Honeysuckle vacuum freeze drying process

A vacuum freeze-drying and vacuum-drying technology, which is applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of water loss of plant tissue cells, no subsequent discharge, large production investment, etc., and achieve high-quality products The effect of best quality, high utilization rate and high dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A honeysuckle vacuum freeze-drying process, comprising the following steps:

[0029] (1) Pretreatment

[0030] (2) Arrangement, the placement thickness of honeysuckle is 1-3mm;

[0031] (3) Pre-freeze, put the honeysuckle into a vacuum freeze dryer, reduce the temperature of the honeysuckle to -30°C to -35°C, and keep it for 4-5 hours;

[0032] (4) Vacuum drying, when the temperature in the cold trap is lowered to -60°C, the vacuum degree is maintained at 20-30Pa, and the vacuum is started for sublimation drying, and the temperature is raised to 35-45°C in the drying chamber, and the vacuum degree reaches 1-10Pa After the end, the vacuum freeze-dried honeysuckle was obtained.

[0033]The specific steps of sublimation drying are as follows: the temperature of honeysuckle is maintained at -30°C to -35°C, and kept for 3.5 hours; the temperature of honeysuckle is recovered and maintained at -30 to -20°C, and kept for 2 hours; ~-10℃, keep for 2 hours; honeysuckle temperat...

Embodiment 2

[0036] Example 2 Analysis of Honeysuckle Characters by Different Drying Methods

[0037] The flowers were processed according to the conditions in Table 1, and each sample was repeated 3 times in parallel.

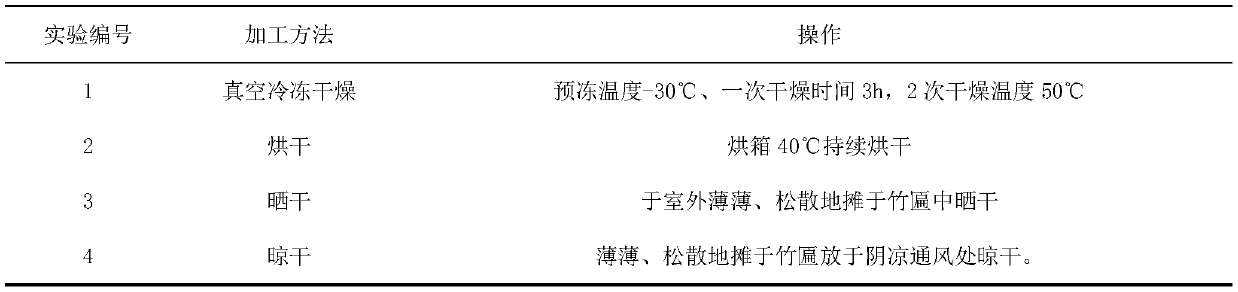

[0038] Table 1 Different honeysuckle drying methods

[0039]

[0040] Analysis of traits of honeysuckle by different drying methods

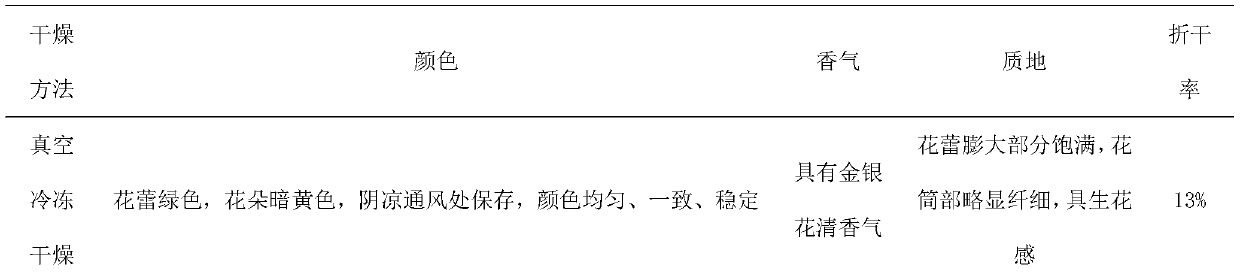

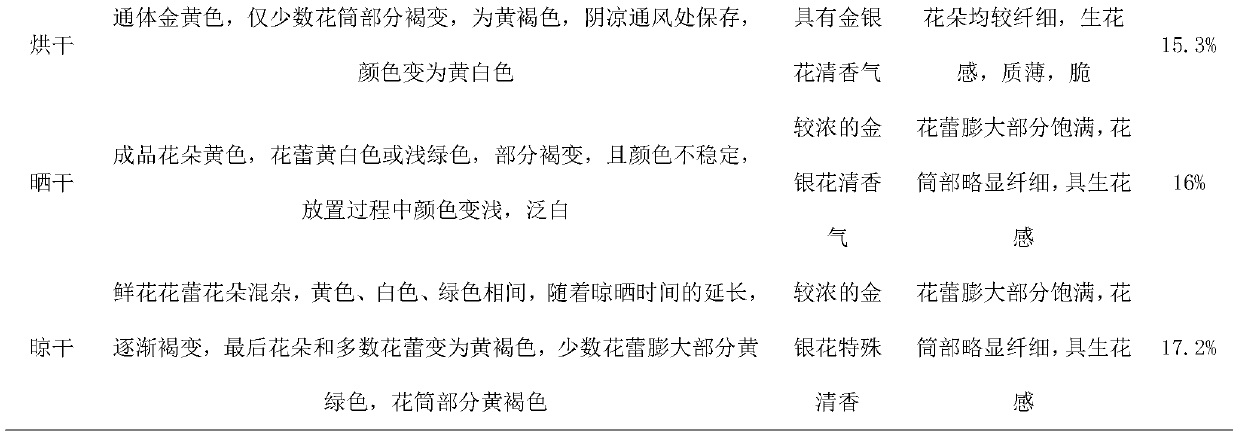

[0041] Table 2 Appearance traits of different dried honeysuckle

[0042]

[0043]

Embodiment 3

[0044] Method and Analysis of Organic Acid Content in Flos Lonicerae by Different Drying Methods in Example 3

[0045] (1) Chromatographic conditions

[0046] The content of the active ingredient was determined by HPLC, and the determination conditions were as follows: Chromatographic column: Agilent ZORBAX XDB-C18 (4.6mm×250mm, 5 μm); mobile phase A: 0.1% formic acid water, mobile phase B: acetonitrile; column temperature: 30°C; Injection volume: 20 μl; detection wavelength: 240nm, 325nm, 350nm; see Table 3 for mobile phase elution gradient. The number of theoretical plates calculated based on chlorogenic acid shall not be less than 5000.

[0047] Table 3 Gradient elution table of HPLC mobile phase

[0048]

[0049] (2) Preparation of reference substance solution

[0050] Accurately weigh 9.79mg of neochlorogenic acid, 10.75mg of cryptochlorogenic acid, 11.09mg of caffeic acid, 9.29mg of isochlorogenic acid B, and 4.32mg of deoxidized loganin, place them in 1ml volumetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com