood fiber material, the advantages that the wood fiber composite product is free of a pre-cured layer completely, black spots are not generated, bumps and cracking do not appear, and the surface is free of chromatic aberration are achieved, and a brand new field of manufacturing of wood fiber composite products is exploited.

Owner:宁波大世界集团有限公司 +1

Automobile front combination lamp easy and convenient to mount

InactiveCN105276496ACompact structureEasy to install and arrangeVehicle headlampsRoad vehiclesEngineeringLED lamp

The invention discloses an automobile front combination lamp easy and convenient to mount. The automobile front combination lamp comprises a lamp housing and a transparent lampshade which are matched to form a cavity body, a full beam light / low beam light, a turn light and a daytime running light are arranged in the cavity body, the turn light is located on the inside of the full beam light / low beam light, the daytime running light is an LED light which is fixed on the lamp housing in the cavity body through a daytime tuning light LED support, the full beam light / low beam light comprises a full beam light / low beam bulb and a full beam light / low beam light projector, the turn light comprises a turn bulb and a turn reflector; a detachable rubber cover is arranged in the position, corresponding to the full beam light / low beam bulb, of the lamp housing; the daytime running light comprises an upper daytime running light and a lower daytime running light, the upper daytime running light is located above the full beam light / low beam light and the turn light, and the lower daytime running light is located below the full beam light / low beam light and the turn light; the front combination lamp integrates the full beam light / low beam light, the daytime running light and the turn light, the automobile lamp is simple in structure and convenient to place and mount and low in cost.

Owner:WUHU ANRUI OPTOELECTRONICS

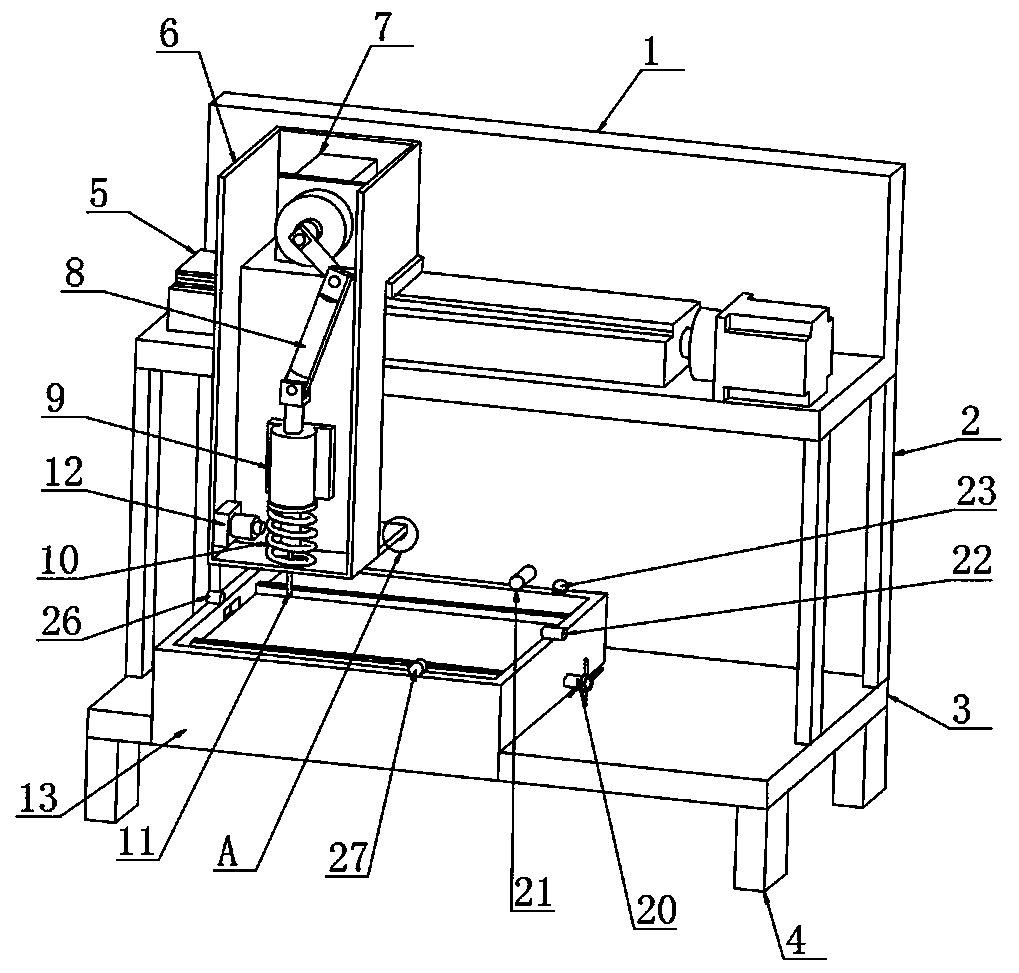

Resin material chip-free cutting equipment and cutting method thereof

The invention discloses resin material chip-free cutting equipment and a cutting method thereof, and particularly relates to the technical field of resin material cutting. The resin material chip-freecutting equipment comprises a supporting seat, wherein a cutting assembly is arranged at the top end of the supporting seat; the cutting assembly comprises a linear guide rail, the linear guide railis arranged at the top end of the supporting seat, a cutter holder is arranged at the top end of the linear guide rail, the cutter holder is arranged at the front end of the supporting seat, a motor is fixed inside the cutter holder, a crank rocker mechanism is arranged at the front end of the motor, a high-frequency induction coil is arranged at the bottom end of a linear bearing, the high-frequency induction coil is arranged at the bottom end inside the cutter holder, and a cutting needle head is fixed at the bottom end of the crank rocker mechanism. According to the equipment and method, the cutting assembly is used for melting and cutting a resin workpiece, chips are not generated in the cutting process, so that the quality of the surrounding environment is effectively ensured, the probability of suffering occupational diseases of people is effectively reduced, and the cutting efficiency and the cutting precision are effectively improved through a calibration assembly.

Owner:漳州市澳捷光学科技有限公司

Bamboo cane anti-breakage treatment technology for plastic rattan seat

InactiveCN107009464ABright colorWon't shrinkPressure wood treatmentWood treatment detailsAcetic acidFiber

The invention provides a bamboo cane anti-breakage treatment technology for a plastic rattan seat. The technology comprises the following steps that bamboo is covered with pond sludge deposited for 2-3 years, then the surface of the pond sludge is covered with yellow soil, and then the bamboo is buried underground; the bamboo is broken into bamboo canes, and the bamboo canes are immersed through fresh bamboo leaf juice and sent into a pressure container of 3.5-4.5 MPa to be pressurized for 2 h; treatment is over, the bamboo canes are easily immersed through ethyl acetate with the concentration being 3.5%; after immersing is conducted for 1 h, the bamboo canes are fished out and then immersed through a dilute sulfuric acid solution with the concentration being 3.2%; the bamboo canes are taken out and placed in a high-pressure chamber, and the pull force of 0.4-0.6 MPa is exerted on the bamboo canes in the high-pressure chamber; and glacial acetic acid is used for continuous cleaning, and airing is conducted. The treated bamboo canes are resistant to bending and scratching, the edges of the bamboo canes cannot be cracked, meanwhile, the treated bamboo canes are bright in color, bamboo cane fiber connection is tighter, the bamboo canes cannot contract under immersion of strong brine, and black spots cannot be generated under roast smoking of local flames with the temperature ranging from 300 DEG C to 350 DEG C.

Owner:安徽持家汉家居工艺品有限公司

Synthesis process for TBHQ (Tertiary Butyl Hydroquinone) crude product

InactiveCN103864579AIncrease profitCause bodily harmOrganic chemistryOrganic compound preparationPhosphoric acidHydroquinone Compound

The invention discloses a synthesis process for a TBHQ (Tertiary Butyl Hydroquinone) crude product. The synthetic process comprises the following steps: 1) pouring 2-4 parts by weight of phosphoric acid and 0.1-0.4 parts by weight of water into a stirring cylinder, then adding 5-7 parts by weight of hydroquinone, and stirring; 2) putting the stirred mixture solution into a reaction kettle, heating to 55-65DEG C, and then feeding 7-9 parts by weight of tert-butyl alcohol into the reaction kettle; 3) after heating to 75-85DEG C, and insulating for two to three hours for reaction; 4) performing centrifugal separation, washing and dehydration on a reaction product, to obtain the TBHQ crude product. According to the preparation process for the TBHQ crude product, water instead of methylbenzene is adopted as a solvent, so that the pollution is less, the raw material utilization ratio is high, and the purity of the obtained TBHQ crude product is higher.

Owner:GUANGZHOU TAIBANG FOOD TECH

Dense black-spot-free iron-based powdery metallurgical self-lubricating CNG engine valve seat ring and preparation method thereof

InactiveCN106636996AHigh strengthIncrease frictionTransportation and packagingMetal-working apparatusCobaltHeat treated

The invention discloses a dense black-spot-free iron-based powdery metallurgical self-lubricating CNG engine valve seat ring. The dense black-spot-free iron-based powdery metallurgical self-lubricating CNG engine valve seat ring is prepared from, by weight, 6.4-6.6 parts of chrome, 4.4-4.6 parts of cobalt, 0.7-1.2 parts of nickel, 0.3-0.5 part of neodymium, 2.3-2.6 parts of boron, 3.6-4.3 parts of polymerization iron powder, 16-18 parts of copper, 1.3-1.5 parts of nano molybdenum disulfide, 0.7-0.8 part of calcium fluoride, 1.2-1.4 parts of silicon carbide, 0.2-0.3 part of zinc chloride, 0.5-0.8 part of triethyl silane, 1-2 parts of glass fiber, 2-3 parts of high carbon ferro-chrome alloy powder and 62-65 parts of iron. The surface of the modified nano molybdenum disulfide is coated with a layer of copper film to serve as a solid lubricant which is added to a substrate material, meanwhile the silicon carbide, neodymium, boron and other ingredients are further added, metal particle phase change is changed by adopting sintering, infiltration and heat treatment processes, and the prepared product is uniform in texture, dense, stable and free of black spot and other defects.

Owner:安徽马仪科技股份有限公司

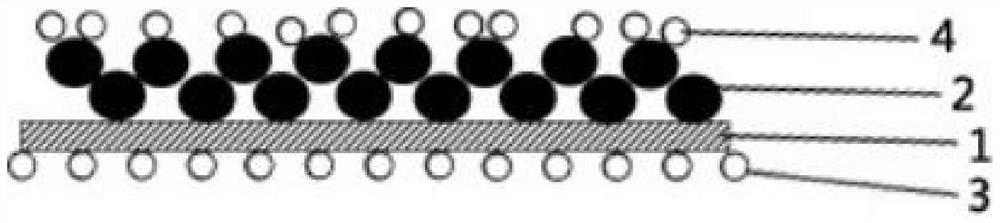

Lithium ion battery diaphragm, preparation method thereof and lithium ion battery

InactiveCN113394516AIncrease transfer rateHigh mechanical strengthFinal product manufactureCell component detailsElectrolytic agentCeramic composite

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a lithium ion battery diaphragm and a preparation method thereof. The lithium ion battery diaphragm comprises a base membrane layer and a ceramic composite layer, the ceramic composite layer is arranged on the surface of the base membrane layer, the porosity of the ceramic composite layer is 50-80%, and the pore size is 0.1-0.5 [mu]m. According to the lithium ion battery diaphragm disclosed by the invention, the base membrane layer is coated with the ceramic composite layer, and the ceramic composite layer has relatively large porosity and relatively large pore diameter, so that the overall mechanical strength of the diaphragm is improved, the liquid absorption rate is also improved, and the lithium ion transmission rate is increased therefore, the conditions of insufficient electrolyte infiltration, interface black spots, lithium precipitation and low cycle retention rate after high-power and high-rate output or multiple charge-discharge cycles are improved.

Owner:HUIZHOU LIWINON ELECTRONIC TECH CO LTD

Method for quickly pickling salted duck eggs which can be permanently preserved

The present invention discloses a method for quickly pickling salted duck eggs which can be permanently preserved. Firstly, a proper amount of carrageenan is added in pickling liquid as a thickening agent to adjust the shape of the pickling liquid to improve the permeability of the pickling liquid; then, an acid soaking decompression method is used to pickle duck eggs; under cooperation of vacuumcondition, whole materials produce a certain expansion, which is beneficial to the rapid penetration of the materials, greatly shortens the pickling time and improves the pickling efficiency. Egg shells of the prepared salted duck eggs are complete, clean and free of black spots; egg white is complete, non-honeycomb-shaped and smooth in section; egg yolk is oily, moist, loose and sand-like in taste and has oil fragrance; and finally, processes of sodium hypochlorite sterilization and polyvinyl alcohol-based nano-silicon dioxide composite material film coating are conducted on the surfaces of the successfully pickled salted duck eggs, which can effectively inhibit the moisture loss in the eggs and continuously inhibit growth of microorganisms, thereby prolonging the shelf life of the saltedduck eggs and further improving economic benefits.

Owner:HEFEI FULAIDUO FOOD

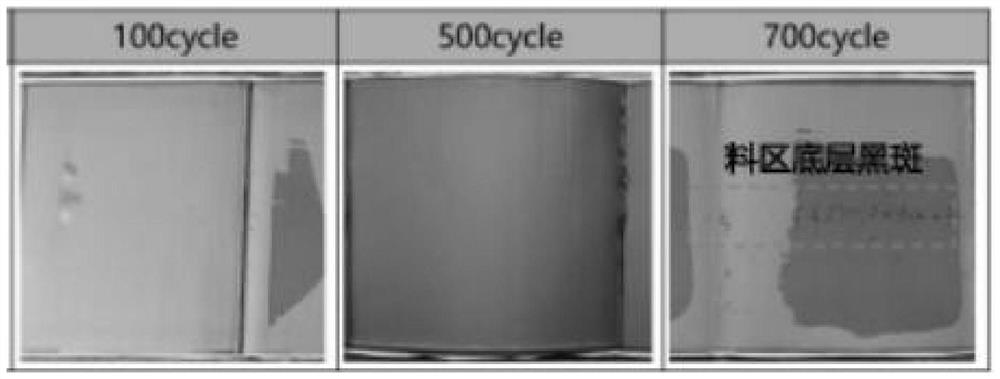

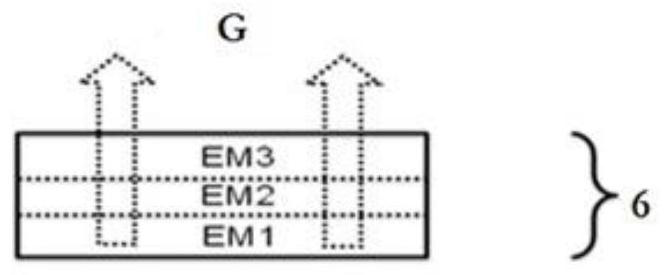

An organic electroluminescent device, a preparation method thereof, and a display device prepared therefrom

ActiveCN112310301BReduce the temperatureReduce processing costsSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceRefractive index

The invention discloses an organic electroluminescence device, which comprises a substrate, a display unit, a cover layer, a protection layer and an encapsulation layer in order from bottom to top, and is characterized in that the cover layer contains a refractive index ≥ 1.8 and an absolute value of LUMO. Organic material ≥2.9 eV; the protective layer comprises one or more of cesium fluoroaluminate, magnesium fluoride, aluminum fluoride, and silver fluoride. The organic electroluminescent device of the invention overcomes the problem in the industry that the organic material of the cover layer interacts with the LiF of the adjacent layer due to TFE encapsulation, thereby causing the device to appear black spots, so that the yield is greatly improved and the production cost is reduced.

Owner:JIANGSU SUNERA TECH CO LTD

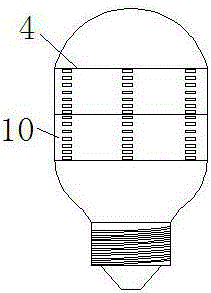

Module bulb lamp

InactiveCN106609933ANo dark spotsReasonable structurePlanar light sourcesElectric lightingEngineeringLight head

The invention relates to a module bulb lamp. The module bulb lamp comprises a lamp holder and a lamp base; a lamp pin rotary connection groove is formed in the upper end face of the lamp base; a basis light emitting module is arranged above the lamp base and comprises a light emitting module unit and a PC lampshade arranged above the light emitting module unit; the light emitting module unit comprises a light emitting body and a PC cover arranged outside the light emitting body; and the lower portion of the light emitting body is provided with a lamp pin. The module bulb lamp is of a modularized type structure, can be freely combined and is safe and reliable.

Owner:HONGLI LIGHTING GRP

Automobile front combination lamp

InactiveCN105318253ACompact structureEasy to install and arrangeVehicle headlampsRoad vehiclesEngineeringAluminum substrate

The invention discloses an automobile front combination lamp. The automobile front combination lamp comprises a lamp housing and a transparent lampshade, wherein a cavity is formed through the fit of the lamp housing and the lampshade, a high-beam / low-beam lamp, a turn lamp and a daytime running lamp are arranged in the cavity, the turn lamp is positioned on the inner side of the high-beam / low-beam lamp, an LED lamp is used as the daytime running lamp, the LED lamp is fixed to the lamp housing in the cavity through a daytime running lamp LED bracket, the high-beam / low-beam lamp comprises a high-beam / low-beam lamp bulb and a high-beam / low-beam lamp projector, and the turn lamp comprises a turn bulb and a turn reflector; and the LED lamp comprises a circuit board and an LED lamp group, the LED lamp group is arranged on the circuit board, an aluminum substrate is arranged on the lamp housing, and the circuit board is arranged on the aluminum substrate. The front combination lamp is integrated with the high-beam / low-beam lamp, the daytime running lamp and the turn lamp. The automobile lamp is compact in structure, convenient to lay and mount and low in cost.

Owner:WUHU ANRUI OPTOELECTRONICS

An aluminum profile oxidation coloring process

ActiveCN105177666BNo dark spotsNot easy to fadeSurface reaction electrolytic coatingElectrolysisSurface oxidation

The invention discloses a novel aluminum profile oxidization and coloring method. The novel aluminum profile oxidization and coloring method comprises the first step of oil removing, the second step of adopting an acid solution to remove an oxidation film on the surface of an aluminum alloy workpiece and then carrying out washing, the third step of carrying out oxidation in an oxidation processing solution, the fourth step of washing, the fifth step of electrolytic coloring and the sixth step of adopting an OY-61 aluminum chemical oxidation sealing agent to carry out sealing treatment. An inventor finds that in the oxidation and coloring stage, EDTA with a certain concentration is used, optimization of other parameters is matched, and an aluminum profile which is not prone to fading, resistant to corrosion, even in coloring, free of dark spots and high in glossiness can be accidentally produced.

Owner:ZHEJIANG XINXIANG NEW ENERGY TECH CO LTD

An organic electroluminescent device containing a covering layer and its application

ActiveCN109860425BImprove light extraction efficiencyExcellent viewing angleSolid-state devicesSemiconductor/solid-state device manufacturingLight equipmentRefractive index

The invention relates to an organic electroluminescence device with a covering layer, which comprises: a substrate layer; a first electrode on the substrate; an organic light-emitting function layer, the organic light-emitting function layer a layer on the first electrode; a second electrode on the organic light-emitting functional layer; and a cover layer on the second electrode, wherein the cover layer Including organic compounds, the organic compounds of the covering layer contain different types of heteroarylamine structures, have high glass transition temperature and molecular thermal stability; low absorption and high refractive index in the field of visible light, and are used in OLED devices After the CPL layer, the light extraction efficiency of the OLED device can be effectively improved; the present invention also relates to the use of the organic electroluminescent device containing the covering layer of the present invention for display or lighting equipment.

Owner:JIANGSU SUNERA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com